Toyota Venza: Lost Communication with ECM / PCM "A" (U0100)

DESCRIPTION

The engine control unit communicates with the TCM using the Controller Area Network (CAN).

If there is a problem in this communication, the TCM sets a DTC.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

U0100 |

Following conditions are met for 1.25 seconds (1 trip detection logic):

|

|

MONITOR STRATEGY

|

Related DTCs |

U0100: Verify communication |

|

Required Sensors/Components (Main) |

TCM |

|

Required Sensors/Components (Related) |

- |

|

Frequency of Operation |

Continuous |

|

Duration |

1.25 seconds |

|

MIL Operation |

Immediate |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever following DTCs not present |

None |

|

Battery Voltage |

10.5 V or more |

|

Ignition Switch |

ON |

|

Starter |

OFF |

TYPICAL MALFUNCTION THRESHOLDS

|

Communication between TCM and ECM |

No communication |

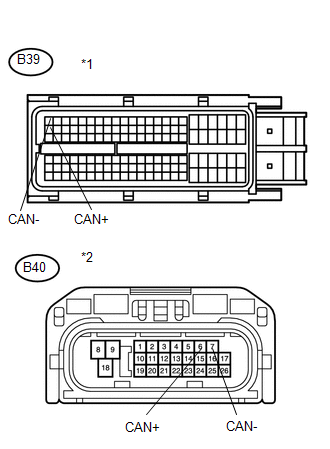

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Perform the universal trip to clear permanent DTCs (See page

.gif) ).

).

HINT:

- Refer to inspection procedure for CAN communication system.

- If the CAN communication malfunctions, the TCM cannot receive the current data from the ECM. In this case, the freeze frame data output from the TCM has not been updated, so the data will not be useful for the inspection. However, reading the Data List as the first step in troubleshooting is effective to find malfunctions.

- The malfunction area can be checked using the Bus Check function on

the Techstream (See page

.gif) ).

).

PROCEDURE

|

1. |

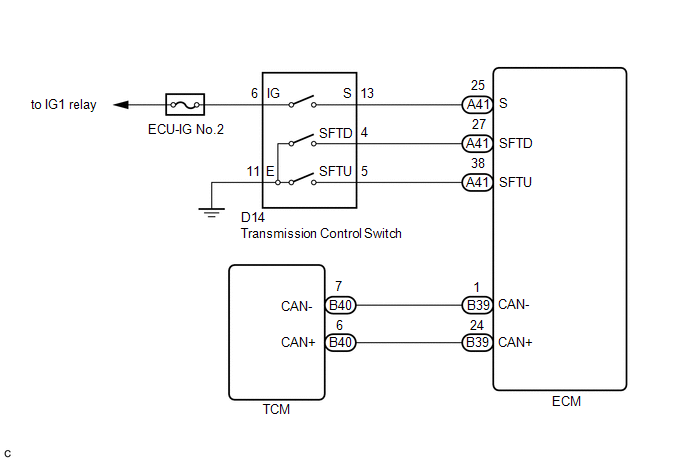

CHECK ECU TERMINAL VOLTAGE (+B AND E1 TERMINALS) |

|

(a) Disconnect the TCM connector. |

|

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

B40-18 (+B) - B40-8 (E1) |

Ignition switch ON |

9 to 14 V |

(d) Turn the ignition switch off.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B40-8 (E1) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to TCM) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

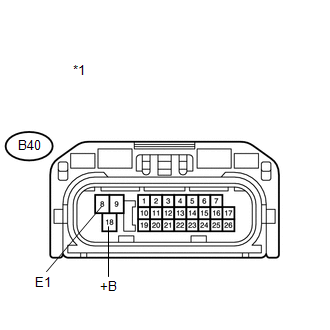

CHECK HARNESS AND CONNECTOR (TCM - ECM) |

|

(a) Disconnect the TCM connector. |

|

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B40-6 (CAN+) - B39-24 (CAN+) |

Always |

Below 1 Ω |

|

B40-7 (CAN-) - B39-1 (CAN-) |

Always |

Below 1 Ω |

|

B40-6 (CAN+) or B39-24 (CAN+) - Body ground or other terminals |

Always |

1 MΩ or higher |

|

B40-7 (CAN-) or B39-1 (CAN-) - Body ground or other terminals |

Always |

1 MΩ or higher |

|

*1 |

Front view of wire harness connector (to ECM) |

|

*2 |

Front view of wire harness connector (to TCM) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK IF DTC OUTPUT RECURS |

(a) Connect the Techstream to the DLC3.

(b) Clear the DTCs.

(c) Replace the TCM.

HINT:

Replace the TCM with a TCM from a normally functioning vehicle of the same model.

(d) Start the engine.

(e) Read the DTCs.

|

Display (DTC Output) |

Proceed to |

|---|---|

|

U0100 |

A |

|

No DTC |

B |

| A | .gif) |

REPLACE ECM |

| B | .gif) |

REPLACE TCM |

Pressure Control Solenoid "G" Electrical (Shift Solenoid Valve SL4) (P2810)

Pressure Control Solenoid "G" Electrical (Shift Solenoid Valve SL4) (P2810)

DESCRIPTION

Changing from 1st to 6th is performed by the TCM turning shift solenoid valves

SL1, SL2, SL3, SL4 and SL on and off. If an open or short circuit occurs in any

of the shift solenoid va ...

Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical

(Shift Solenoid Valve SLU) (P2759)

Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical

(Shift Solenoid Valve SLU) (P2759)

DESCRIPTION

The amount of current flow to the solenoid is controlled by the duty ratio of

the TCM output signal. The higher the duty ratio becomes, the higher the lock-up

hydraulic pressure becom ...

Other materials about Toyota Venza:

Steering Angle Sensor Initialization Incomplete (C1439/31,C1445/31)

DESCRIPTION

The skid control ECU acquires the steering angle sensor zero point every time

the ignition switch is turned to ON and the vehicle is driven at 50 km/h (31 mph)

or more for approximately 30 seconds. The ECU also stores previous zero points.

Wa ...

Transmission Fluid Pressure Sensor / Switch "E" Circuit Low (P0989,P0990)

DESCRIPTION

ATF pressure switch No. 3 is installed in the lock-up solenoid ATF output passage

and is used to detect a malfunction in the lock-up solenoid.

DTC No.

DTC Detection Condition

Trouble Area

P0989

...

Sound Quality is Bad Only when CD is Played (Volume is Too Low)

PROCEDURE

1.

REPLACE CD AND RECHECK

(a) Replace the CD with a known good one and check that the malfunction disappears.

OK:

Malfunction disappears.

OK

END

NG

REPLACE RADIO AN ...

0.14

.gif)