Toyota Venza: Security Horn Circuit

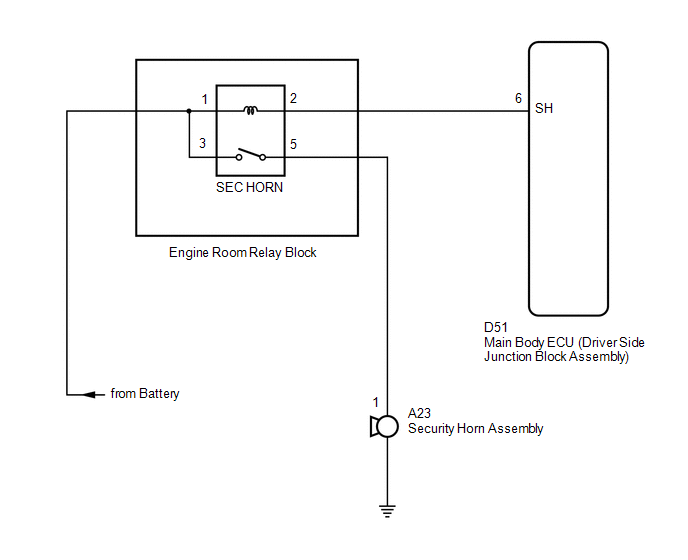

DESCRIPTION

When the theft deterrent system is switched from the armed state to the alarm sounding state, the main body ECU (driver side junction block assembly) controls the security horn.

WIRING DIAGRAM

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Select the item below in the Active Test and then check that the security horn assembly operates.

Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Security Horn |

Security horn |

ON/OFF |

- |

OK:

The security horn assembly sounds and stops correctly when operated through the Techstream.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

INSPECT SECURITY HORN ASSEMBLY |

|

(a) Remove the security horn assembly (See page

|

|

(b) Check the operation of the security horn assembly.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 1 |

Horn sounds |

|

Battery negative (-) → Horn body |

| NG | .gif) |

REPLACE SECURITY HORN ASSEMBLY |

|

|

3. |

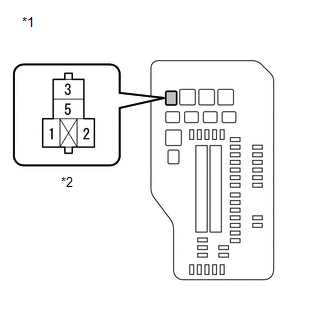

INSPECT SEC HORN RELAY |

|

(a) Remove the SEC HORN relay from the engine room relay block. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 - 5 |

Battery voltage applied to terminals 1 and 2 |

Below 1 Ω |

|

3 - 5 |

Battery voltage not applied between terminals 1 and 2 |

10 kΩ or higher |

| NG | .gif) |

REPLACE SEC HORN RELAY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (SEC HORN RELAY POWER SOURCE) |

|

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

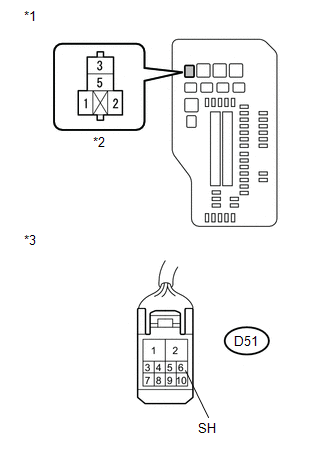

CHECK HARNESS AND CONNECTOR (SEC HORN RELAY - MAIN BODY ECU) |

|

(a) Disconnect the D51 main body ECU (driver side junction block assembly) connector. |

|

(b) Measure the resistance on the relay block side according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Engine room relay block SEC HORN relay terminal 1 - D51-6 (SH) |

Always |

Below 1 Ω |

|

Engine room relay block SEC HORN relay terminal 1 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Engine Room Relay Block |

|

*2 |

SEC HORN Relay Terminal |

|

*3 |

Front view of wire harness connector (to Main Body ECU (Driver Side Junction Block Assembly)) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (SEC HORN RELAY POWER SOURCE) |

|

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

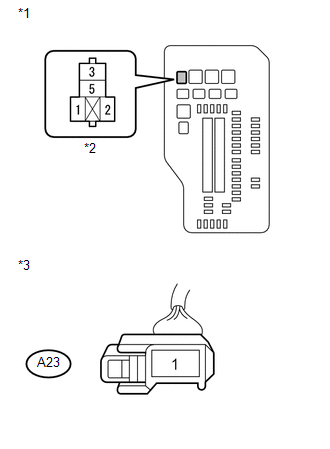

7. |

CHECK HARNESS AND CONNECTOR (SEC HORN RELAY - SECURITY HORN ASSEMBLY) |

|

(a) Disconnect the A23 security horn assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Engine room relay block SEC HORN relay terminal 5 - A23-1 |

Always |

Below 1 Ω |

|

Engine room relay block SEC HORN relay terminal 5 - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Engine Room Relay Block |

|

*2 |

SEC HORN Relay Terminal |

|

*3 |

Front view of wire harness connector (to Security Horn Assembly) |

| OK | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Horn Circuit

Horn Circuit

DESCRIPTION

When the theft deterrent system is switched from the armed state to the alarm

sounding state, the main body ECU (driver side junction block assembly) transmits

a signal to cause the h ...

Security Indicator Light Circuit

Security Indicator Light Circuit

DESCRIPTION

Even when the theft deterrent system is in the disarmed state, the security indicator

blinks due to a signal output from the immobiliser system. The security indicator

blinks continuo ...

Other materials about Toyota Venza:

Parking brake

Sets the parking brake* (Depressing the pedal again releases the parking brake.)

*: Fully depress the parking brake pedal with your left foot while depressing

the brake pedal with your right foot.

- Usage in winter time

NOTICE

- Before driv ...

Main Body ECU Vehicle Information Reading/Writing Process Malfunction (B15F6)

DESCRIPTION

This DTC is stored when items controlled by the main body ECU (multiplex network

body ECU) cannot be customized via the navigation system vehicle customization screen.

HINT:

The main body ECU (multiplex network body ECU) controls the items ...

System Description

SYSTEM DESCRIPTION

1. POWER MIRROR CONTROL SYSTEM DESCRIPTION

(a) This system has the following functions: power retract mirror function*,

reverse shift-linked function, electrical remote control function, memory function

and mirror heater function.

...

0.129

.gif)

.gif) ).

)..png)