Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

|

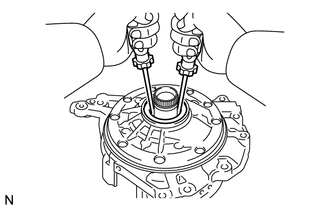

(a) Turn the drive gear with 2 screwdrivers and make sure that it rotates smoothly. NOTICE: Be careful not to damage the oil seal lip. |

|

2. INSPECT CLEARANCE OF FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

|

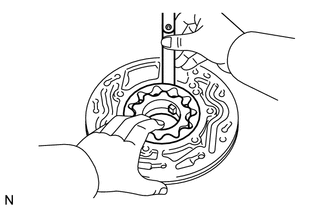

(a) Push the driven gear to one side of the body. |

|

(b) Using a feeler gauge, measure the clearance.

Standard clearance:

0.08 to 0.15 mm (0.00315 to 0.00590 in.)

Maximum clearance:

0.15 mm (0.00590 in.)

If the clearance is greater than the maximum, replace the oil pump body sub-assembly.

|

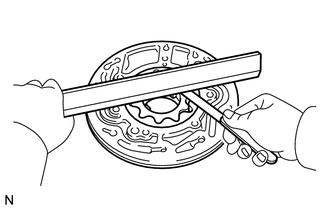

(c) Using a straightedge and feeler gauge, measure the side clearance of both gears. Standard side clearance: 0.025 to 0.04 mm (0.000984 to 0.00157 in.) Maximum side clearance: 0.04 mm (0.00157 in.) Drive Gear Thickness

|

|

3. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

|

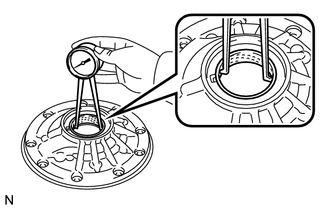

(a) Using a dial indicator, measure the inside diameter of the oil pump body bushing. Standard inside diameter: 43.113 to 43.138 mm (1.6974 to 1.6983 in.) Maximum inside diameter: 43.188 mm (1.7003 in.) If the inside diameter is greater than the maximum, replace the oil pump body sub-assembly. |

|

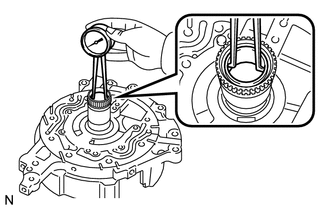

4. INSPECT STATOR SHAFT ASSEMBLY

|

(a) Using a dial indicator, measure the inside diameter of the oil pump body bushing. Standard inside diameter: 22.500 to 22.526 mm (0.8858 to 0.8868 in.) Maximum inside diameter: 22.570 mm (0.8886 in.) If the inside diameter is greater than the maximum, replace the oil pump body sub-assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

2. REMOVE STATOR SHAFT ASSEMBLY

(a) Using a "TORX" wrench (T30), remove the 16 bolts and stator s ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL FRONT OIL PUMP OIL SEAL

(a) Using SST and a hammer, install a new oil seal to the oil pump body.

SST: 09350-32014

09351-32140

Oil seal driven in ...

Other materials about Toyota Venza:

Compressor Solenoid Circuit (B1451/51)

DESCRIPTION

In this circuit, the A/C compressor receives a refrigerant compression demand

signal from the A/C amplifier.

Based on this signal, the A/C compressor changes the amount of compressor output.

DTC No.

DTC Detection Conditio ...

Camshaft Position "B" Actuator Circuit / Open (Bank 1) (P0013)

DESCRIPTION

The Variable Valve Timing (VVT) system adjusts the exhaust valve timing to improve

driveability. The engine oil pressure turns the VVT controller to adjust the valve

timing.

The camshaft timing oil control valve is a solenoid valve and switch ...

Occupant Classification Sensor Power Supply Circuit Malfunction (B1793)

DESCRIPTION

The occupant classification sensor power supply circuit consists of the occupant

classification ECU and occupant classification sensors.

DTC B1793 is recorded when a malfunction is detected in the occupant classification

sensor power supply c ...

0.1525