Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

HINT:

See the steps from "Remove Engine Assembly with transaxle" through "Remove Automatic

Transaxle Assembly" (See page .gif) ).

).

2. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

|

(a) Remove the 18 bolts and automatic transaxle oil pan sub-assembly from the automatic transaxle assembly. NOTICE: Some fluid will remain in the automatic transaxle oil pan sub-assembly. Remove all the bolts, and carefully remove the automatic transaxle oil pan sub-assembly. |

|

(b) Remove the automatic transaxle oil pan gasket from the automatic transaxle oil pan sub-assembly.

|

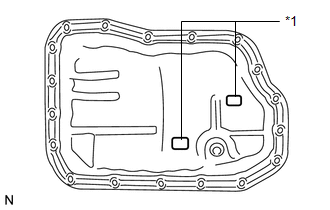

(c) Remove the 2 transmission oil cleaner magnets from the automatic transaxle oil pan sub-assembly. Text in Illustration

|

|

|

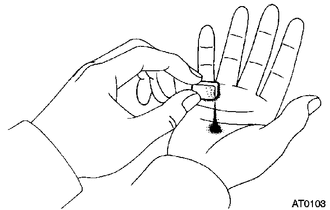

(d) Examine particles in the automatic transaxle oil pan sub-assembly. (1) Use the removed transmission oil cleaner magnets to collect any steel chips. Examine the chips and particles in the automatic transaxle oil pan sub-assembly and on the transmission oil cleaner magnets to determine what type of wear has occurred in the automatic transaxle assembly: Result: Steel (magnetic) Bearing, gear and plate wear Brass (non-magnetic) Bushing wear |

|

3. REMOVE VALVE BODY OIL STRAINER ASSEMBLY

|

(a) Remove the 2 bolts and valve body oil strainer assembly from the transmission valve body assembly. |

|

|

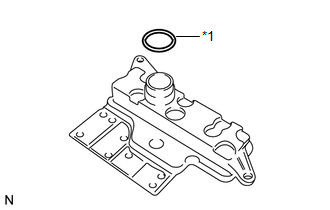

(b) Remove the O-ring from the valve body oil strainer assembly. Text in Illustration

|

|

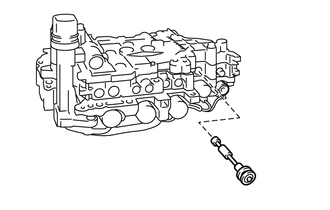

4. REMOVE TRANSMISSION VALVE BODY ASSEMBLY

|

(a) Remove the 11 bolts and transmission valve body assembly from the automatic transaxle assembly. NOTICE: When removing the transmission valve body assembly, be careful not to allow the speed sensor and the automatic transaxle assembly to interfere with each other. |

|

5. REMOVE MANUAL VALVE

|

(a) Remove the manual valve from the transmission valve body assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE TRANSMISSION WIRE

2. REMOVE ATF TEMPERATURE SENSOR ASSEMBLY

(a) Remove the 4 bolts, ATF temperature sensor assembly and clamp from

the valve body ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT SOLENOID VALVE SL

(a) Measure the resistance according to the value(s) in the table below.

Text in Illustration

*1

...

Other materials about Toyota Venza:

Door Control Transmitter(w/o Smart Key System)

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE TRANSMITTER HOUSING COVER

2. REMOVE DOOR CONTROL TRANSMITTER MODULE

Inspection

INSPECTION

PROCEDURE

1. INSPECT DOOR CONTROL TRANSMITTER

(a) Inspect operation of th ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

2. SEPARATE NO. 3 PARKING BRAKE CABLE ASSEMBLY

(a) Remov ...

Disabling the TRAC system

If the vehicle gets stuck in mud, dirt or snow, the TRAC system may reduce power

from the engine to the wheels. Pressing

to turn the system off may make it

easier for you to rock the vehicle in order to free it.

To turn the TRAC system off, quickly pr ...

0.1633

.png)

.png)

.png)