Toyota Venza: Engine Switch Illumination Circuit

DESCRIPTION

The illuminated entry system controls the engine switch illumination.

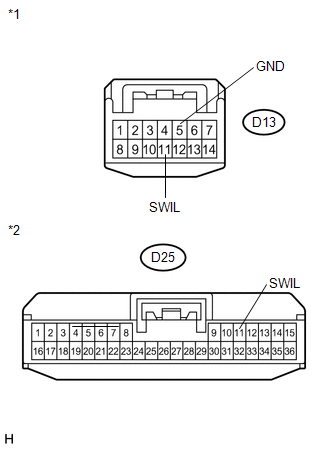

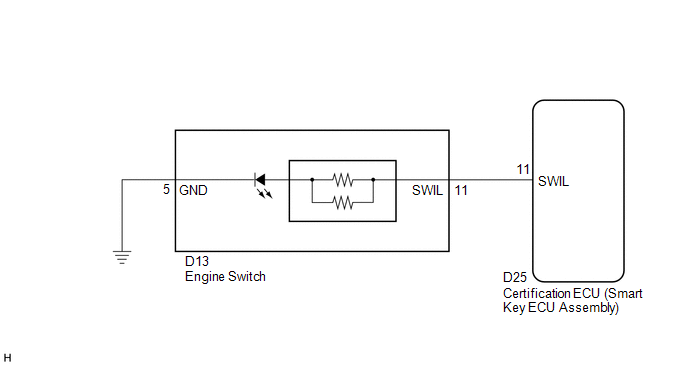

WIRING DIAGRAM

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Active Test.

(e) Check that the illumination operates.

Smart Key|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Power/Engine SW Light |

Engine switch illumination |

ON/OFF |

- |

OK:

Engine switch illumination comes on.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

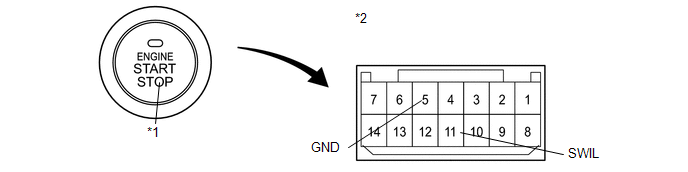

INSPECT ENGINE SWITCH |

(a) Remove the engine switch (See page .gif) ).

).

(b) Apply battery voltage to the engine switch.

(c) Check that the illumination comes on.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 11 (SWIL) Battery negative (-) → Terminal 5 (GND) |

Engine switch illumination comes on |

|

*1 |

Illumination |

*2 |

Component without harness connected (Engine Switch) |

| NG | .gif) |

REPLACE ENGINE SWITCH |

|

|

3. |

CHECK HARNESS AND CONNECTOR (ENGINE SWITCH - CERTIFICATION ECU AND BODY GROUND) |

|

(a) Disconnect the D25 certification ECU (smart Key ECU Assembly) connector. |

|

(b) Disconnect the D13 engine switch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D13-11 (SWIL) - D25-11 (SWIL) |

Always |

Below 1 Ω |

|

D13-5 (GND) - Body ground |

Always |

Below 1 Ω |

|

D13-11 (SWIL) - Body ground |

Always |

10 kΩ or higher |

|

*1 |

Front view of wire harness connector (to Engine Switch) |

|

*2 |

Front view of wire harness connector (to Certification ECU (Smart Key ECU Assembly)) |

| OK | .gif) |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Interior Light Auto Cut Circuit

Interior Light Auto Cut Circuit

DESCRIPTION

When battery saving control operates while the interior lights are on, the main

body ECU (driver side junction block assembly) opens the DOME CUT relay to turn

off the lights.

WIRING ...

Interior Light Power Source Circuit

Interior Light Power Source Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls operation of

the DOME CUT relay in order to supply power to the interior lights.

WIRING DIAGRAM

CAUTION / NOTICE / H ...

Other materials about Toyota Venza:

Terminals Of Ecu

TERMINALS OF ECU

NOTICE:

Turn the ignition switch off before measuring the resistances between

CAN bus main wires and between CAN bus branch wires.

Turn the ignition switch off before inspecting CAN bus wires for a ground

short.

After ...

Inspection

INSPECTION

PROCEDURE

1. INSPECT SPIRAL CABLE

(a) Visually check for defects with the spiral cable removed from the vehicle.

(1) The defects are as follows:

Scratches on the spiral cable

Small cracks the spiral cable

Dents on the spiral cabl ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL POWER SEAT SWITCH

(a) Install the power seat switch with the 3 screws.

(b) Connect the connector.

2. INSTALL FRONT SEAT CUSHION SHIELD ASSEMBLY

3. INSTALL SLID ...

0.1257

.gif)