Toyota Venza: Rear Speed Sensor RH Circuit (C0210/33,C0215/34,C1273/73,C1274/74,C1332/38,C1333/39)

DESCRIPTION

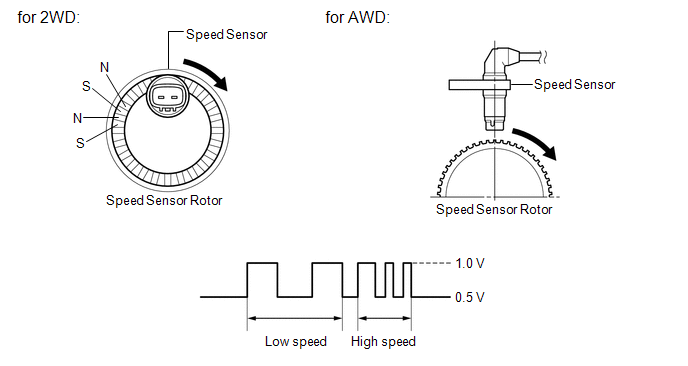

The speed sensor detects the wheel speed and sends the appropriate signals to the skid control ECU. These signals are used for the ABS control system.

Speed sensor rotors have rows of alternating N and S magnetic poles (for 2WD) or 48 serrations (for AWD). The hall IC type speed sensor use the frequency of output pulses to detect the vehicle speed. Because the sensor outputs digital pulses, it can detect vehicle speeds even when the vehicle is nearly stationary.

DTCs C1273/73 and C1274/74 will be cleared when the speed sensor sends a vehicle speed signal or when Test Mode ends. DTCs C1273/73 and C1274/74 are output only in Test Mode.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C0210/33 C0215/34 |

Any of the following is detected:

|

|

|

C1332/38 C1333/39 |

An open or short in the speed sensor signal circuit. |

|

|

C1273/73 C1274/74 |

Detected only during Test Mode. |

|

HINT:

- DTCs C0210/33, C1273/73 and C1332/38 are for the rear speed sensor RH.

- DTCs C0215/34, C1274/74 and C1333/39 are for the rear speed sensor LH.

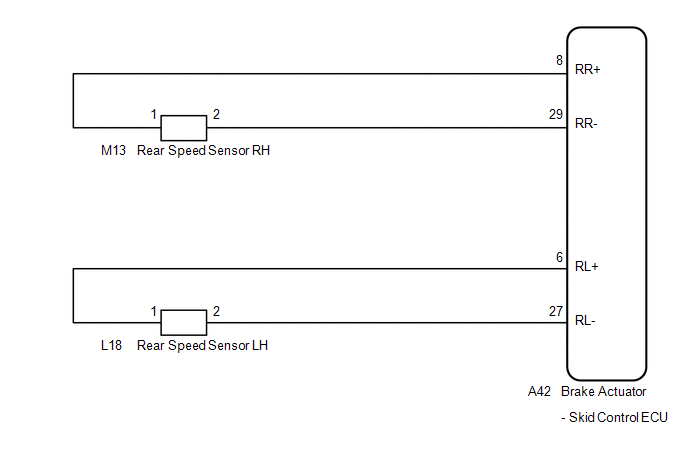

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (REAR SPEED SENSOR) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Select the Data List on the Techstream (See page

.gif) ).

).

ABS/VSC/TRAC

|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

RR Wheel Speed |

Rear wheel speed sensor RH reading / Min.: 0 km/h (0 mph), Max.: 326 km/h (202 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations |

|

RL Wheel Speed |

Rear wheel speed sensor LH reading / Min.: 0 km/h (0 mph), Max.: 326 km/h (202 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations |

(d) Check that the speed value output from the speed sensor displayed on the Techstream.

HINT:

Factors that affect the indicated vehicle speed include tire size, tire inflation,

and tire wear. The speed indicated on the speedometer has an allowable margin of

error. This can be tested using a speedometer tester (calibrated chassis dynamometer).

For details about testing and the margin of error, see the reference chart (See

page .gif) ).

).

OK:

The speed value output from the speed sensor displayed on the Techstream is the similar speed as indicated on the speedometer.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2WD) |

B |

|

NG (for AWD) |

C |

| B | .gif) |

GO TO STEP 4 |

| C | .gif) |

GO TO STEP 10 |

|

|

2. |

PERFORM TEST MODE INSPECTION (SIGNAL CHECK) |

(a) Turn the ignition switch off.

(b) Perform sensor check in Test Mode Procedure (See page

.gif) ).

).

OK:

All Test Mode DTCs are not output.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (for 2WD) |

B |

|

NG (for AWD) |

C |

| B | .gif) |

GO TO STEP 4 |

| C | .gif) |

GO TO STEP 10 |

|

|

3. |

RECONFIRM DTC |

(a) Turn the ignition switch off.

(b) Clear the DTCs (See page .gif) ).

).

(c) Start the engine.

(d) Drive the vehicle at a speed of 45 km/h (28 mph) or more for at least 60 seconds.

(e) Check if the same DTC is recorded (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTCs (C0210/33, C0215/34, C1332/38 and C1333/39) are not output |

A |

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output (for 2WD) |

B |

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output (for AWD) |

C |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step (See page

.gif) ).

).

| A | .gif) |

CHECK FOR INTERMITTENT PROBLEMS |

| B | .gif) |

GO TO STEP 8 |

| C | .gif) |

GO TO STEP 14 |

|

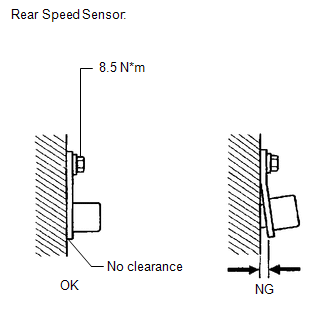

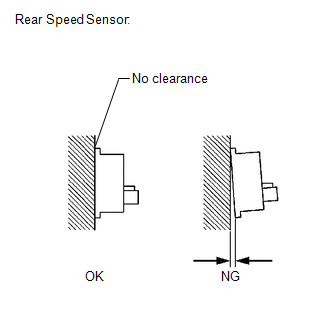

4. |

CHECK REAR SPEED SENSOR INSTALLATION |

|

(a) Turn the ignition switch off. |

|

(b) Check the speed sensor installation.

OK:

There is no clearance between the sensor and rear axle carrier.

| NG | .gif) |

INSTALL REAR SPEED SENSOR CORRECTLY |

|

|

5. |

CHECK HARNESS AND CONNECTOR (SKID CONTROL SENSOR WIRE) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. |

|

(b) Disconnect the skid control sensor wire.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for RH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M13 ("A"-2) - M13 ("B"-1) |

Always |

Below 1 Ω |

|

M13 ("A"-2) - M13 ("B"-2) |

Always |

10 kΩ or higher |

|

M13 ("A"-2) - Body ground |

Always |

10 kΩ or higher |

|

M13 ("A"-1) - M13 ("B"-2) |

Always |

Below 1 Ω |

|

M13 ("A"-1) - M13 ("B"-1) |

Always |

10 kΩ or higher |

|

M13 ("A"-1) - Body ground |

Always |

10 kΩ or higher |

for LH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

L18 ("A"-2) - L18 ("B"-1) |

Always |

Below 1 Ω |

|

L18 ("A"-2) - L18 ("B"-2) |

Always |

10 kΩ or higher |

|

L18 ("A"-2) - Body ground |

Always |

10 kΩ or higher |

|

L18 ("A"-1) - L18 ("B"-2) |

Always |

Below 1 Ω |

|

L18 ("A"-1) - L18 ("B"-1) |

Always |

10 kΩ or higher |

|

L18 ("A"-1) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of skid control sensor wire |

|

*2 |

for RH |

|

*3 |

for LH |

|

*4 |

Front view of wire harness connector (to Sensor Side Connector "A") |

|

*5 |

Front view of wire harness connector (to Vehicle Side Connector "B") |

NOTICE:

Check the speed sensor signal after replacement (See page

.gif) ).

).

| NG | .gif) |

REPLACE SKID CONTROL SENSOR WIRE |

|

|

6. |

CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - REAR SPEED SENSOR) |

|

(a) Reconnect the skid control sensor wire. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

(c) Disconnect the skid control ECU connector and the rear speed sensor connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for RH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-8 (RR+) - M13-1 (RR+) |

Always |

Below 1 Ω |

|

A42-8 (RR+) - Body ground |

Always |

10 kΩ or higher |

|

A42-29 (RR-) - M13-2 (RR-) |

Always |

Below 1 Ω |

|

A42-29 (RR-) - Body ground |

Always |

10 kΩ or higher |

for LH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-6 (RL+) - L18-1 (RL+) |

Always |

Below 1 Ω |

|

A42-6 (RL+) - Body ground |

Always |

10 kΩ or higher |

|

A42-27 (RL-) - L18-2 (RL-) |

Always |

Below 1 Ω |

|

A42-27 (RL-) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Brake Actuator (Skid Control ECU)) |

|

*2 |

Front view of wire harness connector (to Rear Speed Sensor) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

RECONFIRM DTC |

(a) Reconnect the skid control ECU connector and the rear speed sensor connector.

(b) Clear the DTCs (See page .gif) ).

).

(c) Start the engine.

(d) Drive the vehicle at a speed of 45 km/h (28 mph) or more for at least 60 seconds.

(e) Check if the same DTC is recorded (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output |

A |

|

DTCs (C0210/33, C0215/34, C1332/38 and C1333/39) are not output |

B |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step (See page

.gif) ).

).

| B | .gif) |

CHECK FOR INTERMITTENT PROBLEMS |

|

|

8. |

REPLACE REAR SPEED SENSOR AND REAR SPEED SENSOR ROTOR |

(a) Turn the ignition switch off.

(b) Replace the rear speed sensor and the rear axle hub and bearing assembly

(rear speed sensor rotor) (See page .gif) ).

).

HINT:

The rear speed sensor rotor is incorporated into the rear axle hub and bearing assembly.

If the rear speed sensor rotor needs to be replaced, replace it together with the rear axle hub and bearing assembly with the rear speed sensor.

NOTICE:

Check the speed sensor signal after replacement (See page

.gif) ).

).

|

|

9. |

RECONFIRM DTC |

(a) Clear the DTCs (See page .gif) ).

).

(b) Start the engine.

(c) Drive the vehicle at a speed of 45 km/h (28 mph) or more for at least 60 seconds.

(d) Check if the same DTC is recorded (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTCs (C0210/33, C0215/34, C1332/38 and C1333/39) are not output |

A |

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output |

B |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step (See page

.gif) ).

).

| A | .gif) |

END |

| B | .gif) |

REPLACE BRAKE ACTUATOR ASSEMBLY |

|

10. |

CHECK REAR SPEED SENSOR INSTALLATION |

|

(a) Turn the ignition switch off. |

|

(b) Check the speed sensor installation.

OK:

There is no clearance between the sensor and the rear axle carrier.

The installation bolt is tightened properly.

Torque

8.5 N*m (87 kgf*cm, 75 in.*lbf)

| NG | .gif) |

INSTALL REAR SPEED SENSOR CORRECTLY |

|

|

11. |

CHECK REAR SPEED SENSOR TIP |

(a) Remove the rear speed sensor (See page .gif)

).

(b) Check the speed sensor tip.

OK:

No scratches, oil, or foreign matter on the sensor tip.

NOTICE:

Check the speed sensor signal after cleaning or replacement (See page

.gif) ).

).

| NG | .gif) |

CLEAN OR REPLACE REAR SPEED SENSOR |

|

|

12. |

CHECK HARNESS AND CONNECTOR (SKID CONTROL ECU - REAR SPEED SENSOR) |

|

(a) Install the rear speed sensor. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

(c) Disconnect the skid control ECU connector and the rear speed sensor connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for RH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-8 (RR+) - M13-1 (RR+) |

Always |

Below 1 Ω |

|

A42-8 (RR+) - Body ground |

Always |

10 kΩ or higher |

|

A42-29 (RR-) - M13-2 (RR-) |

Always |

Below 1 Ω |

|

A42-29 (RR-) - Body ground |

Always |

10 kΩ or higher |

for LH

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A42-6 (RL+) - L18-1 (RL+) |

Always |

Below 1 Ω |

|

A42-6 (RL+) - Body ground |

Always |

10 kΩ or higher |

|

A42-27 (RL-) - L18-2 (RL-) |

Always |

Below 1 Ω |

|

A42-27 (RL-) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Brake Actuator (Skid Control ECU)) |

|

*2 |

Front view of wire harness connector (to Rear Speed Sensor) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

13. |

RECONFIRM DTC |

(a) Reconnect the skid control ECU connector and the rear speed sensor connector.

(b) Clear the DTCs (See page .gif) ).

).

(c) Start the engine.

(d) Drive the vehicle at a speed of 45 km/h (28 mph) or more for at least 60 seconds.

(e) Check if the same DTC is recorded (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output |

A |

|

DTCs (C0210/33, C0215/34, C1332/38 and C1333/39) are not output |

B |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step (See page

.gif) ).

).

| B | .gif) |

CHECK FOR INTERMITTENT PROBLEMS |

|

|

14. |

REPLACE REAR SPEED SENSOR |

(a) Turn the ignition switch off.

(b) Replace the rear speed sensor (See page .gif)

).

NOTICE:

Check the speed sensor signal after replacement (See page

.gif) ).

).

|

|

15. |

RECONFIRM DTC |

(a) Clear the DTCs (See page .gif) ).

).

(b) Start the engine.

(c) Drive the vehicle at a speed of 45 km/h (28 mph) or more for at least 60 seconds.

(d) Check if the same DTC is recorded (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output |

A |

|

DTCs (C0210/33, C0215/34, C1332/38 and C1333/39) are not output |

B |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step (See page

.gif) ).

).

| B | .gif) |

END |

|

|

16. |

REPLACE REAR SPEED SENSOR ROTOR |

(a) Turn the ignition switch off.

(b) Remove the rear drive shaft assembly (See page

.gif) ).

).

(c) Replace the rear drive outboard joint shaft assembly (rear speed sensor rotor)

(See page .gif) ).

).

HINT:

If the rear speed sensor rotor needs to be replaced, replace it together with the rear drive outboard joint shaft assembly.

NOTICE:

Check the speed sensor signal after replacement (See page

.gif) ).

).

|

|

17. |

RECONFIRM DTC |

(a) Install the rear drive shaft assembly.

(b) Clear the DTCs (See page .gif) ).

).

(c) Start the engine.

(d) Drive the vehicle at a speed of 45 km/h (28 mph) or more for at least 60 seconds.

(e) Check if the same DTC is recorded (See page

.gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTCs (C0210/33, C0215/34, C1332/38 and C1333/39) are not output |

A |

|

DTCs (C0210/33, C0215/34, C1332/38 and/or C1333/39) are output |

B |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table,

refer back to the table and proceed to the next step (See page

.gif) ).

).

| A | .gif) |

END |

| B | .gif) |

REPLACE BRAKE ACTUATOR ASSEMBLY |

ABS Control System Malfunction (43)

ABS Control System Malfunction (43)

DESCRIPTION

This DTC is output when the VSC system detects a malfunction in the ABS control

system.

DTC Code

DTC Detection Condition

Trouble Area

...

Front Speed Sensor RH Circuit (C0200/31,C0205/32,C1271/71,C1272/72,C1330/35,C1331/36)

Front Speed Sensor RH Circuit (C0200/31,C0205/32,C1271/71,C1272/72,C1330/35,C1331/36)

DESCRIPTION

The speed sensor detects wheel speed and sends the appropriate signals to the

skid control ECU. These signals are used for the ABS control system.

Speed sensor rotors have 48 serration ...

Other materials about Toyota Venza:

Power Back Door Main Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT POWER BACK DOOR MAIN SWITCH

(a) Check that the switch function.

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

...

Fail-safe Chart

FAIL-SAFE CHART

1. POWER WINDOW OPERATION IN FAIL-SAFE MODE

HINT:

If the pulse sensor built into the power window regulator motor malfunctions,

the power window control system enters fail-safe mode.

(a) The power window control system prohibits the follo ...

Front Stabilizer Bar(for 2gr-fe 2wd)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT FRAME ASSEMBLY (When Using the Engine Support Bridge)

(See page )

2. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE (When Not Using the Engine Support Bridge)

(See page )

3. ...

0.1605

.gif)

.png)

.png)