Toyota Venza: Installation

INSTALLATION

PROCEDURE

1. INSTALL ROOF DRIP SIDE FINISH MOULDING CLIP (w/o Sliding Roof)

NOTICE:

- If reusing the clips, do not remove the double-sided tape remaining on the clips and where the clips will be installed on the body.

- If installing new clips, remove the double-sided tape remaining where the clips will be installed on the body and clean the body with a non-residue solvent.

|

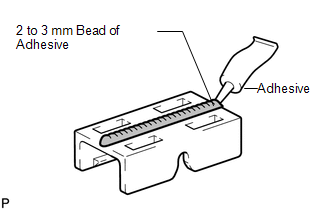

(a) Apply a 2 to 3 mm (0.0787 to 0.118 in.) bead of adhesive (3M DP-105 or equivalent) to new roof drip side finish moulding clips. HINT: Adhesive strength (tensile strength): 13.7 MPa (140 kgf/cm2) or more (when the temperature is 23°C (73°F).) |

|

(b) Press and install the 2 roof drip side finish moulding clips.

|

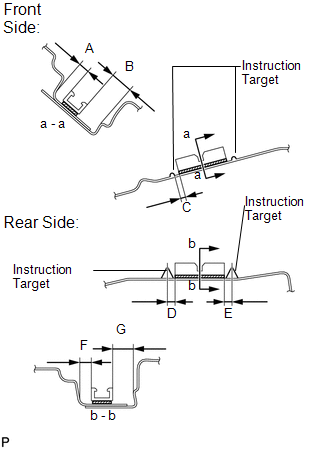

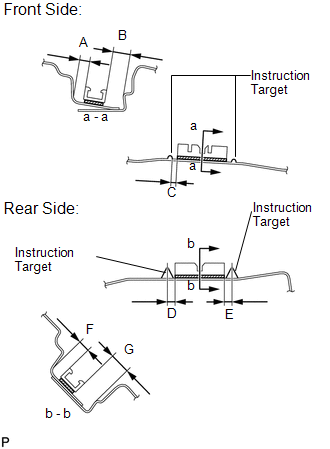

(c) Install the clips to the positions on the roof panel shown in the illustration. Determine the locations and firmly press and install the 2 roof drip side finish moulding clips after lightly applying adhesive (3M DP-105 or equivalent). Standard Dimension

|

|

(d) Install the roof drip center side finish moulding when 20 minutes or more have elapsed after pressing and installing the 2 roof drip side finish moulding clips.

HINT:

- Initial hardening time: 20 minutes

- Complete hardening time: 48 hours

2. INSTALL ROOF DRIP CENTER SIDE FINISH MOULDING (w/o Sliding Roof)

|

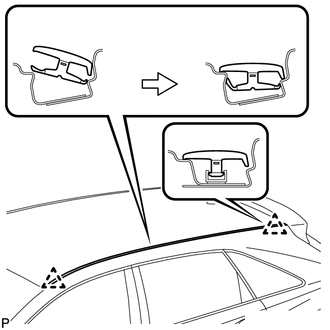

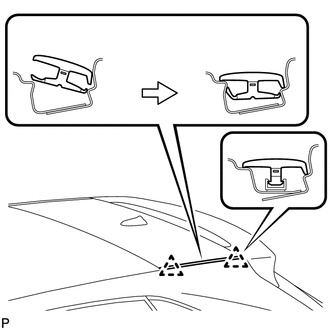

(a) Engage the 2 clips and install the roof drip center side finish moulding as shown in the illustration. |

|

3. INSTALL ROOF DRIP SIDE FINISH MOULDING CLIP (w/ Sliding Roof)

NOTICE:

- If reusing the clips, do not remove the double-sided tape remaining on the clips and where the clips will be installed on the body.

- If installing new clips, remove the double-sided tape remaining where the clips will be installed on the body and clean the body with a non-residue solvent.

|

(a) Apply a 2 to 3 mm (0.0787 to 0.118 in.) bead of adhesive (3M DP-105 or equivalent) to new roof drip side finish moulding clips. HINT: Adhesive strength (tensile strength): 13.7 MPa (140 kgf/cm2) or more (when the temperature is 23°C (73°F).) |

|

(b) Press and install the 2 roof drip side finish moulding clips.

|

(c) Install the clips to the positions on the roof panel shown in the illustration. Determine the locations and firmly press and install the 2 roof drip side finish moulding clips after lightly applying adhesive (3M DP-105 or equivalent). Standard Dimension

|

|

(d) Install the roof drip center side finish moulding when 20 minutes or more have elapsed after pressing and installing the 2 roof drip side finish moulding clips.

HINT:

- Initial hardening time: 20 minutes

- Complete hardening time: 48 hours

4. INSTALL ROOF DRIP CENTER SIDE FINISH MOULDING (w/ Sliding Roof)

|

(a) Engage the 2 clips and install the roof drip center side finish moulding as shown in the illustration. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. REMOVE ROOF DRIP CENTER SIDE FINISH MOULDING (w/o Sliding Roof)

(a) Put protective tape around the roof drip center side finish moulding.

Text in Illustration

...

Side Mudguard

Side Mudguard

...

Other materials about Toyota Venza:

Engine Coolant Temperature Circuit Malfunction (P0115,P0117,P0118)

DESCRIPTION

A thermistor, whose resistance value varies according to the engine coolant temperature,

is built into the engine coolant temperature sensor.

The structure of the sensor and its connection to the ECM are similar to those

of the intake air tem ...

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the engine assembly (See page

).

PROCEDURE

1. INSTALL ENGINE HANGERS

2. REMOVE ENGINE STAND

(a) Remove the engine stand.

3. INSTALL ENGINE WIRE

...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

HINT:

If a trouble code is displayed during the DTC check, inspect the trouble areas

listed for that code. For details of the code, refer to the following "See page".

Back Door Closer System

DTC Code

...

0.1712