Toyota Venza: Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

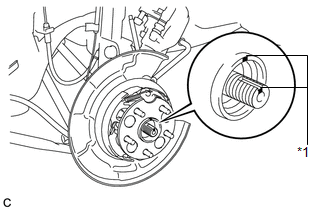

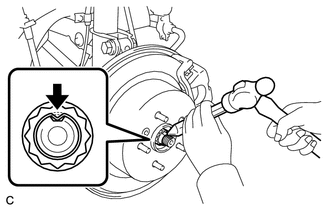

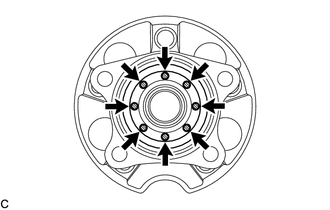

1. INSTALL REAR AXLE HUB AND BEARING ASSEMBLY

(a) Apply a total of 0.1 to 0.3g (0.00353 to 0.0105 oz.) of Toyota Body Grease W to the 8 areas shown in the illustration.

Text in Illustration

Text in Illustration

.png) |

Toyota Body Grease W |

|

(b) Align the matchmarks on the rear drive shaft assembly and the rear axle hub and bearing assembly. Text in Illustration

NOTICE: Do not rotate the rear drive shaft. |

|

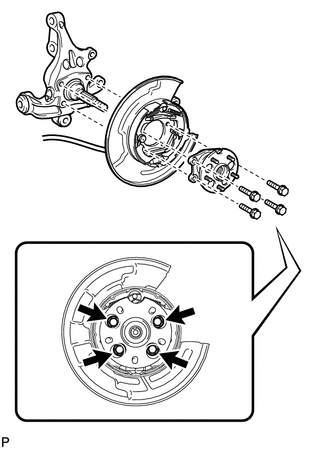

|

(c) Install the parking brake assembly and the rear axle hub and bearing assembly with the 4 bolts. Torque: 80 N·m {816 kgf·cm, 59 ft·lbf} NOTICE: Do not twist the parking brake cable assembly when installing it. |

|

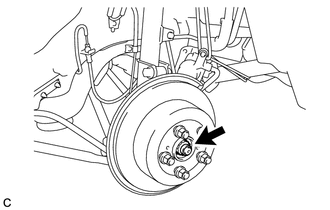

2. INSTALL REAR AXLE SHAFT NUT

|

(a) Clean the threaded parts on the rear drive shaft assembly and a new rear axle shaft nut using a non-residue solvent. NOTICE:

|

|

(b) install the rear disc with the 5 hub nuts.

(c) While applying the parking brakes, temporarily install the new rear axle shaft nut.

Torque:

294 N·m {2998 kgf·cm, 217 ft·lbf}

NOTICE:

Stake the nut after inspecting for looseness and runout in the following steps.

(d) Remove the 5 hub nuts and the rear disc.

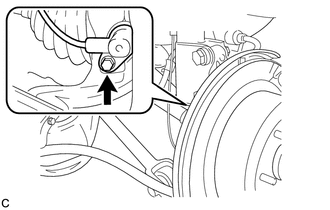

3. INSTALL REAR SPEED SENSOR

|

(a) Install the rear speed sensor to the rear axle carrier sub-assembly with the bolt. Torque: 8.5 N·m {87 kgf·cm, 75 in·lbf} NOTICE:

|

|

4. INSPECT REAR AXLE HUB BEARING LOOSENESS

.gif)

5. INSPECT REAR AXLE HUB RUNOUT

.gif)

6. INSTALL REAR DISC

.gif)

7. INSTALL REAR DISC BRAKE CALIPER ASSEMBLY

.gif)

8. STAKE REAR AXLE SHAFT NUT

|

(a) Using a chisel and a hammer, stake the rear axle shaft nut. |

|

9. INSTALL REAR WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

10. CHECK FOR SPEED SENSOR SIGNAL

(a) Check for the speed sensor signal (See page

.gif) ).

).

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR W ...

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPAR ...

Other materials about Toyota Venza:

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR SEAT LEG ASSEMBLY RH

(a) Using a T55 "TORX" socket wrench, install the rear seat leg assembly

RH with the 5 "TORX" bolts.

Torque:

A :

42 N·m {428 kgf·cm, 31 ft·lbf}

B : ...

Outer Rear View Mirror Cover

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL OUTER MIRROR COVER

(a) Engage the 7 claws to install the outer mirror cover.

2. INSTALL OUTER MIRROR

R ...

Air Conditioning Amplifier Communication Stop Mode

DESCRIPTION

Detection Item

Symptom

Trouble Area

Air Conditioning Amplifier Communication Stop Mode

"Air Conditioner" is not displayed on "CAN Bus Check" screen

o ...

0.1559