Toyota Venza: Steering Lock Motor Drive Power Circuit

DESCRIPTION

The steering lock ECU (steering lock actuator assembly) is connected to the power management control ECU. The steering lock ECU (steering lock actuator assembly) cannot activate the motor unless it receives permission signals from both ECUs. (The power management control ECU permits the steering lock ECU (steering lock actuator assembly) to supply power to activate the motor.)

WIRING DIAGRAM

.png)

PROCEDURE

|

1. |

CHECK VEHICLE CONDITION |

(a) Check the problem symptom of the steering lock system.

|

Condition |

Proceed to |

|---|---|

|

Steering lock cannot be released. |

A |

|

Steering cannot be locked. |

B |

| B | .gif) |

GO TO STEP 6 |

|

|

2. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Check the steering lock command reception record. Enter the following menus: Body Electrical / Smart Key / Data List.

Smart Key|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Lock/Unlock Receive |

Steering lock command reception record / Yes or No |

Yes: Steering lock/unlock signal received No: Steering lock/unlock signal not received |

- |

(e) Check if steering unlock command reception is confirmed.

OK:

"YES" is displayed on the Techstream.

| NG | .gif) |

CHECK SMART KEY SYSTEM (for Start Function) |

|

|

3. |

INSPECT STEERING LOCK ECU (STEERING LOCK ACTUATOR ASSEMBLY) |

|

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

|

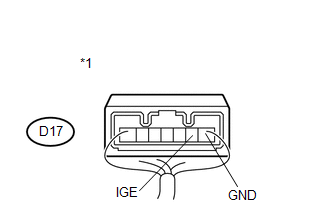

*1 |

Component with harness connected (Steering Lock ECU (Steering Lock Actuator Assembly)) |

| OK | .gif) |

PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

4. |

CHECK HARNESS AND CONNECTOR (STEERING LOCK ECU - BODY GROUND) |

|

(a) Disconnect the D17 connector from the steering lock ECU (steering lock actuator assembly). |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D17-1 (GND) - Body ground |

Always |

Below 1 Ω |

|

*1 |

Front view of wire harness connector (to Steering Lock ECU (Steering Lock Actuator Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (STEERING LOCK ECU - POWER MANAGEMENT CONTROL ECU) |

|

(a) Disconnect the D43 connector from the power management control ECU. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D17-3 (IGE) - D43-8 (SLR+) |

Always |

Below 1 Ω |

|

D17-3 (IGE) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Steering Lock ECU (Steering Lock Actuator Assembly)) |

|

*2 |

Front view of wire harness connector (to Power Management Control ECU) |

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

6. |

INSPECT STEERING LOCK ECU (STEERING LOCK ACTUATOR ASSEMBLY) |

|

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

|

*1 |

Component with harness connected (Steering Lock ECU (Steering Lock Actuator Assembly)) |

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

7. |

CHECK HARNESS AND CONNECTOR (STEERING LOCK ECU - POWER MANAGEMENT CONTROL ECU) |

|

(a) Disconnect the D17 connector from the steering lock ECU (steering lock actuator assembly). |

|

(b) Disconnect the D43 connector from the power management control ECU.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D17-3 (IGE) - D43-8 (SLR+) |

Always |

Below 1 Ω |

|

D17-3 (IGE) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Steering Lock ECU (Steering Lock Actuator Assembly)) |

|

*2 |

Front view of wire harness connector (to Power Management Control ECU) |

| OK | .gif) |

REPLACE POWER MANAGEMENT CONTROL ECU |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Open / Short in Steering Lock ECU (B2781)

Open / Short in Steering Lock ECU (B2781)

DESCRIPTION

If the steering lock ECU (steering lock actuator assembly) determines that there

is a malfunction inside the ECU, it outputs this DTC. Diagnostic communication between

the steering lo ...

Unlock Position Sensor Signal Circuit

Unlock Position Sensor Signal Circuit

DESCRIPTION

The unlock position sensor is one of the components comprising the steering lock

ECU (steering lock actuator assembly). The sensor switch contact closes when the

steering lock is rele ...

Other materials about Toyota Venza:

Removal

REMOVAL

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

).

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting

the cable from the negative (-) battery term ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT SOLENOID VALVE SL4

(a) Coat the shift solenoid valve SL4 and bolt with ATF.

Text in Illustration

*1

Lock Plate

*2

Solenoid V ...

0.1771

.gif)

.png)

.png)

.png)