Toyota Venza: On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK RADIATOR CAP SUB-ASSEMBLY

(a) Measure the valve opening pressure.

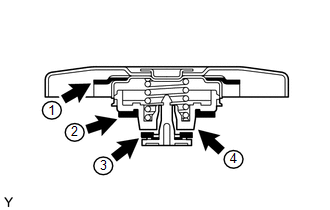

(1) If there are water stains or foreign matter on rubber packings 1, 2 or 3, clean the part(s) with water and finger scouring.

(2) Check that rubber packings 1, 2 and 3 are not deformed, cracked or swollen.

(3) Check that 3 and 4 are not stuck together.

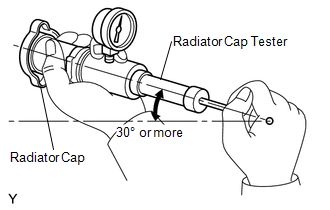

(4) Apply engine coolant to rubber packings 2 and 3 before using the radiator cap tester.

|

(5) When using the cap tester, tilt it to 30° or more above level. |

|

(6) Pump the cap tester several times, and check the maximum pressure*.

Pump speed:

1 pump per second

*: Even if the cap cannot maintain the maximum pressure, it is not a defect.

Judgment Criterion:

|

Item |

Specified Condition |

|---|---|

|

Standard value (for brand-new cap) |

94 to 122 kPa (1.0 to 1.2 kgf/cm2, 13.6 to 17 psi) |

|

Minimum standard value (for used cap) |

79 kPa (0.8 kgf/cm2, 11.4 psi) |

If the measured maximum pressure is less than the minimum standard value, replace the radiator cap sub-assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL RADIATOR ASSEMBLY

(a) Install the fan assembly with motor to the radiator with the 2 guides

at the bottom and 3 snap fits on the top.

Text in Ill ...

Other materials about Toyota Venza:

Voice Guidance does not Function

PROCEDURE

1.

CHECK VOICE GUIDANCE

(a) Check that the voice guidance settings are not off.

OK:

Voice guidance settings are not off.

NG

CHANGE THE VOICE GUIDANCE SETTINGS TO ON

...

Room Oscillator does not Recognize Key

DESCRIPTION

If the room oscillator does not recognize a key, one of the following may be

the cause: 1) communication between the indoor electrical key oscillator (for front

floor) and key cannot be performed; 2) communication between the indoor electrical ...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

0.1487