Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL NO. 1 CENTER SUPPORT BEARING ASSEMBLY

|

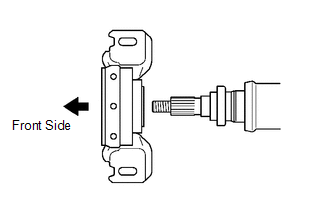

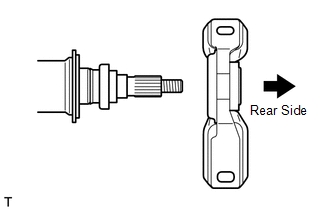

(a) Set the No. 1 center support bearing on the intermediate shaft as shown in the illustration. NOTICE: Make sure to install the bearing in the correct position. |

|

(b) Install a new washer to the intermediate shaft.

|

(c) Align the matchmarks on the universal joint flange and intermediate shaft and place the flange on the shaft. Text in Illustration

|

|

|

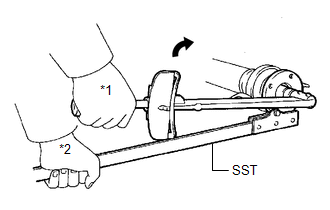

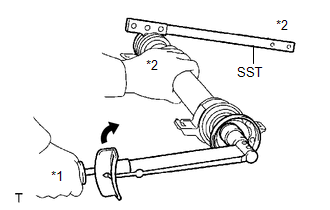

(d) Using SST to hold the universal joint flange, press the No. 1 center support bearing assembly into position by tightening a new nut and washer. SST: 09330-00021 Torque: 182 N·m {1851 kgf·cm, 134 ft·lbf} Text in Illustration

|

|

(e) Loosen the nut.

(f) Tighten the nut again.

Torque:

69 N·m {701 kgf·cm, 51 ft·lbf}

|

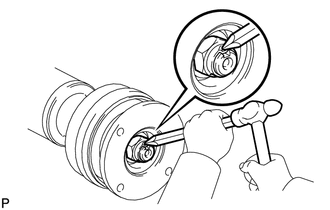

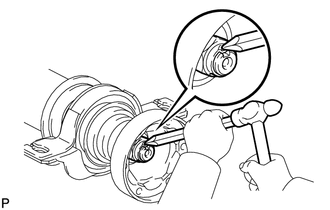

(g) Using a chisel and a hammer, stake the nut. |

|

2. INSTALL NO. 2 CENTER SUPPORT BEARING ASSEMBLY

|

(a) Set the No. 2 center support bearing on the intermediate shaft as shown in the illustration. NOTICE: Make sure to install the bearing in the correct position. |

|

(b) Install a new washer to the intermediate shaft.

|

(c) Align the matchmarks on the universal joint flange and intermediate shaft, and place the flange on the shaft. Text in Illustration

|

|

|

(d) Using SST to hold the universal joint flange, press the No. 2 center support bearing assembly into position by tightening a new nut and washer. SST: 09330-00021 Torque: 182 N·m {1851 kgf·cm, 134 ft·lbf} Text in Illustration

|

|

(e) Loosen the nut.

(f) Tighten the nut again.

Torque:

69 N·m {701 kgf·cm, 51 ft·lbf}

|

(g) Using a chisel and a hammer, stake the nut. |

|

3. INSTALL INTERMEDIATE SHAFT

|

(a) Align the matchmarks on the intermediate shaft and rear propeller shaft, and then install 2 washers and 6 bolts. Text in Illustration

|

|

(b) Using a hexagon wrench (6 mm), tighten the 6 bolts with 2 washers temporarily.

4. INSTALL PROPELLER SHAFT

(a) Align the matchmarks on the propeller shaft and the universal joint flange.

|

(b) Install the propeller shaft to the front flange with the 4 bolts, 4 washers and 4 nuts. Torque: 74 N·m {750 kgf·cm, 55 ft·lbf} NOTICE:

|

|

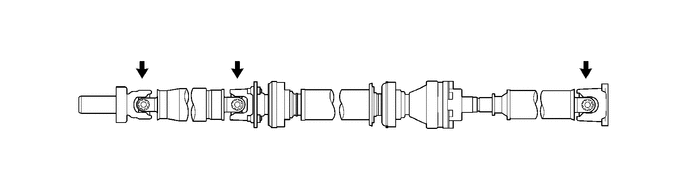

(c) Check that each joint of the propeller with center bearing shaft assembly is facing the direction shown in the illustration.

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Remove SST from the transfer.

SST: 09325-20010

...

Propeller Shaft System

Propeller Shaft System

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symp ...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY

(a) Apply a light coat of gasoline or spindle oil to a new O-ring.

Text in Illustration

*1

O-ring

...

Mass or Volume Air Flow Circuit Low Input (P0102,P0103)

DESCRIPTION

The mass air flow meter is a sensor that measures the amount of air flowing through

the throttle valve. The ECM uses this information to determine the fuel injection

time and to provide the appropriate air-fuel ratio.

Inside the mass air flow ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

(a) Lighting system data can be read from the Data Link Connector 3 (DLC3) of

the vehicle. When the system seems to be malfunctioning, use the Techstream to check

for malfunctions and perform repairs.

2. CHECK DLC3

(a) C ...

0.1163

.png)

.png)

.png)

.png)