Toyota Venza: Inspection

INSPECTION

PROCEDURE

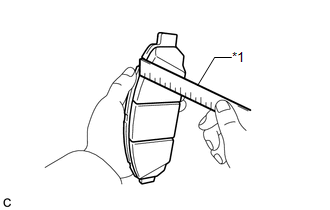

1. INSPECT PAD LINING THICKNESS

|

(a) Using a ruler, measure the pad lining thickness. Text in Illustration

Standard thickness of a new pad: 12.0 mm (0.472 in.) Minimum thickness: 1.0 mm (0.0394 in.) If the pad lining thickness is equal to or less than the minimum, replace the disc brake pads. HINT: Be sure to check the wear of the front disc after replacing the brake pads with new ones. |

|

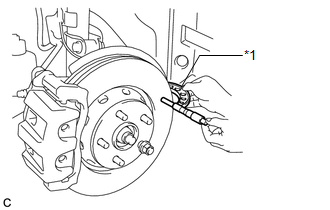

2. INSPECT DISC THICKNESS

|

(a) Using a micrometer, measure the disc thickness. Text in Illustration

Standard thickness of a new disc: 28.0 mm (1.10 in.) Minimum thickness: 26.0 mm (1.02 in.) HINT: If the disc thickness is less than the minimum, replace the front disc. |

|

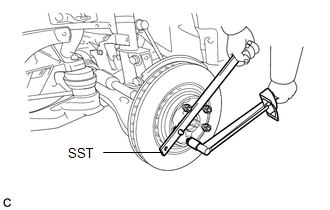

3. INSPECT DISC RUNOUT

(a) Inspect the front axle hub bearing looseness and front axle hub runout (See

page .gif) ).

).

|

(b) Using SST to hold the disc, tighten the disc with the 5 hub nuts. SST: 09330-00021 Torque: 103 N·m {1050 kgf·cm, 76 ft·lbf} |

|

|

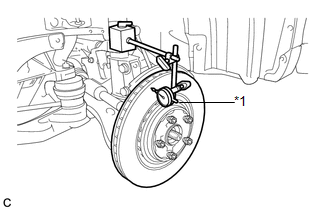

(c) Using a dial indicator, measure the disc runout 10 mm (0.394 in.) away from the outer edge of the front disc. Text in Illustration

Maximum disc runout: 0.05 mm (0.00197 in.) If the runout exceeds the maximum, change the installation position of the disc to minimize runout. If the runout exceeds the maximum even when the installation position is changed, grind the disc. If the disc thickness is less than the minimum, replace the front disc. NOTICE: Keep the magnetic parts of the dial indicator away from the front axle hub and speed sensor. |

|

(d) Remove the 5 hub nuts and front disc.

Removal

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the LH side and RH side.

The following procedure listed is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEEL

2. ...

Installation

Installation

INSTALLATION

PROCEDURE

1. TEMPORARILY TIGHTEN FRONT DISC BRAKE BLEEDER PLUG

(a) Temporarily tighten the front disc brake bleeder plug.

HINT:

Fully tighten the front disc brake bleeder plug after ...

Other materials about Toyota Venza:

How To Proceed With Troubleshooting

CAUTION / NOTICE / HINT

HINT:

The wireless door lock control system troubleshooting procedures are

based on the premise that the power door lock control system is operating

normally. Check the power door lock control system first before troub ...

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEELS

2. REMOVE FRONT STABILIZER LINK ASSEMBLY LH

(a) Remove the 2 nuts and front stabilizer link assembly LH.

HINT:

If the ball joint turns together with the nut, use a hexagon wrench (6

mm) to hold ...

Lost Communication with ECM / PCM "A" (U0100)

DESCRIPTION

The power management control ECU receives shift position information from 2 sources.

It receives a shift position P signal from the shift lock control unit assembly

via a direct line, and shift position information from the ECM via CAN. If the ...

0.1547