Toyota Venza: Hydraulic Test

HYDRAULIC TEST

1. PERFORM HYDRAULIC TEST

(a) Measure the line pressure.

CAUTION:

The line pressure test should always be carried out with at least 2 people. One person should observe the condition of wheels and wheel chocks while the other is performing the test.

NOTICE:

- Perform a test at the normal operating Automatic Transmission Fluid (ATF) temperature: 50 to 80°C (122 to 176°F)

- Be careful to prevent the SST hose from interfering with the exhaust pipe.

- This check must be conducted after checking and confirming that the engine is normal.

- Perform the test with the A/C off.

- Do not perform the stall test for longer than 5 seconds.

- When performing the stall speed test repeatedly, wait for 15 seconds or more between tests.

(1) Warm up the Automatic Transmission Fluid (ATF).

(2) Lift the vehicle up.

(3) Remove the engine under cover.

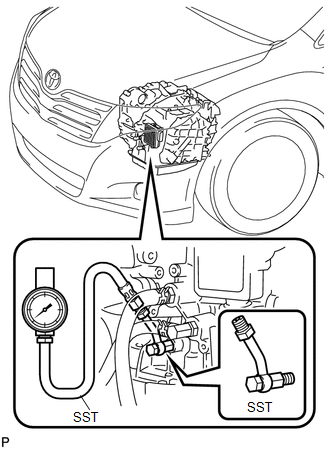

(4) Remove the test plug on the transaxle case front left side and install the SST.

SST: 09992-00095

09992-00231

09992-00271

(5) Lower the vehicle.

(6) Fully apply the parking brake and chock the 4 wheels.

(7) Connect the Techstream to the DLC3.

(8) Start the engine.

(9) Enter the following menus: Powertrain / ECT / Active Test / Control the Shift Position.

(10) Move the shift lever to D, and then use the Techstream to hold 3rd gear using Active Test. Measure the line pressure while the engine is idling.

Specified Line Pressure|

Condition |

D Position kPa (kgf/cm2, psi) |

|---|---|

|

Idling |

360 to 430 kPa (3.7 to 4.4 kgf/cm2, 52 to 62 psi) |

(11) Turn the ignition switch off.

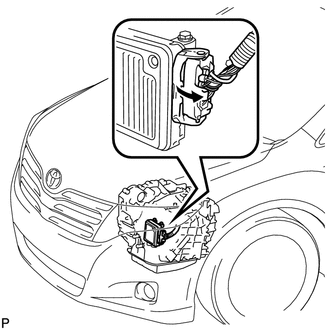

(12) Disconnect the connector of the TCM.

HINT:

Disconnect the connector only when performing the D position stall test.

(13) Start the engine.

(14) Firmly depress the brake pedal, move the shift lever to D, depress the accelerator pedal all the way down, and check the line pressure while the stall test is performed.

Specified Line Pressure|

Condition |

D Position kPa (kgf/cm2, psi) |

|---|---|

|

Stall test |

1160 to 1350 kPa (11.8 to 13.8 kgf/cm2, 168 to 196 psi) |

(15) Turn the ignition switch off.

(16) Connect the TCM connector, depress the brake pedal firmly, move the shift lever to R, and check that the line pressure while the engine is idling and during the stall test.

Specified Line Pressure|

Condition |

R Position kPa (kgf/cm2, psi) |

|---|---|

|

Idling |

800 to 950 kPa (8.2 to 9.7 kgf/cm2, 116 to 138 psi) |

|

Stall test |

1900 to 2200 kPa (19.4 to 22.4 kgf/cm2, 276 to 319 psi) |

(17) Remove the SST, install the test plug.

(18) Clear the DTCs.

Evaluation|

Test Result |

Possible Cause |

|---|---|

|

Measured values are higher than the specified value in all positions |

|

|

Measured values are lower than the specified value in all positions |

|

|

Pressure is low in D only |

|

|

Pressure is low in R only |

|

Road Test

Road Test

ROAD TEST

1. PROBLEM SYMPTOM CONFIRMATION

(a) Based on the result of the customer problem analysis, try to reproduce the

symptoms. If the problem is that the transaxle does not shift up, shift dow ...

Manual Shifting Test

Manual Shifting Test

MANUAL SHIFTING TEST

1. PERFORM MANUAL SHIFTING TEST

HINT:

Using this test, it can be determined whether a problem is in an electrical

circuit or if it is a mechanical problem in the tr ...

Other materials about Toyota Venza:

Back Door Closer does not Operate

DESCRIPTION

When the back door closer does not operate, one of the following may be the cause:

1) improper fit of the back door, or a foreign object is stuck in the back door

or 2) initialization of the power back door ECU (power back door motor unit)*1, ...

Disposal

DISPOSAL

PROCEDURE

1. DISPOSE OF REAR SHOCK ABSORBER

(a) Fully extend the shock absorber piston rod.

(b) Using a drill, make a hole in area B shown in the illustration to discharge

the gas inside. ...

Indicator Circuit

DESCRIPTION

The headlight beam level control system indicator light in the combination meter

assembly comes on for approximately 3 seconds when the ignition switch is turned

to ON. The indicator light also comes on when the headlight leveling ECU assembly ...

0.1479