Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE TAIL EXHAUST PIPE ASSEMBLY (for 1AR-FE)

.gif)

2. REMOVE TAIL EXHAUST PIPE ASSEMBLY (for 2GR-FE)

.gif)

3. REMOVE CENTER EXHAUST PIPE ASSEMBLY (for 1AR-FE)

.gif)

4. REMOVE CENTER EXHAUST PIPE ASSEMBLY (for 2GR-FE)

.gif)

5. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Depress the brake pedal and hold it.

|

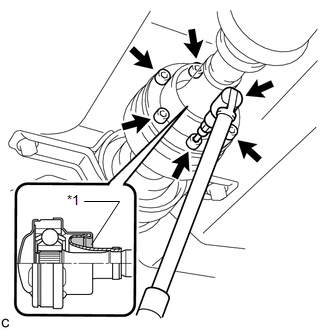

(b) Using a hexagon wrench (6 mm), loosen the cross groove joint set bolts 1/2 turn. NOTICE:

|

|

|

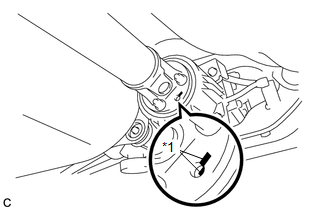

(c) Place matchmarks on the rear propeller shaft and electromagnetic control coupling assembly. Text in Illustration

|

|

|

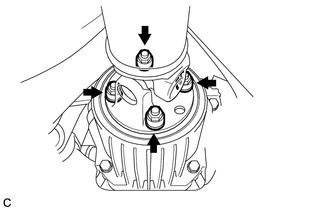

(d) Remove the 4 nuts and 4 washers. |

|

|

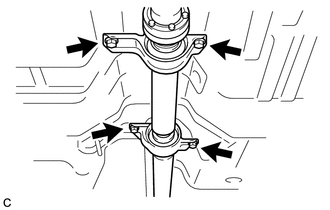

(e) Using a brass bar and a hammer, separate the propeller with center bearing shaft assembly. |

|

|

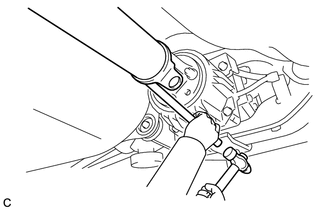

(f) Remove the 4 bolts, 2 No. 1 center support bearing washers and 2 No. 2 center support bearing washers. NOTICE: When removing the bolts and washers, do not apply excessive force to the universal joint. |

|

(g) Pull out the propeller with center bearing shaft assembly from the transfer.

NOTICE:

- When removing the propeller shaft, do not apply excessive force to the universal joint.

- During and after the removal of the propeller shaft, keep the universal joint angle straight (within 15 degrees).

- Be careful not to damage the oil seal.

|

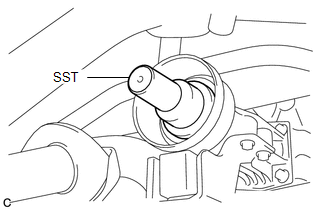

(h) Insert SST into the transfer to prevent oil leaks. SST: 09325-20010 NOTICE: Be careful not to damage the oil seal. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE PROPELLER SHAFT

(a) Place matchmarks on both flanges.

Text in Illustration

*1

Matchmark

...

Other materials about Toyota Venza:

Pressure Control Solenoid "A" Performance (Shift Solenoid Valve SL1) (P0746)

SYSTEM DESCRIPTION

The TCM uses the vehicle speed signal and signals from the transmission speed

sensors (NC, NT) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).

Then the TCM compares the actual gear with the shift schedule in the TCM memo ...

Touch Sensor Circuit

DESCRIPTION

When the power back door ECU receives a jam signal from the touch sensor while

the power back door is operating, the ECU reverses the back door operation and opens

the door.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE US ...

Throttle / Pedal Position Sensor / Switch "D" Circuit (P2120,P2122,P2123,P2125,P2127,P2128,P2138)

DESCRIPTION

HINT:

This Electronic Throttle Control System (ETCS) does not use a throttle

cable.

These DTCs relate to the accelerator pedal sensor assembly.

The accelerator pedal sensor assembly is mounted on the accelerator pedal brack ...

0.1424