Toyota Venza: Installation

INSTALLATION

PROCEDURE

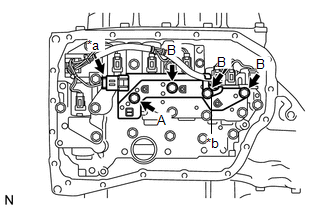

1. INSTALL ATF TEMPERATURE SENSOR ASSEMBLY

|

(a) Coat a new O-ring with ATF and install it to the ATF temperature sensor assembly. Text in Illustration

|

|

(b) Coat the 4 bolts with ATF.

|

(c) Install the ATF temperature sensor assembly and clamp to the transmission valve body assembly with the 4 bolts. Text in Illustration

Torque: 11 N·m {112 kgf·cm, 8 ft·lbf} Bolt length: Bolt (A) 25 mm (0.984 in.) Bolt (B) 85 mm (3.35 in.) |

|

(d) Connect the ATF temperature sensor assembly connector.

2. INSTALL VALVE BODY OIL STRAINER ASSEMBLY

.gif)

3. INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

.gif)

4. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Install Automatic Transaxle Assembly" through "Install Engine

Assembly with Transaxle" (See page .gif) ).

).

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT ATF TEMPERATURE SENSOR ASSEMBLY

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Test ...

Atf Temperature Sensor(when Using The Engine Support Bridge)

Atf Temperature Sensor(when Using The Engine Support Bridge)

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT ATF TEMPERATURE SENSOR ASSEMBLY

(a) Measure the resistance according to the value(s) in the table ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Side doors

The vehicle can be locked and unlocked using the entry function, wireless

remote control, key or door lock switch.

- Entry function (vehicles with smart key system)

- Wireless remote control

- Key

► Vehicles with smart key system ...

Diagnosis System

DIAGNOSIS SYSTEM

1. DESCRIPTION

When troubleshooting a vehicle with a diagnosis system, the only difference from

the usual troubleshooting procedure is connecting the Techstream to the vehicle

and reading various data output from the vehicle's skid c ...

0.135

.png)