Toyota Venza: Back Door Entry Lock Function does not Operate

DESCRIPTION

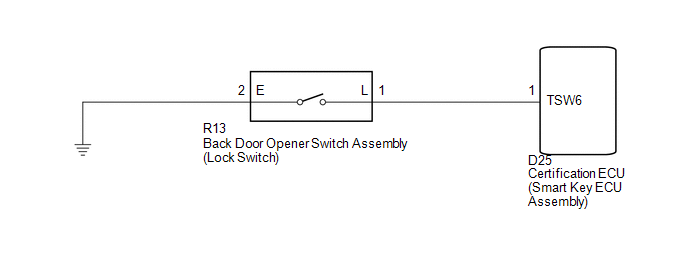

If the back door entry lock function does not operate but the back door open function operates, the communication between the vehicle and key is normal. As a faulty part, the entry lock switch circuit (from the back door opener switch assembly (lock switch) to the certification ECU (smart key ECU assembly)) is suspected.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- The smart key system (for entry function) uses a multiplex communication

system (LIN communication system) and CAN communication system. Inspect

the communication function by following How to Proceed with Troubleshooting

(See page

.gif) ). Troubleshoot the smart

). Troubleshoot the smart

key system (for entry function) after confirming that the communication system is functioning properly. - Confirm that another key is not in the cabin.

PROCEDURE

|

1. |

CHECK POWER DOOR LOCK OPERATION |

(a) When the door control switch on the master switch assembly is operated, check

that the doors unlock and lock according to switch operation (See page

.gif) ).

).

OK:

Door locks operate normally.

| NG | .gif) |

GO TO POWER DOOR LOCK CONTROL SYSTEM (Proceed to Problem Symptoms Table) |

|

|

2. |

READ VALUE USING TECHSTREAM (BACK DOOR OPENER SWITCH) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Data List.

(e) Read the Data List according to the display on the Techstream.

Smart Key (Certification ECU (Smart Key ECU Assembly))|

Tester Display |

Measurement Item/Display |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Tr/B-Door Lock SW |

Back door opener switch assembly (lock switch) / ON or OFF |

ON: Back door opener switch assembly (lock switch) pushed OFF: Back door opener switch assembly (lock switch) not pushed |

- |

OK:

On the Techstream screen, the display changes between ON and OFF as shown in the chart above.

| OK | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

|

3. |

INSPECT BACK DOOR OPENER SWITCH ASSEMBLY |

|

(a) Remove the back door opener switch assembly (See page

|

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Position |

Specified Condition |

|---|---|---|

|

1 (L) - 2 (E) |

Back door opener switch assembly (lock switch) not pushed (OFF) |

10 kΩ or higher |

|

1 (L) - 2 (E) |

Back door opener switch assembly (lock switch) pushed (ON) |

Below 1 Ω |

|

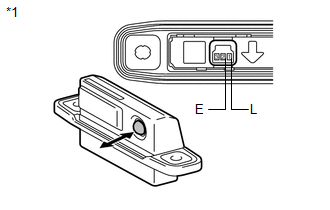

*1 |

Component without harness connected (Back Door Opener Switch Assembly) |

| NG | .gif) |

REPLACE BACK DOOR OPENER SWITCH ASSEMBLY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU - BACK DOOR OPENER SWITCH) |

|

(a) Disconnect the certification ECU (smart key ECU assembly) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D25-1 (TSW6) - R13-1 (L) |

Always |

Below 1 Ω |

|

D25-1 (TSW6) - Body ground |

Always |

10 kΩ or higher |

|

R13-1 (L) - Body ground |

Always |

10 kΩ or higher |

|

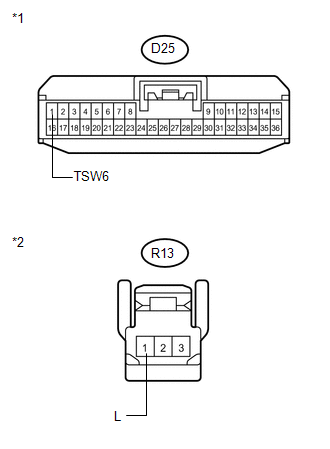

*1 |

Front view of wire harness connector (to Certification ECU (Smart Key ECU Assembly)) |

|

*2 |

Front view of wire harness connector (to Back Door Opener Switch Assembly) |

| OK | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Back Door Entry Lock and Unlock Functions do not Operate

Back Door Entry Lock and Unlock Functions do not Operate

DESCRIPTION

When the back door entry lock and unlock functions do not operate, one of the

following may be malfunctioning: 1) power door lock control system; 2) outside electrical

key oscillator ...

Other materials about Toyota Venza:

Multi-information display (LCD type)

The multi-information display presents the driver with a variety of driving-related

data, including the clock and current outside temperature.

• Clock

Indicates and sets the time.

• Outside temperature

Indicates the outside temperature.

The temper ...

ECM Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

ECM Communication Stop Mode

"Engine" and "ECT" are not displayed on "CAN Bus Check" screen

of the Techs ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DOOR BELT MOULDING

(a) Engage the 5 claws to install the front door belt moulding.

(b) Install the clip.

2. INSTALL FRONT DOOR GLASS RUN

3. INSTALL FRONT ...

0.161

.gif)