Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT LUMBAR SUPPORT ADJUSTER ASSEMBLY

(a) Check operation of the lumbar support adjuster.

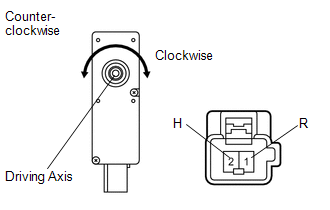

(1) Check if the lumbar support adjuster moves smoothly when the battery is connected to the lumbar support adjuster motor connector terminals.

OK:

|

Measurement Condition |

Operation Direction |

|---|---|

|

Battery positive (+) → 1 (R) Battery negative (-) → 2 (H) |

Clockwise |

|

Battery positive (+) → 2 (R) Battery negative (-) → 1 (H) |

Counterclockwise |

If the result is not as specified, replace the lumbar support adjuster assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT SEAT HEADREST ASSEMBLY

2. REMOVE FRONT SEAT REAR OUTER TRACK COVER

3. REMOVE FRONT SEAT REAR INNER TRACK COVER

4. REMOVE FRONT SEAT ASSEMBLY

5. REMOVE ...

Other materials about Toyota Venza:

Camshaft Position Sensor Circuit Malfunction (P0340,P0342,P0343)

DESCRIPTION

The camshaft position sensor (G signal sensor) for the intake camshaft consists

of a magnet and MRE (Magneto Resistance Element).

The camshaft has a timing rotor for the camshaft position sensor. When the camshaft

rotates, changes occur in th ...

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE COOL AIR INTAKE DUCT SEAL

3. REMOVE NO. 1 ENGINE CO ...

System Description

SYSTEM DESCRIPTION

1. SEAT BELT WARNING SYSTEM DESCRIPTION

If a seat belt is not fastened, this system flashes the seat belt warning light

or sounds the seat belt warning buzzer as a reminder.

(a) Driver side seat belt warning light:

When the driver side ...

0.1335