Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

4. REMOVE V-RIBBED BELT

HINT:

See page .gif)

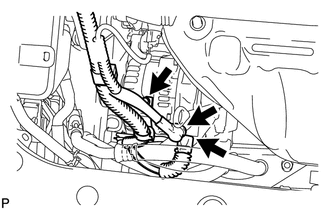

5. REMOVE WIRE HARNESS CLAMP BRACKET

(a) Detach the wire harness clamp from the clamp bracket.

(b) Remove the bolt and clamp bracket.

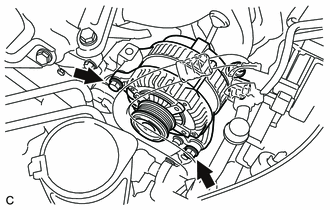

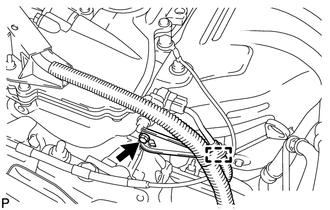

6. REMOVE GENERATOR ASSEMBLY

|

(a) Disconnect the generator connector. |

|

(b) Remove the terminal cap.

(c) Remove the nut and disconnect the generator wire.

(d) Remove the bolt and wire harness clamp bracket.

|

(e) Remove the 2 bolts and generator. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE GENERATOR PULLEY CAP

(a) Using a screwdriver, puncture the center of the generator pulley

cap and pry it off.

NOTICE:

Do not reuse the generator ...

Other materials about Toyota Venza:

Vehicle Speed Sensor "A" (P0500)

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU.

The skid control ECU converts these wheel speed signals into a 4-pulse signal

and outputs it to the ECM via the combination meter. The ECM det ...

Rear Speed Sensor RH Circuit (C0210/33,C0215/34,C1273/73,C1274/74,C1332/38,C1333/39)

DESCRIPTION

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ECU. These signals are used for the ABS control system.

Speed sensor rotors have rows of alternating N and S magnetic poles (for 2WD)

or 48 serrati ...

Intake Air Temperature Sensor Gradient Too High (P0111)

DESCRIPTION

The intake air temperature sensor, mounted on the mass air flow meter,

monitors the intake air temperature. The intake air temperature sensor has

a built-in thermistor with a resistance that varies according to the temperature

...

0.1635