Toyota Venza: Disassembly

DISASSEMBLY

PROCEDURE

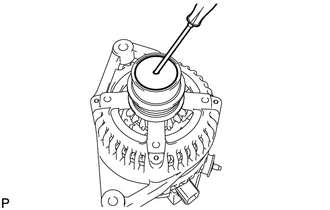

1. REMOVE GENERATOR PULLEY CAP

|

(a) Using a screwdriver, puncture the center of the generator pulley cap and pry it off. NOTICE: Do not reuse the generator pulley cap. |

|

2. REMOVE GENERATOR PULLEY WITH CLUTCH

|

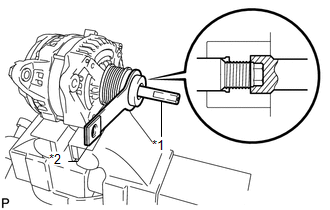

(a) Mount the generator in a vise. Text in Illustration

|

|

(b) Install SST (A) and (B) to the pulley as shown in the illustration.

SST: 09820-63021

|

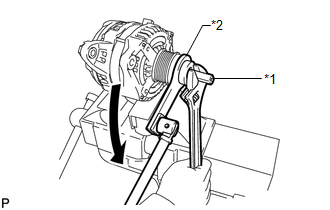

(c) Use a wrench to hold SST (A), and turn SST (B) counterclockwise to loosen the generator pulley. Text in Illustration

NOTICE:

|

|

(d) Remove the generator pulley.

3. REMOVE GENERATOR REAR END COVER

(a) Place the generator on the generator pulley.

|

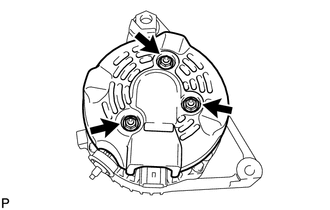

(b) Remove the 3 nuts and generator rear end cover. |

|

|

(c) Remove the terminal insulator. |

|

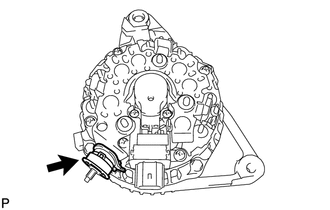

4. REMOVE GENERATOR BRUSH HOLDER ASSEMBLY

|

(a) Remove the 2 screws and generator brush holder. |

|

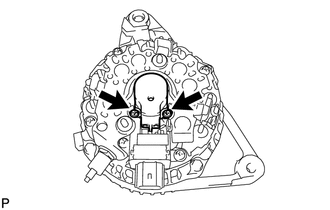

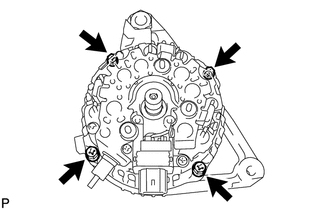

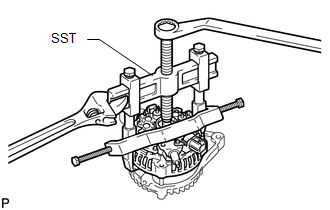

5. REMOVE GENERATOR COIL ASSEMBLY

|

(a) Remove the 4 bolts. |

|

|

(b) Using SST, remove the generator coil. SST: 09950-40011 09951-04020 09952-04010 09953-04020 09954-04010 09955-04071 09957-04010 |

|

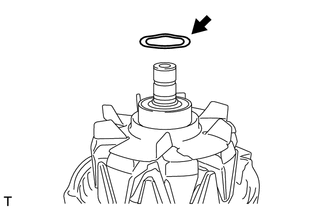

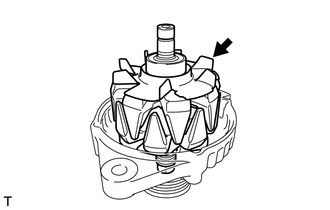

6. REMOVE GENERATOR ROTOR ASSEMBLY

|

(a) Remove the generator washer. |

|

|

(b) Remove the generator rotor assembly. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. RE ...

Inspection

Inspection

INSPECTION

PROCEDURE

1. INSPECT GENERATOR PULLEY WITH CLUTCH

(a) Hold the center of the pulley, and confirm that the outer ring turns

counterclockwise and does not turn clockwise.

...

Other materials about Toyota Venza:

Console Box Light

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

4. RE ...

Removal

REMOVAL

PROCEDURE

1. REMOVE PARKING BRAKE PEDAL ASSEMBLY

HINT:

Refer to the instructions for Removal of the parking brake pedal assembly (See

page ).

2. REMOVE NO. 1 PARKING BRAKE CABLE ASSEMBLY

(a) Remove the clip.

...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

0.1294