Toyota Venza: Slip Indicator Light Remains ON

DESCRIPTION

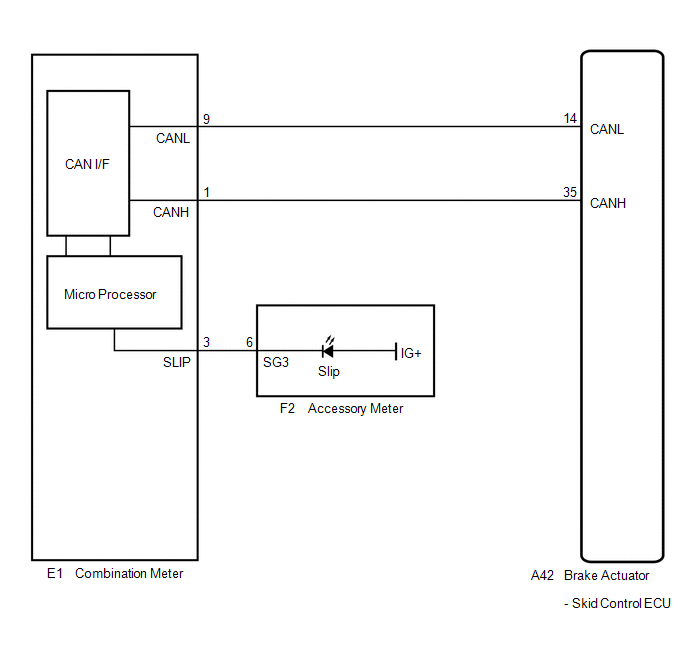

The skid control ECU is connected to the combination meter via CAN communication.

The slip indicator light blinks during VSC and/or TRAC operation.

When the system fails, the slip indicator light comes on to warn the driver (See

page .gif) ).

).

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if a CAN communication system DTC is output (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC is not output |

A |

|

DTC is output |

B |

| B | .gif) |

INSPECT CAN COMMUNICATION SYSTEM |

|

|

2. |

CHECK IF SKID CONTROL ECU CONNECTOR IS SECURELY CONNECTED |

(a) Check if the skid control ECU connector is securely connected.

OK:

The connector is securely connected.

| NG | .gif) |

CONNECT CONNECTOR TO ECU CORRECTLY |

|

|

3. |

CHECK BATTERY |

(a) Check the battery voltage.

Standard voltage:

11 to 14 V

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2GR-FE) |

B |

|

NG (for 1AR-FE) |

C |

| B | .gif) |

CHECK OR REPLACE CHARGING SYSTEM OR BATTERY (for 2GR-FE) |

| C | .gif) |

CHECK OR REPLACE CHARGING SYSTEM OR BATTERY (for 1AR-FE) |

|

|

4. |

INSPECT COMBINATION METER ASSEMBLY |

(a) Turn the ignition switch to ON and check the slip indicator light will come on for approximately 3 seconds (initial check).

(b) Perform the Active Test of the combination meter (meter CPU) using the Techstream

(See page .gif) ).

).

(c) Check the accessory meter.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (Initial check is normal, and the slip indicator light does not turn on or off in accordance with the Techstream operation) |

B |

|

NG (Initial check is abnormal) |

C |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step before replacing the part (See

page .gif) ).

).

| A | .gif) |

REPLACE BRAKE ACTUATOR ASSEMBLY |

| B | .gif) |

REPLACE COMBINATION METER ASSEMBLY |

| C | .gif) |

REPLACE ACCESSORY METER ASSEMBLY |

Slip Indicator Light does not Come ON

Slip Indicator Light does not Come ON

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN communication.

WIRING DIAGRAM

Refer to Slip Indicator Light Remains ON (See page

).

PROCEDURE

1.

...

TC and CG Terminal Circuit

TC and CG Terminal Circuit

DESCRIPTION

Connecting terminals TC and CG of the DLC3 causes the ECU to display the DTC

by blinking the ABS warning and slip indicator lights.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Wh ...

Other materials about Toyota Venza:

Sending Malfunction (Navigation to APGS) (U0073,U0100,U0140,U0155)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the CAN communication circuit.

DTC No.

DTC Detection Condition

Trouble Area

U0073

CAN bus connection error

CAN communicatio ...

Operation Check

OPERATION CHECK

1. NOTICE WHEN CHECKING THE FOLLOWING

(a) Power door lock/unlock function:

This wireless door lock control function operates only when the following 3 conditions

are met:

(1) The engine switch is off.

(2) All doors are closed.

(3) The p ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Sender

Receiver

Signal

Line

Main Body ECU

(Driver Side Junction Block Assembly)

Clearance Warning ECU Assembly

Destination information

...

0.122

.gif)