Toyota Venza: Horn Circuit

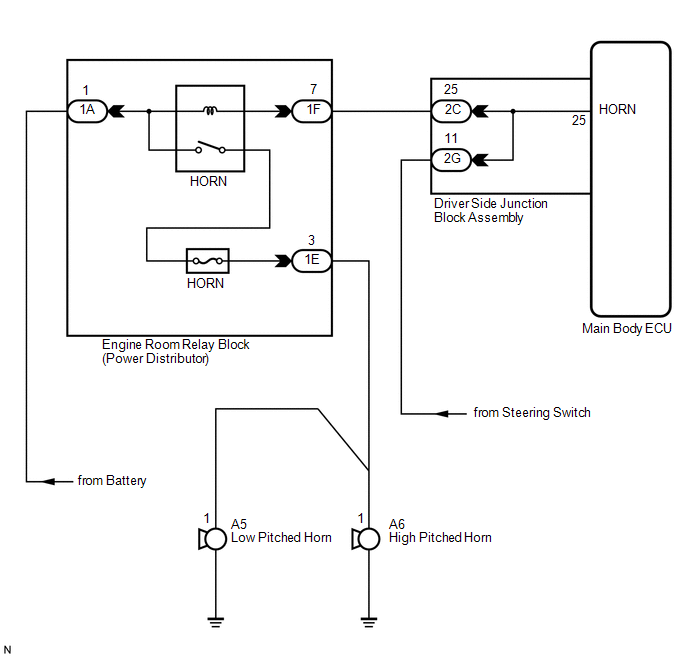

DESCRIPTION

When the theft deterrent system is switched from the armed state to the alarm sounding state, the main body ECU (driver side junction block assembly) transmits a signal to cause the horn to sound at intervals of 0.4 seconds.

WIRING DIAGRAM

PROCEDURE

|

1. |

INSPECT HORNS |

(a) Press the horn switch and check if the horns sound.

|

Result |

Proceed to |

|---|---|

|

Horns sound |

A |

|

Horns do not sound |

B |

| B | .gif) |

GO TO HORN SYSTEM |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Select the item below in the Active Test and then check that the horns operate.

Main Body|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Vehicle Horn |

Vehicle horns |

ON / OFF |

- |

OK:

The vehicle horns sound and stop correctly when operated through the Techstream.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEMBLY) |

Engine Hood Courtesy Switch Circuit

Engine Hood Courtesy Switch Circuit

DESCRIPTION

The security courtesy switch is installed together with the hood lock. This switch

turns off when the engine hood is opened and turns on when the engine hood is closed.

WIRING DIAGRAM

...

Security Horn Circuit

Security Horn Circuit

DESCRIPTION

When the theft deterrent system is switched from the armed state to the alarm

sounding state, the main body ECU (driver side junction block assembly) controls

the security horn.

WIRI ...

Other materials about Toyota Venza:

Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical

(Shift Solenoid Valve SLU) (P2759)

DESCRIPTION

The amount of current flow to the solenoid is controlled by the duty ratio of

the TCM output signal. The higher the duty ratio becomes, the higher the lock-up

hydraulic pressure becomes during the lock-up operation.

DTC No.

...

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

The wireless door lock control system troubleshooting procedures are

based on the premise that the power door lock control system is operating

normally. Check the power door lock control system first before troub ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEELS

2. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the 2 nuts and front stabilizer link assembly LH.

HINT:

If the ball joint turns together with the nut, use a hexagon wrench (6

mm) to hold ...

0.1607

.gif)