Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT NO. 2 SPEAKER ASSEMBLY (for 6 Speakers)

(a) With the speaker installed, check that there is no looseness or other abnormalities.

(b) Check that there is no foreign matter in the speaker, no tears on the speaker cone or other abnormalities.

|

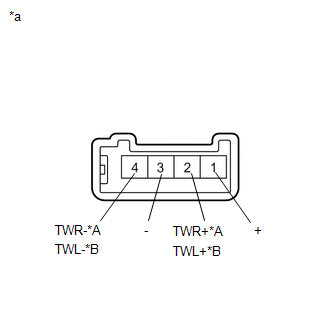

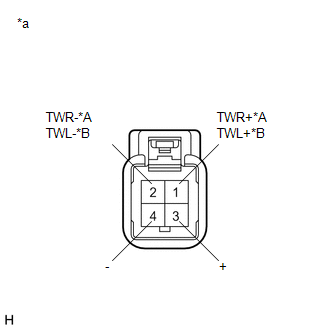

(c) Measure the resistance of the speaker. Standard Resistance:

If the result is not as specified, replace the speaker. Text in Illustration

|

|

(d) When there is a possibility that either the right or left speaker is malfunctioning, interchange the speakers and perform an inspection. If the malfunction disappears after interchanging the speakers, replace the malfunctioning speaker.

HINT:

Connect all connectors to the speakers when performing an inspection. If the result is not as specified, replace the speaker.

2. INSPECT FRONT NO. 2 SPEAKER ASSEMBLY (for 13 Speakers)

(a) With the speaker installed, check that there is no looseness or other abnormalities.

(b) Check that there is no foreign matter in the speaker, no tears on the speaker cone or other abnormalities.

|

(c) Measure the resistance of the speaker. Standard Resistance:

If the result is not as specified, replace the speaker. Text in Illustration

|

|

3. INSPECT FRONT NO. 3 SPEAKER ASSEMBLY (for 13 Speakers)

(a) With the speaker installed, check that there is no looseness or other abnormalities.

(b) Check that there is no foreign matter in the speaker, no tears on the speaker cone or other abnormalities.

|

(c) Measure the resistance of the speaker. Standard Resistance:

If the result is not as specified, replace the speaker. Text in Illustration

|

|

(d) When there is a possibility that either the right or left speaker is malfunctioning, interchange the speakers and perform an inspection. If the malfunction disappears after interchanging the speakers, replace the malfunctioning speaker.

HINT:

Connect all connectors to the speakers when performing an inspection. If the result is not as specified, replace the speaker.

4. INSPECT FRONT NO. 4 SPEAKER ASSEMBLY (for 13 Speakers)

(a) With the speaker installed, check that there is no looseness or other abnormalities.

(b) Check that there is no foreign matter in the speaker, no tears on the speaker cone or other abnormalities.

|

(c) Measure the resistance of the speaker. Standard Resistance:

If the result is not as specified, replace the speaker. Text in Illustration

|

|

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT FRONT DOOR OPENING TRIM WEATHERSTRIP

2. REMOVE FRONT PILLAR GARNISH

3. REMOVE NO. 2 INSTRUMENT PANEL SPEAKER PANEL SUB-ASSEMBLY

4. REMOVE FRONT NO. 4 SPEA ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT NO. 3 SPEAKER ASSEMBLY (for 13 Speakers)

(a) Engage the 3 claws to install the front No. 3 speaker assembly.

...

Other materials about Toyota Venza:

Certification ECU Vehicle Information Reading/Writing Process Malfunction (B15F7)

DESCRIPTION

This DTC is stored when items controlled by the certification ECU (smart key

ECU assembly) cannot be customized via the audio and visual system vehicle customization

screen.

HINT:

The certification ECU (smart key ECU assembly) controls the s ...

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

(a) Remove the No. 2 console box carpet.

...

Operation Check

OPERATION CHECK

1. CHECK NAVIGATION SYSTEM NORMAL CONDITION

(a) If the symptom is applicable to any of the following, it is intended behavior,

and not a malfunction.

Symptom

Answer

A longer route than expected is cho ...

0.1486