Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT SOLENOID VALVE SL

|

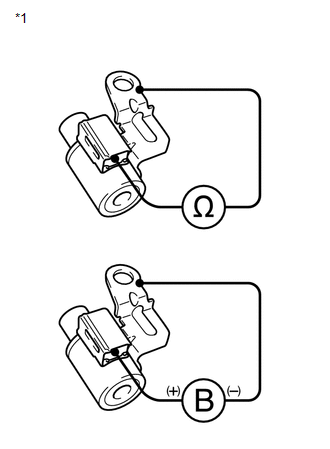

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

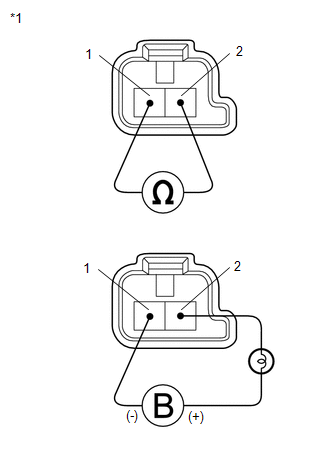

(b) Connect a positive (+) battery lead to the terminal of the solenoid connector, and a negative (-) battery lead to the solenoid body, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

2. INSPECT SHIFT SOLENOID VALVE SLT

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

(b) Connect a positive (+) battery lead with a 21 W bulb to terminal 2 and a negative (-) battery lead to terminal 1 of the solenoid valve connector, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

3. INSPECT SHIFT SOLENOID VALVE SLU

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

(b) Connect a positive (+) battery lead with a 21 W bulb to terminal 2 and a negative (-) battery lead to terminal 1 of the solenoid valve connector, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

4. INSPECT SHIFT SOLENOID VALVE SL1

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

(b) Connect a positive (+) battery lead with a 21 W bulb to terminal 2 and a negative (-) battery lead to terminal 1 of the solenoid valve connector, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

5. INSPECT SHIFT SOLENOID VALVE SL2

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

(b) Connect a positive (+) battery lead with a 21 W bulb to terminal 2 and a negative (-) battery lead to terminal 1 of the solenoid valve connector, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

6. INSPECT SHIFT SOLENOID VALVE SL3

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

(b) Connect a positive (+) battery lead with a 21 W bulb to terminal 2 and a negative (-) battery lead to terminal 1 of the solenoid valve connector, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

7. INSPECT SHIFT SOLENOID VALVE SL4

|

(a) Measure the resistance according to the value(s) in the table below. Text in Illustration

Standard Resistance:

If the value is not as specified, replace the shift solenoid valve. |

|

(b) Connect a positive (+) battery lead with a 21 W bulb to terminal 2 and a negative (-) battery lead to terminal 1 of the solenoid valve connector, and check the operation of the valve.

NOTICE:

When using battery voltage during the inspection, do not bring the positive (+) and negative (-) tester probes too close to each other as a short circuit may occur.

OK:

The valve moves and makes an operating sound.

If the operation cannot be done as specified, replace the shift solenoid valve.

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Remove Engine Assembly with transaxle" through "Remove Automatic

Transaxle Assembly" (See p ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT SOLENOID VALVE SL4

(a) Coat the shift solenoid valve SL4 and bolt with ATF.

Text in Illustration

*1

Lock Pla ...

Other materials about Toyota Venza:

Rear Door RH ECU Communication Stop (B2323)

DESCRIPTION

This DTC is stored when LIN communication between the power window regulator

motor assembly (for rear RH side) and main body ECU (driver side junction block

assembly) stops for more than 10 seconds.

DTC No.

DTC Detection ...

Driving assist systems

To help enhance driving safety and performance, the following systems operate

automatically in response to various driving situations.

Be aware, however, that these systems are supplementary and should not be relied

upon too heavily when operating the veh ...

Reverse Signal Circuit

DESCRIPTION

The radio and display receiver assembly receives a reverse signal from the park/neutral

position switch assembly.

WIRING DIAGRAM

PROCEDURE

1.

CHECK BACK-UP LIGHT

(a) Move the shift lever to R and check if th ...

0.1305