Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

3. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

4. REMOVE NO. 1 ENGINE UNDER COVER

5. REMOVE NO. 2 ENGINE UNDER COVER

6. DRAIN ENGINE COOLANT

.gif)

7. REMOVE V-RIBBED BELT

HINT:

See page .gif)

8. REMOVE WIRE HARNESS CLAMP BRACKET

.gif)

9. REMOVE GENERATOR ASSEMBLY

.gif)

10. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

.gif)

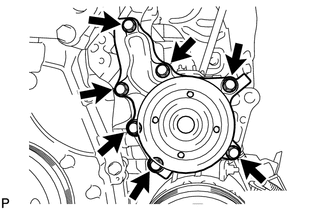

11. REMOVE WATER PUMP ASSEMBLY

|

(a) Remove the 7 bolts, water pump and water pump gasket. |

|

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT FOR COOLANT LEAK

HINT:

The sliding surface inside the engine water pump assembly is lubricated

by engine coolant. As some engine coolant is d ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL WATER PUMP ASSEMBLY

(a) Install a new gasket and the water pump with the 7 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL INJECTOR ASSEMBLY

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly

(See page ).

(a) Apply a light coat of gasoline or spindle oil to new O-rings, and

then ...

Passenger Side Buckle Switch Circuit Malfunction (B1771)

DESCRIPTION

The passenger side buckle switch circuit consists of the occupant classification

ECU and front seat inner belt assembly RH.

DTC B1771 is recorded when a malfunction is detected in the passenger side buckle

switch circuit.

Troubleshoot DTC B1 ...

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL REAR DRIVE SHAFT DUST COVER

(a) Using SST and a steel plate, install a new rear drive shaft dust

cover to the rear drive shaft inboard joint assembly.

Text in Illustration

*1

...

0.1728