Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

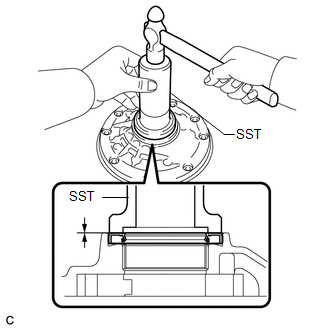

1. INSTALL FRONT OIL PUMP OIL SEAL

|

(a) Using SST and a hammer, install a new oil seal to the oil pump body. SST: 09350-32014 09351-32140 Oil seal driven in depth: -0.25 to 0.25 mm (-0.00984 to 0.00984 in.) |

|

(b) Coat the lip of the oil seal with MP grease.

2. INSTALL FRONT OIL PUMP BODY O-RING

|

(a) Coat a new O-ring with ATF and install it to the oil pump body. NOTICE: Ensure that the O-ring is not twisted. |

|

3. INSTALL FRONT OIL PUMP DRIVEN GEAR

|

(a) Coat the front oil pump driven gear with ATF and install it to the oil pump body with the marked side up. |

|

4. INSTALL FRONT OIL PUMP DRIVE GEAR

|

(a) Coat the front oil pump drive gear with ATF, and install it to the oil pump body with the marked side up. |

|

5. INSTALL STATOR SHAFT ASSEMBLY

|

(a) Align each knock pin of the stator shaft with the holes in the oil pump body and install the stator shaft to the oil pump body. |

|

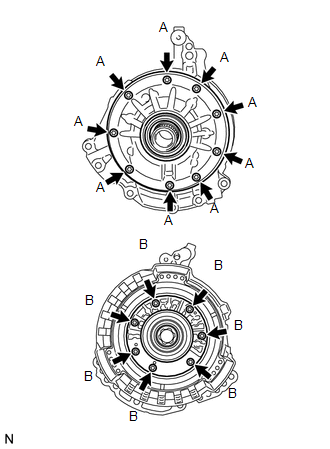

(b) Using a "TORX" socket (T30), install the 16 bolts.

Torque:

9.3 N·m {95 kgf·cm, 82 in·lbf}

| - | Bolt Length |

|---|---|

| Bolt A |

14 mm (0.551 in.) |

| Bolt B |

26 mm (1.02 in.) |

6. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

(a) Turn the drive gear with 2 screwdrivers and make sure that it rotates

smoothly.

NOTICE:

Be careful ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

HOW TO PROCEED WITH TROUBLESHOOTING

1. OPERATION FLOW

HINT:

Perform troubleshooting in accordance with the procedure below. The following

is an outline of basic troubleshooting procedure. Confirm the troubleshooting procedure

for the circuit you are wor ...

Front Left Sensor Malfunction (C1AE1)

DESCRIPTION

The No. 1 ultrasonic sensor (front left sensor) is installed on the front bumper.

The ECU detects obstacles based on signals received from the No. 1 ultrasonic sensor

(front left sensor). If the No. 1 ultrasonic sensor (front left sensor) has ...

Unmatched Encryption Code (B2794)

DESCRIPTION

This DTC is stored when a key with an incomplete key code is inserted into the

ignition key cylinder.

DTC No.

DTC Detection Condition

Trouble Area

B2794

Key with incomplete key code i ...

0.1654

.png)

.png)

.png)