Toyota Venza: Headlight Leveling ECU Power Source Circuit

DESCRIPTION

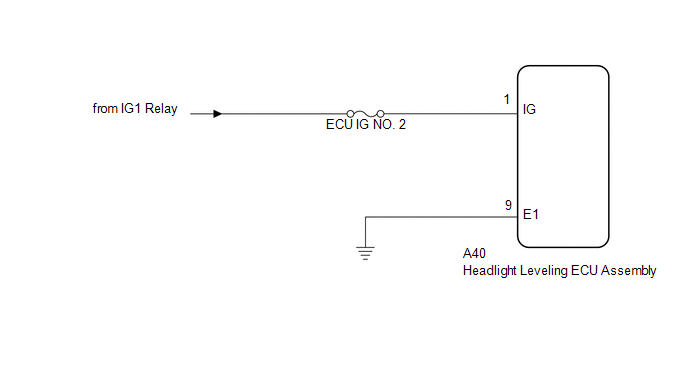

This circuit detects the state of the ignition switch, and sends it to the headlight leveling ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (BATTERY - HEADLIGHT LEVELING ECU ASSEMBLY) |

|

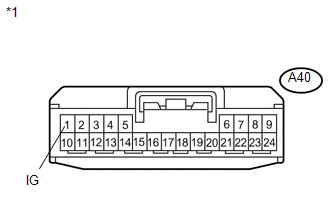

(a) Disconnect the A40 headlight leveling ECU assembly connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A40-1 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

A40-1 (IG) - Body ground |

Ignition switch off |

Below 1 V |

|

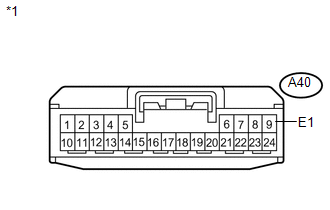

*1 |

Front view of wire harness connector (to Headlight Leveling ECU assembly) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING ECU ASSEMBLY - BODY GROUND) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

Headlight Beam Level Control Actuator Circuit

Headlight Beam Level Control Actuator Circuit

DESCRIPTION

The headlight leveling ECU assembly actuates the headlight leveling motor according

to vehicle conditions.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USING TECHS ...

Indicator Circuit

Indicator Circuit

DESCRIPTION

The headlight beam level control system indicator light in the combination meter

assembly comes on for approximately 3 seconds when the ignition switch is turned

to ON. The indicator ...

Other materials about Toyota Venza:

Lost Communication with ECM / PCM "A" (U0100)

DESCRIPTION

The engine control unit communicates with the TCM using the Controller Area Network

(CAN).

If there is a problem in this communication, the TCM sets a DTC.

DTC No.

DTC Detection Condition

Trouble Area

...

Intake Manifold Runner Control Circuit Low (Bank 1) (P2009,P2010)

DESCRIPTION

The ECM activates the DC motor for the tumble control valve, which opens and

closes the tumble control valve. The ECM activates the DC motor based on engine

speed, coolant temperature, intake air temperature and other conditions.

D ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR CENTER SEAT OUTER BELT ASSEMBLY

(a) Install the rear center seat outer belt assembly with the bolt and

nut.

Torque:

Bolt :

7.5 N·m {77 kgf·cm, 66 in·lbf}

Nut :

42 N·m {428 kgf·cm, ...

0.1296

.gif)