Toyota Venza: Fuel Injector Circuit

DESCRIPTION

The fuel injector assemblies are located on the intake manifold. They inject fuel into the cylinders based on signals from the ECM.

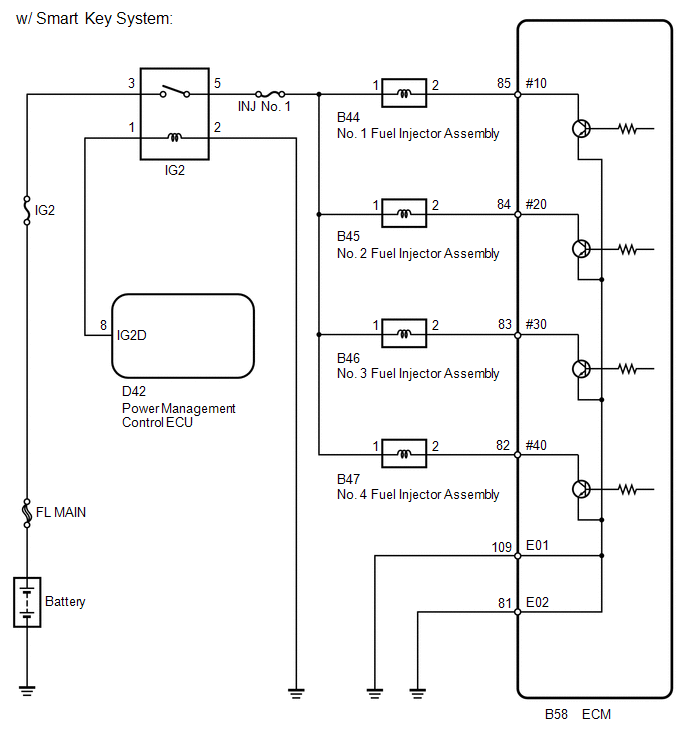

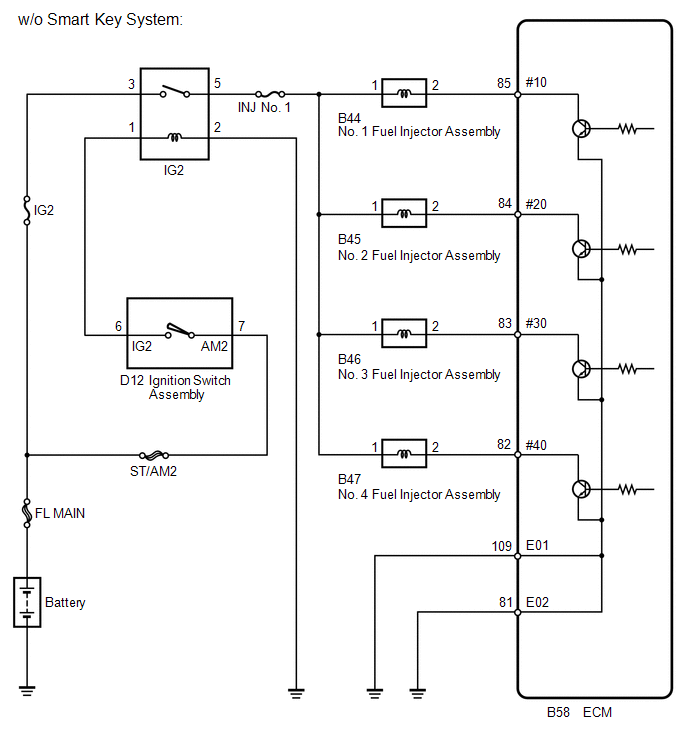

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK FUEL INJECTOR ASSEMBLY (POWER SOURCE) |

|

(a) Disconnect the fuel injector assembly connector. |

|

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

B44-1 - Body ground |

Ignition switch ON |

11 to 14 V |

|

B45-1 - Body ground |

Ignition switch ON |

11 to 14 V |

|

B46-1 - Body ground |

Ignition switch ON |

11 to 14 V |

|

B47-1 - Body ground |

Ignition switch ON |

11 to 14 V |

|

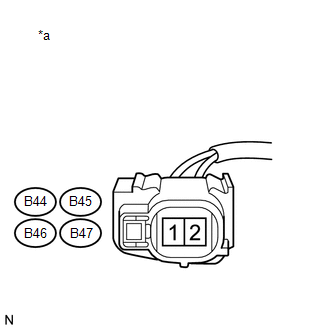

*a |

Front view of wire harness connector (to Fuel Injector Assembly) |

| NG | .gif) |

GO TO STEP 4 |

|

|

2. |

INSPECT FUEL INJECTOR ASSEMBLY |

(a) Inspect the fuel injector assembly (See page

.gif) ).

).

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly

(See page .gif) ).

).

| NG | .gif) |

REPLACE FUEL INJECTOR ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (FUEL INJECTOR ASSEMBLY - ECM) |

(a) Disconnect the fuel injector assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B44-2 - B58-85 (#10) |

Always |

Below 1 Ω |

|

B45-2 - B58-84 (#20) |

Always |

Below 1 Ω |

|

B46-2 - B58-83 (#30) |

Always |

Below 1 Ω |

|

B47-2 - B58-82 (#40) |

Always |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B44-2 or B58-85 (#10) - Body ground |

Always |

10 kΩ or higher |

|

B45-2 or B58-84 (#20) - Body ground |

Always |

10 kΩ or higher |

|

B46-2 or B58-83 (#30) - Body ground |

Always |

10 kΩ or higher |

|

B47-2 or B58-82 (#40) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (FUEL INJECTOR ASSEMBLY - ECM) |

|

4. |

CHECK HARNESS AND CONNECTOR (IG2 RELAY - FUEL INJECTOR ASSEMBLY) |

(a) Disconnect the fuel injector assembly connector.

(b) Remove the IG2 relay from the engine room relay block.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B44-1 - 5 (IG2 relay terminal) |

Always |

Below 1 Ω |

|

B45-1 - 5 (IG2 relay terminal) |

Always |

Below 1 Ω |

|

B46-1 - 5 (IG2 relay terminal) |

Always |

Below 1 Ω |

|

B47-1 - 5 (IG2 relay terminal) |

Always |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B44-1 or 5 (IG2 relay terminal) - Body ground |

Always |

10 kΩ or higher |

|

B45-1 or 5 (IG2 relay terminal) - Body ground |

Always |

10 kΩ or higher |

|

B46-1 or 5 (IG2 relay terminal) - Body ground |

Always |

10 kΩ or higher |

|

B47-1 or 5 (IG2 relay terminal) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

CHECK ECM POWER SOURCE CIRCUIT |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (IG2 RELAY - FUEL INJECTOR ASSEMBLY) |

Fuel Pump Control Circuit

Fuel Pump Control Circuit

DESCRIPTION

1. w/o Smart Key System

When the engine is cranked, the starter relay drive signal output from the ignition

switch is input into the STA terminal of the ECM, and the NE signal generate ...

ACIS Control Circuit

ACIS Control Circuit

DESCRIPTION

This circuit opens and closes the Intake Air Control Valve (IACV) in response

to the engine load in order to increase the intake efficiency (ACIS: Acoustic Control

Induction System).

...

Other materials about Toyota Venza:

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE PROPELLER SHAFT

(a) Place matchmarks on both flanges.

Text in Illustration

*1

Matchmark

(b) Remove the 4 nuts, ...

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the cable from the negative (-)

bat ...

Back Door Entry Lock Function does not Operate

DESCRIPTION

If the back door entry lock function does not operate but the back door open

function operates, the communication between the vehicle and key is normal. As a

faulty part, the entry lock switch circuit (from the back door opener switch assembly ...

0.1607

.gif)