Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL ECM

|

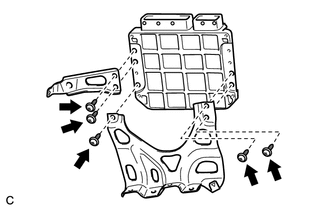

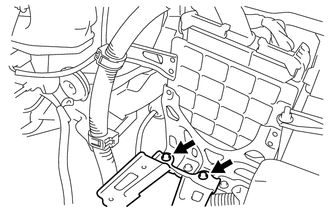

(a) Install the bracket to the ECM with the 5 screws. |

|

|

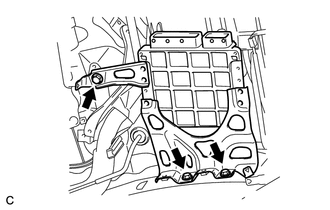

(b) Install the ECM with the 3 bolts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

|

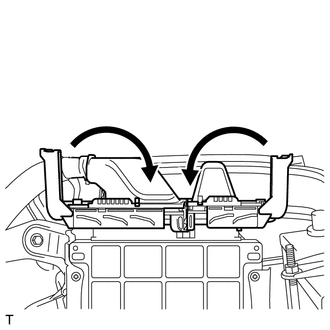

(c) Connect the 2 ECM connectors and lower the 2 levers. NOTICE:

|

|

|

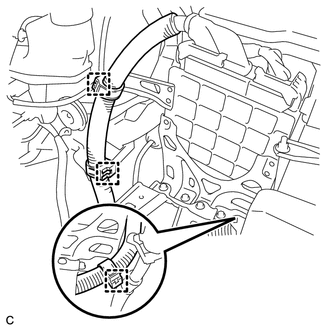

(d) Install the 3 wire harness clamps. |

|

2. INSTALL AIR CLEANER BRACKET

|

(a) Install the air cleaner bracket with the 2 bolts. Torque: 7.8 N·m {80 kgf·cm, 69 in·lbf} |

|

3. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

.gif)

4. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

.gif)

5. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

.gif)

6. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

.gif)

7. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

8. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

.gif)

9. INSTALL WINDSHIELD WIPER MOTOR AND LINK

(a) Install the windshield wiper motor and link (See page

.gif) ).

).

10. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

11. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

CAUTION:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

12. PERFORM REGISTRATION

(a) The Vehicle Identification Number (VIN) must be input into a replacement

ECM (See page .gif) ).

).

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE WINDSHIELD WIPER MOTOR AND LINK

(a) Remove the windshield wiper motor and link (See page

).

2. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

3. REMOVE COOL AIR INTAKE ...

Other materials about Toyota Venza:

Throttle / Pedal Position Sensor "A" Minimum Stop Performance (P2109)

DESCRIPTION

The idle speed is controlled by the Electronic Throttle Control System (ETCS).

The ETCS is comprised of a throttle actuator, which operates the throttle valve,

and a throttle position sensor, which detects the opening amount of the throttle

...

Terminals Of Ecu

TERMINALS OF ECU

HINT:

Check from the rear of the connector while it is connected to the components.

1. NAVIGATION RECEIVER ASSEMBLY

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

The ECM controls the cruise control system of the vehicle. The data and DTCs

relating to the cruise control system can be read from the DLC3 of the vehicle.

If either DTC or CRUISE OK is not displayed on the multi-informat ...

0.1218