Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR PULLEY WITH CLUTCH

|

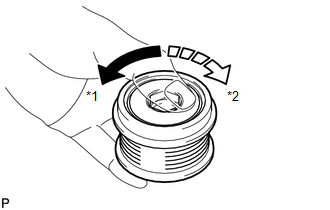

(a) Hold the center of the pulley, and confirm that the outer ring turns counterclockwise and does not turn clockwise. Text in Illustration

If the result is not as specified, replace the generator pulley with clutch. |

|

2. INSPECT GENERATOR DRIVE END FRAME BEARING

|

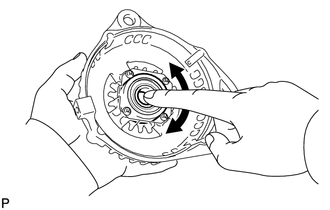

(a) Check that the bearing is not rough or worn and that it rotates smoothly. OK: The bearing rotates smoothly. If the bearing does not rotate smoothly, replace the bearing. |

|

3. INSPECT GENERATOR BRUSH HOLDER ASSEMBLY

|

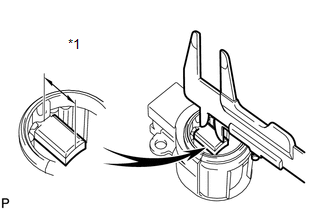

(a) Using a vernier caliper, measure the brush length. Text in Illustration

Standard length: 9.5 to 11.5 mm (0.374 to 0.453 in.) Minimum length: 4.5 mm (0.177 in.) If the brush length is less than the minimum, replace the generator brush holder assembly. |

|

4. INSPECT GENERATOR ROTOR ASSEMBLY

|

(a) Check that the generator rotor bearing is not rough or worn. If the result is not as specified, replace the generator rotor assembly. |

|

|

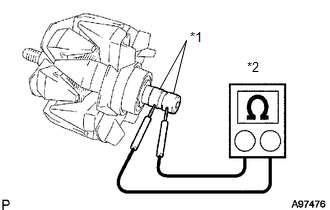

(b) Check the rotor for an open circuit. Text in Illustration

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

|

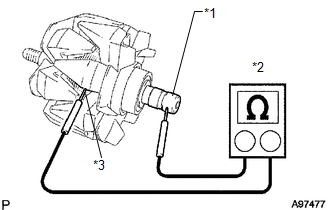

(c) Check if the rotor is grounded. Text in Illustration

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the generator rotor assembly. |

|

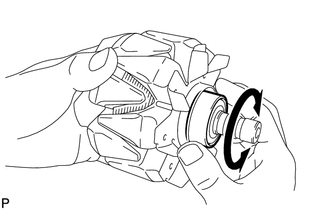

(d) Check the slip ring diameter.

|

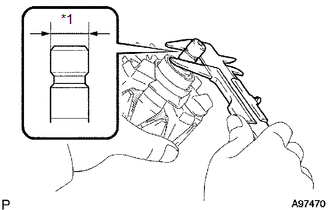

(1) Using a vernier caliper, measure the diameter of each slip ring. Text in Illustration

Standard diameter: 14.2 to 14.4 mm (0.559 to 0.567 in.) Minimum diameter: 14 mm (0.551 in.) If the diameter is less than the minimum, replace the generator rotor assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR PULLEY CAP

(a) Using a screwdriver, puncture the center of the generator pulley

cap and pry it off.

NOTICE:

Do not reuse the generator ...

Reassembly

Reassembly

REASSEMBLY

PROCEDURE

1. INSTALL GENERATOR ROTOR ASSEMBLY

(a) Place the generator drive end frame on the generator pulley.

(b) Install the ...

Other materials about Toyota Venza:

Control Module Communication Bus OFF (U0073/94,U0100/65,U0123/62,U0124/95,U0126/63)

DESCRIPTION

The skid control ECU receives the signals from the ECM, steering angle sensor,

and yaw rate and acceleration sensor via the CAN communication system.

DTC Code

DTC Detection Condition

Trouble Area

...

Open in Occupant Classification ECU Battery Positive Line (B1794)

DESCRIPTION

This circuit consists of the occupant classification ECU and power source circuit

(battery, fuse and wire harness).

DTC B1794 is recorded when a malfunction is detected in the occupant classification

ECU or power source circuit.

HINT:

If DT ...

Front Crankshaft Oil Seal

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT WHEEL RH

2. REMOVE NO. 1 ENGINE UNDER COVER

3. SEPARATE FRONT FENDER LINER RH

4. REMOVE FRONT FENDER APRON SEAL RH

5. REMOVE V-RIBBED BELT

6. REMOVE CRANKSHAFT ...

0.166