Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE BOOSTER ASSEMBLY

|

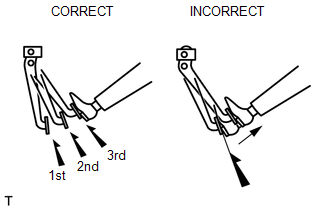

(a) Airtightness check (1) Start the engine and stop it after 1 or 2 minutes. Slowly depress the brake pedal several times. HINT: If the pedal can be depressed to the floor the first time, but on the 2nd and 3rd time cannot be depressed as far, the booster is airtight. (2) Depress the brake pedal while the engine is running, and stop the engine with the pedal depressed. HINT: If there is no change in the pedal reserve distance while holding the pedal depressed for 30 seconds, the booster is airtight. |

|

(b) Operation check

|

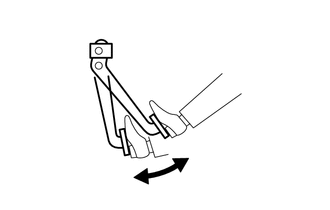

(1) Depress the brake pedal several times with the ignition switch off and check that there is no change in the pedal reserve distance when the pedal is depressed. |

|

|

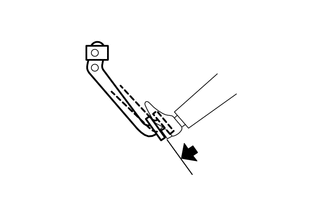

(2) Depress and hold the brake pedal, then start the engine. HINT: If the pedal goes down slightly, operation is normal. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

Release the vacuum from the booster by depressing the brake pedal several times.

Then remove the brake master cylinder from the brake booster.

PROCEDURE

...

Other materials about Toyota Venza:

Cellular Phone Registration Failure

PROCEDURE

1.

CHECK USAGE CONDITION

(a) Check that the vehicle and cellular phone meet the following conditions:

NOTICE:

If changing cellular phone settings, updating software, etc. is necessary, make

sure to obtain the per ...

Sliding Roof ECU Communication Stop (B1273)

DESCRIPTION

This DTC is stored when LIN communication between the sliding roof ECU (sliding

roof drive gear sub-assembly) and main body ECU (driver side junction block assembly)

stops for more than 10 seconds.

DTC No.

DTC Detection ...

Cup holders

► Front

► Rear

Pull down the armrest and open the lid.

- Adjusting size of the front cup holder

Remove the adapter.

CAUTION

- Items unsuitable for the cup holder

Do not place anything other than cups or aluminum cans in the ...

0.1696