Toyota Venza: Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL SHIFT SOLENOID VALVE SL4

|

(a) Coat the shift solenoid valve SL4 and bolt with ATF. Text in Illustration

|

|

(b) Install the shift solenoid valve SL4 and lock plate to the valve body assembly with the bolt.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

2. INSTALL SHIFT SOLENOID VALVE SL3

|

(a) Coat the shift solenoid valve SL3 and bolt with ATF. Text in Illustration

|

|

(b) Install the shift solenoid valve SL3 and lock plate to the valve body assembly with the bolt.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

3. INSTALL SHIFT SOLENOID VALVE SL1

|

(a) Coat the shift solenoid valve SL1 with ATF. Text in Illustration

|

|

(b) Install the shift solenoid valve SL1 to the valve body assembly.

4. INSTALL SHIFT SOLENOID VALVE SL2

(a) Coat the shift solenoid valve SL2 and bolt with ATF.

(b) Install the shift solenoid valve SL2 and lock plate to the valve body assembly with the bolt.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

5. INSTALL SHIFT SOLENOID VALVE SLU

|

(a) Coat the shift solenoid valve SLU with ATF. Text in Illustration

|

|

(b) Install the shift solenoid valve SLU to the valve body assembly.

6. INSTALL SHIFT SOLENOID VALVE SLT

(a) Coat the shift solenoid valve SLT with ATF.

(b) Install the shift solenoid valve SLT and lock plate to the valve body assembly.

7. INSTALL SHIFT SOLENOID VALVE SL

|

(a) Coat the shift solenoid valve SL with ATF. |

|

(b) Install the shift solenoid valve SL to the valve body assembly.

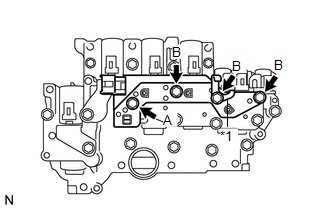

8. INSTALL ATF TEMPERATURE SENSOR ASSEMBLY

|

(a) Coat a new O-ring with ATF and install it to the ATF temperature sensor assembly. Text in Illustration

|

|

|

(b) Coat the 4 bolts with ATF. Text in Illustration

|

|

(c) Install the ATF temperature sensor assembly and clamp to the valve body assembly with the 4 bolts.

Torque:

11 N·m {112 kgf·cm, 8 ft·lbf}

Bolt length:

Bolt A

25 mm (0.984 in.)

Bolt B

85 mm (3.35 in.)

9. INSTALL TRANSMISSION WIRE

.gif)

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT SOLENOID VALVE SL

(a) Measure the resistance according to the value(s) in the table below.

Text in Illustration

*1

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL MANUAL VALVE

(a) Coat the manual valve with ATF and install it to the transmission

valve body assembly.

...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Tires

Replace or rotate tires in accordance with maintenance schedules and treadwear.

- Checking tires

1. New tread

2. Treadwear indicator

3. Worn tread

The location of treadwear indicators is shown by the “TWI” or “Δ” marks, etc.,

molded ...

0.1767

.png)

.png)

.png)

.png)

.png)

.png)