Toyota Venza: Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve SLU) (P2759)

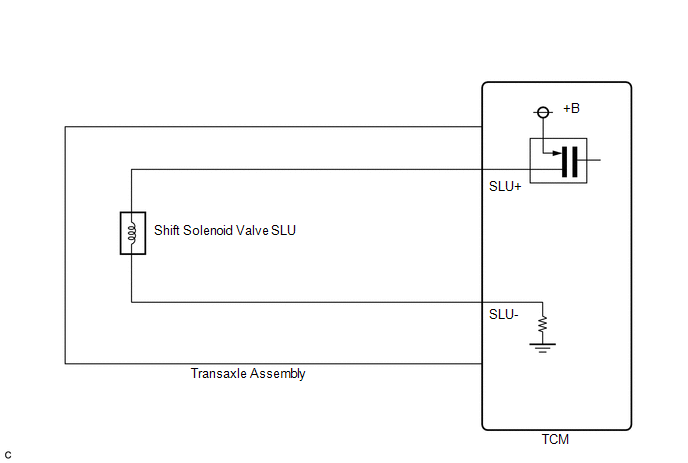

DESCRIPTION

The amount of current flow to the solenoid is controlled by the duty ratio of the TCM output signal. The higher the duty ratio becomes, the higher the lock-up hydraulic pressure becomes during the lock-up operation.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

P2759 |

Open or short is detected in shift solenoid valve SLU circuit for 1 second or more while driving (1-trip detection logic). |

|

MONITOR DESCRIPTION

When an open or short in a shift solenoid valve (SLU) circuit is detected, the TCM determines there is a malfunction. The TCM will turn on the MIL and store this DTC.

MONITOR STRATEGY

|

Related DTCs |

P2759: Shift solenoid valve SLU/Range check |

|

Required sensors/Components |

Shift solenoid valve SLU |

|

Frequency of operation |

Continuous |

|

Duration |

1 sec. |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All|

The monitor will run whenever the following DTCs are not present |

None |

|

Ignition switch |

ON |

|

Starter |

OFF |

|

Battery voltage |

12 V or more |

|

Battery voltage |

10 V or more and less than 12 V |

|

Target current |

Less than 0.75 A |

|

Battery voltage |

8 V or more |

|

Target current |

0.25 A or more |

TYPICAL MALFUNCTION THRESHOLDS

Condition (A) and (B)|

Output duty cycle |

100% or more |

|

Output duty cycle |

0% or less |

COMPONENT OPERATING RANGE

|

Output duty cycle |

More than 3% and less than 100% |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Perform the universal trip to clear permanent DTCs (See page

.gif) ).

).

PROCEDURE

|

1. |

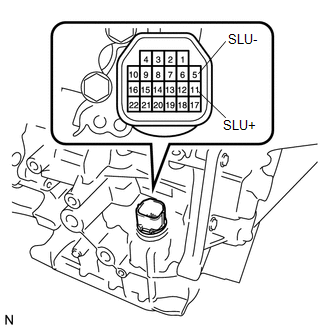

INSPECT TRANSMISSION WIRE (SLU) |

|

(a) Remove the TCM from the transaxle. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

11 (SLU+) - 5 (SLU-) |

20°C (68°F) |

5.0 to 5.6 Ω |

|

11 (SLU+) - Body ground or other terminals |

Always |

10 kΩ or higher |

|

5 (SLU-) - Body ground or other terminals |

Always |

10 kΩ or higher |

|

11 (SLU+) - All other terminals except 5 (SLU-) |

Always |

10 kΩ or higher |

|

5 (SLU-) - All other terminals except 11 (SLU+) |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE TCM |

|

|

2. |

INSPECT SHIFT SOLENOID VALVE SLU |

|

(a) Remove shift solenoid valve SLU. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

20°C (68°F) |

5.0 to 5.6 Ω |

|

*1 |

Shift Solenoid Valve SLU |

(c) Connect a battery positive (+) lead with a 21 W bulb to terminal 2 and a negative (-) lead to terminal 1 of the solenoid valve connector. Then check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| OK | .gif) |

REPLACE TRANSMISSION WIRE |

| NG | .gif) |

REPLACE SHIFT SOLENOID VALVE SLU |

Lost Communication with ECM / PCM "A" (U0100)

Lost Communication with ECM / PCM "A" (U0100)

DESCRIPTION

The engine control unit communicates with the TCM using the Controller Area Network

(CAN).

If there is a problem in this communication, the TCM sets a DTC.

DTC No.

...

Pressure Control Solenoid "D" Electrical (Shift Solenoid Valve SLT) (P2716)

Pressure Control Solenoid "D" Electrical (Shift Solenoid Valve SLT) (P2716)

DESCRIPTION

Refer to DTC P2714 (See page ).

DTC No.

DTC Detection Condition

Trouble Area

P2716

Open or short is detected in shift soleno ...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR DOOR SCUFF PLATE

2. DISCONNECT REAR DOOR OPENING TRIM WEATHERSTRIP

3. REMOVE TONNEAU COVER ASSEMBLY (w/ Tonneau Cover)

4. REMOVE DECK BOARD ASSEMBLY

5. REMOVE NO. 3 DECK BOARD SUB-ASSEMBLY

6. REMOVE DECK S ...

Vehicle Speed Sensor "A" Intermittent / Erratic / High (P0503)

DESCRIPTION

If a malfunction (a rapid change in vehicle speed) in the vehicle speed signal

being output from the skid control ECU is detected while the cruise control is in

operation, the ECM determines that there is a momentary interruption or noise, and ...

Front Stabilizer Bar(for 2gr-fe 2wd)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT FRAME ASSEMBLY (When Using the Engine Support Bridge)

(See page )

2. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE (When Not Using the Engine Support Bridge)

(See page )

3. ...

0.1296

.gif)

.png)