Toyota Venza: Headlight Beam Level Control Actuator Circuit

DESCRIPTION

The headlight leveling ECU assembly actuates the headlight leveling motor according to vehicle conditions.

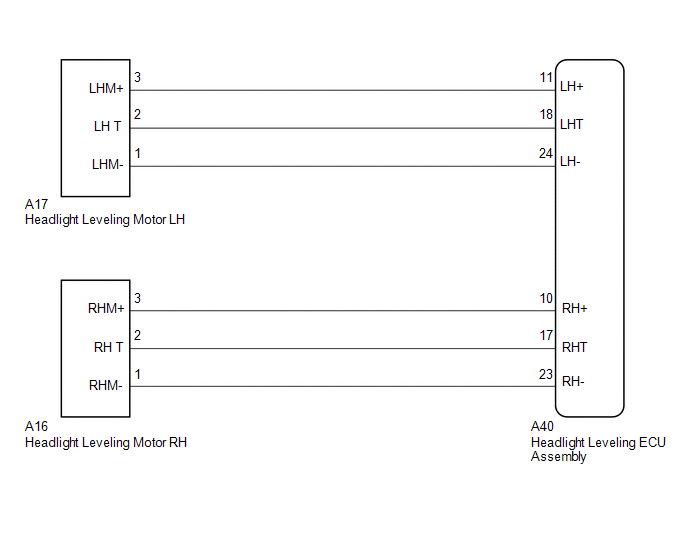

WIRING DIAGRAM

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / HL Auto Leveling / Active Test.

(e) Check that the motors operate.

HL Auto Leveling|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Drive The Leveling Motor |

Leveling motor |

UP/OFF |

- |

|

DOWN/OFF |

- |

OK:

Headlight leveling motors operate normally.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK HARNESS AND CONNECTOR (HEADLIGHT LEVELING MOTOR - HEADLIGHT LEVELING ECU ASSEMBLY) |

(a) Disconnect the A40 headlight leveling ECU connector.

(b) Disconnect the A17 or A16 headlight leveling motor connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

LH Side|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A40-18 (LHT) - A17-2 (LH T) |

Always |

Below 1 Ω |

|

A40-11 (LH+) - A17-3 (LHM+) |

Always |

Below 1 Ω |

|

A40-24 (LH-) - A17-1 (LHM-) |

Always |

Below 1 Ω |

|

A40-18 (LHT) - Body ground |

Always |

10 kΩ or higher |

|

A40-11 (LH+) - Body ground |

Always |

10 kΩ or higher |

|

A40-24 (LH-) - Body ground |

Always |

10 kΩ or higher |

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A40-17 (RHT) - A16-2 (RH T) |

Always |

Below 1 Ω |

|

A40-10 (RH+) - A16-3 (RHM+) |

Always |

Below 1 Ω |

|

A40-23 (RH-) - A16-1 (RHM-) |

Always |

Below 1 Ω |

|

A40-17 (RHT) - Body ground |

Always |

10 kΩ or higher |

|

A40-10 (RH+) - Body ground |

Always |

10 kΩ or higher |

|

A40-23 (RH-) - Body ground |

Always |

10 kΩ or higher |

|

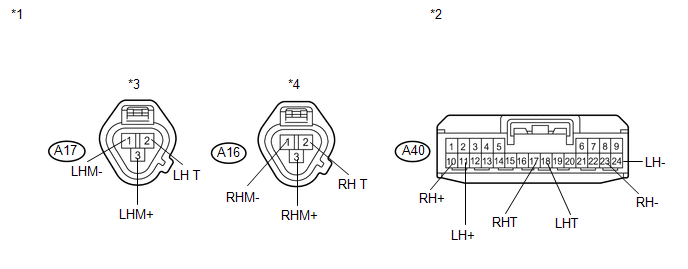

*1 |

Front view of wire harness connector (to Headlight Leveling Motor (Headlight Unit)) |

*3 |

LH Side |

|

*2 |

Front view of wire harness connector (to Headlight Leveling ECU Assembly) |

*4 |

RH Side |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

REPLACE HEADLIGHT LEVELING MOTOR (HEADLIGHT UNIT) |

(a) Temporarily replace the headlight leveling motor with a new or normally functioning

one (See page .gif) ).

).

(b) Perform the Active Test of the leveling motors.

OK:

Headlight leveling motors operate normally.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG | .gif) |

REPLACE HEADLIGHT LEVELING ECU ASSEMBLY |

Taillight Relay Circuit

Taillight Relay Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) controls the operation

of the TAIL relay.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits rel ...

Headlight Leveling ECU Power Source Circuit

Headlight Leveling ECU Power Source Circuit

DESCRIPTION

This circuit detects the state of the ignition switch, and sends it to the headlight

leveling ECU assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for ci ...

Other materials about Toyota Venza:

Camshaft Position "A" - Timing Over-Advanced or System Performance (Bank 1)

(P0011,P0012)

DESCRIPTION

Refer to DTC P0010 (See page ).

DTC No.

DTC Detection Condition

Trouble Area

P0011

The valve timing is stuck at a certain value when in the advance range

(1 trip detection logic).

...

Precaution

PRECAUTION

1. PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize

the following system after the cable is reconnected.

System Name

...

System Description

SYSTEM DESCRIPTION

1. TOUCH SWITCH OUTLINE

(a) Touch switches are touch-sensitive (interactive) switches operated by touching

the screen. When a switch is pressed, the outer film bends in to contact the inner

glass at the pressed position. By doing this, ...

0.1306

.gif)