Toyota Venza: Installation

INSTALLATION

PROCEDURE

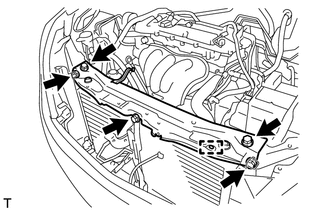

1. INSTALL RADIATOR ASSEMBLY

|

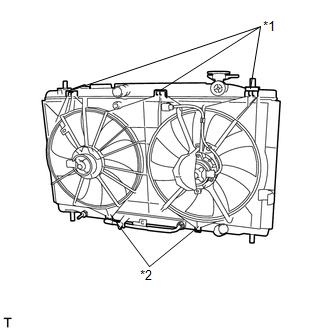

(a) Install the fan assembly with motor to the radiator with the 2 guides at the bottom and 3 snap fits on the top. Text in Illustration

|

|

(b) Install the 2 lower radiator supports and 2 radiator support cushions.

|

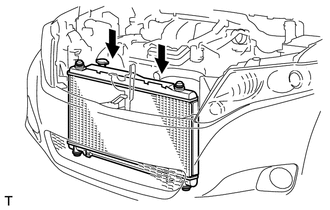

(c) Install the radiator assembly and fan assembly with motor. NOTICE: Do not apply any excessive force to the cooler condenser assembly or pipe when installing the radiator assembly. |

|

|

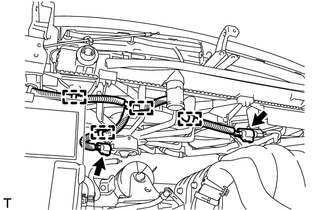

(d) Connect the 4 wire harness clamps and 2 connectors. |

|

2. INSTALL COOLER CONDENSER ASSEMBLY

|

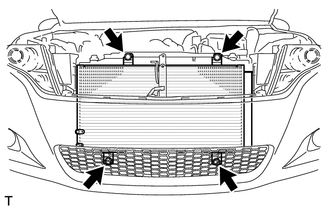

(a) Install the cooler condenser assembly with the 4 bolts. Torque: 5.0 N·m {51 kgf·cm, 44 in·lbf} |

|

3. INSTALL UPPER RADIATOR SUPPORT

|

(a) Install the upper radiator support with the 5 bolts and connect the hood lock control cable clamp to the upper radiator support. Torque: 12 N·m {122 kgf·cm, 9 ft·lbf} |

|

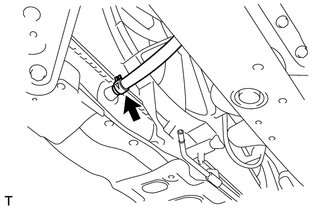

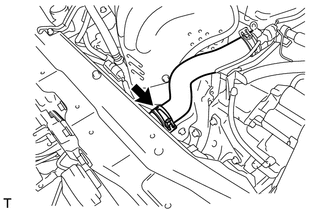

4. CONNECT OUTLET NO. 1 OIL COOLER HOSE

|

(a) Connect the outlet No. 1 oil cooler hose to the radiator. |

|

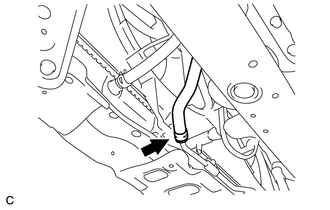

5. CONNECT INLET NO. 1 OIL COOLER HOSE

|

(a) Connect the inlet No. 1 oil cooler hose to the radiator. |

|

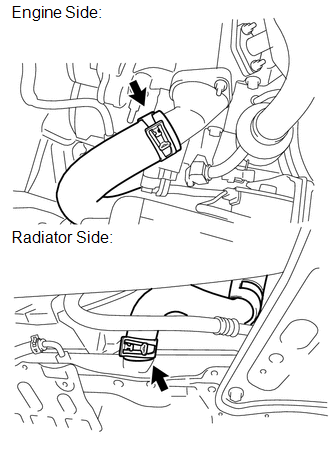

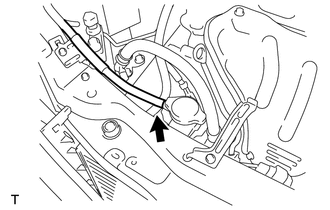

6. INSTALL NO. 2 RADIATOR HOSE

|

(a) Install the No. 2 radiator hose to the engine and radiator. |

|

7. CONNECT NO. 1 RADIATOR HOSE

|

(a) Connect the No. 1 radiator hose to the radiator. |

|

8. CONNECT OUTLET RESERVE TANK HOSE

|

(a) Connect the outlet reserve tank hose to the radiator. |

|

9. INSTALL HOOD LOCK ASSEMBLY (w/o Engine Hood Courtesy Switch)

.gif)

10. INSTALL HOOD LOCK ASSEMBLY (w/ Engine Hood Courtesy Switch)

.gif)

11. INSTALL LOW PITCHED HORN ASSEMBLY

.gif)

12. INSTALL HIGH PITCHED HORN ASSEMBLY

.gif)

13. INSTALL RADIATOR GRILLE

.gif)

14. INSTALL INLET AIR CLEANER ASSEMBLY

.gif)

15. ADD ENGINE COOLANT

.gif)

16. INSPECT FOR COOLANT LEAK

.gif)

17. INSPECT AUTOMATIC TRANSAXLE FLUID

HINT:

- U760F Automatic transaxle: See page

.gif)

- U760E Automatic transaxle: See page

.gif)

18. INSTALL NO. 1 ENGINE UNDER COVER

19. INSTALL NO. 2 ENGINE UNDER COVER

20. INSTALL COOL AIR INTAKE DUCT SEAL

.gif)

On-vehicle Inspection

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK RADIATOR CAP SUB-ASSEMBLY

(a) Measure the valve opening pressure.

(1) If there are water stains or foreign matter on rubber packings 1, 2 or 3,

clean t ...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER

2. REMOVE NO. 2 ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT

4. REMOVE COOL AIR INTAKE DUCT SEAL

5. REMOVE INLET AIR CLEANER ASSEMBLY

...

Other materials about Toyota Venza:

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT DOOR LOCK ASSEMBLY

NOTICE:

When reusing the removed front door lock assembly, replace the door

lock wiring harness seal on the connector with a new one.

Do not allow grease or dust to adhere to the do ...

License Plate Light Assembly

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL LICENSE PLATE LIGHT ASSEMBLY

(a) Engage the 2 claws to install the license plate light assembly.

...

Engine Hood Courtesy Switch Circuit

DESCRIPTION

The security courtesy switch is installed together with the hood lock. This switch

turns off when the engine hood is opened and turns on when the engine hood is closed.

WIRING DIAGRAM

PROCEDURE

1.

INSPECT HOOD LOCK AS ...

0.1174