Toyota Venza: Transmission Control Switch Circuit

DESCRIPTION

When the shift lever is in S and it is moved toward "-" or "+", it is possible to select different shift ranges (1st through 6th ranges).

Moving the shift lever toward "+" increases the shift range by one, and moving the shift lever toward "-" decreases the shift range by one.

WIRING DIAGRAM

.png)

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (BATTERY - TRANSMISSION CONTROL SWITCH) |

|

(a) Disconnect the transmission control switch connector of shift lock control unit assembly. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D14-6 (IG) - Body ground or other terminals |

Ignition switch ON |

11 to 14 V |

|

Ignition switch off |

Below 1 V |

|

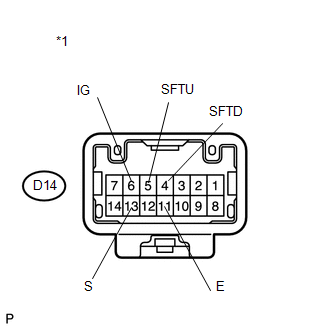

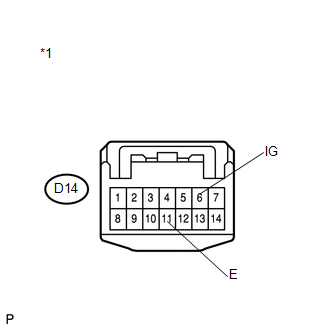

*1 |

Front view of wire harness connector (to Transmission Control Switch) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

(a) Measure the resistance between each terminal of the transmission control switch when the shift lever is moved to each position. Standard Resistance:

|

|

| NG | .gif) |

REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

|

4. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - ECM) |

(a) Connect the transmission control switch connector.

(b) Disconnect the ECM connector.

(c) Turn the ignition switch to ON.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A41-25 (S) - Body ground or other terminals |

|

11 to 14 V |

|

A41-25 (S) - Body ground or other terminals |

|

Below 1 V |

|

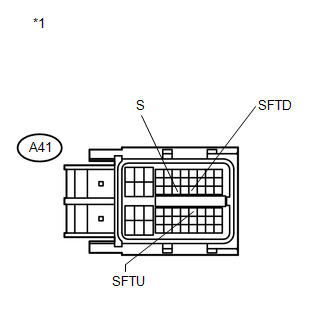

*1 |

Front view of wire harness connector (to ECM) |

(e) Turn the ignition switch off.

(f) Disconnect the spiral cable connector.

(g) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A41-38 (SFTU) - Body ground or other terminals |

Shift lever held in "+" (Up-shift) |

Below 1 Ω |

|

Shift lever not held in "+" |

10 kΩ or higher |

|

|

A41-27 (SFTD) - Body ground or other terminals |

Shift lever held in "-" (Down-shift) |

Below 1 Ω |

|

Shift lever not held in "-" |

10 kΩ or higher |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

System Voltage (P0560)

System Voltage (P0560)

DESCRIPTION

The battery supplies electricity to the TCM even when the ignition switch is

off. This power allows the TCM to store data such as DTC history and freeze frame

data. If the battery vol ...

ECU Power Source Circuit

ECU Power Source Circuit

DESCRIPTION

When the ignition switch is turned to ON, voltage from the ECM's MREL terminal

is applied to the EFI MAIN relay. This causes the contacts of the EFI MAIN relay

to close, which sup ...

Other materials about Toyota Venza:

Oxygen Sensor Heater Control Circuit Low (Bank 1 Sensor 2) (P0037,P0038,P0141,P102D)

DESCRIPTION

Refer to DTC P0136 (See page ).

HINT:

When any of these DTCs are stored, the ECM enters fail-safe mode. The

ECM turns off the heated oxygen sensor heater in fail-safe mode. Fail-safe

mode continues until the ignition switch is t ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 COOLER THERMISTOR

(a) Install the No. 1 cooler thermistor as shown in the illustration.

Part

Length

A

34.3 mm

...

Open in Stop Light Switch Circuit (C1249/49)

DESCRIPTION

The skid control ECU (housed in the actuator assembly) inputs the stop light

switch signal and the condition of brake operation.

The skid control ECU has an open detection circuit, which outputs this DTC when

detecting an open in the stop lig ...

0.1155

.gif)