Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

.gif)

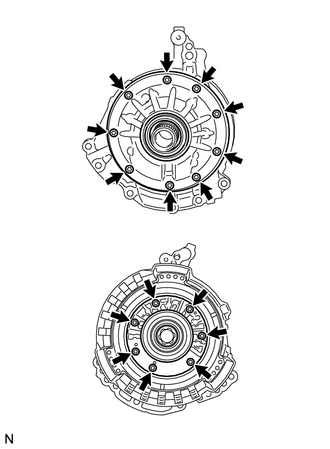

2. REMOVE STATOR SHAFT ASSEMBLY

|

(a) Using a "TORX" wrench (T30), remove the 16 bolts and stator shaft assembly from the oil pump body. NOTICE: Keep the gears in the order of disassembly. |

|

3. INSPECT CLEARANCE OF FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

.gif)

4. REMOVE FRONT OIL PUMP BODY O-RING

|

(a) Remove the O-ring from the oil pump body. |

|

5. REMOVE FRONT OIL PUMP DRIVE GEAR

|

(a) Remove the front oil pump drive gear from the oil pump body. |

|

6. REMOVE FRONT OIL PUMP DRIVEN GEAR

|

(a) Remove the front oil pump driven gear from the oil pump body. |

|

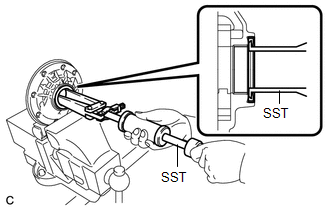

7. REMOVE FRONT OIL PUMP OIL SEAL

|

(a) Mount the oil pump in a soft jaw vise. |

|

(b) Using SST, remove the oil seal from the oil pump body.

SST: 09308-00010

Components

Components

COMPONENTS

ILLUSTRATION

...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

(a) Turn the drive gear with 2 screwdrivers and make sure that it rotates

smoothly.

NOTICE:

Be careful ...

Other materials about Toyota Venza:

Noise Occurs

PROCEDURE

1.

CHECK NOISE CONDITION

(a) Check from which direction the noise comes (front left or right, or rear

left or right).

OK:

The location of the noise source can be determined.

NG

GO TO STEP 3

...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

NOTICE:

Turn the ignition switch off before removing any parts.

HINT:

If no malfunction is found when inspecting parts, inspect the skid control

ECU and ground points for poor connections.

If a trouble code is ...

Operation Check

OPERATION CHECK

1. CHECK POWER SEAT FUNCTION

(a) Check the basic functions.

(1) Operate the power seat switches and check to make sure each seat function

work:

Sliding

Front vertical (Driver side only)

Lumbar support

Lifter (Driver s ...

0.1147