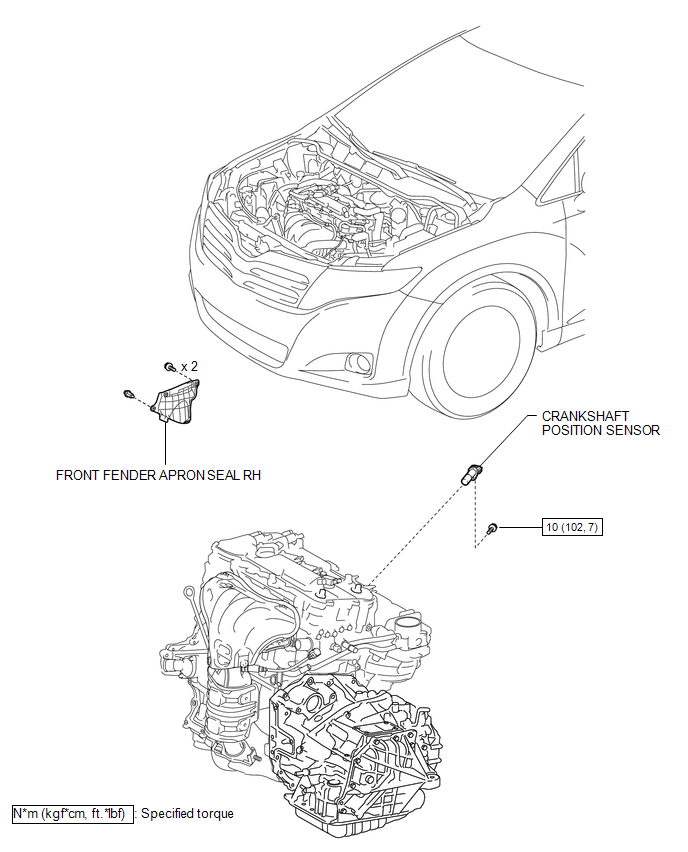

Toyota Venza: Crankshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT FENDER APRON SEAL RH

.gif)

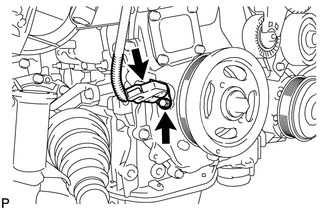

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

Inspection

INSPECTION

PROCEDURE

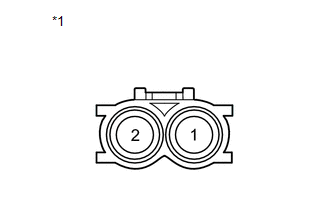

1. INSPECT CRANKSHAFT POSITION SENSOR

Text in Illustration

Text in Illustration

|

*1 |

Component without harness connected (Crank Position Sensor) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 - 2 |

Cold |

1630 to 2740 Ω |

|

Hot |

2065 to 3225 Ω |

HINT:

In the table above, the terms "Cold" and "Hot" refer to the temperature of the coils. "Cold" means approximately -10 to 50°C (14 to 122°F). "Hot" means approximately 50 to 100°C (122 to 212°F).

If the result is not as specified, replace the crankshaft position sensor.

Installation

INSTALLATION

PROCEDURE

1. INSTALL CRANKSHAFT POSITION SENSOR

(a) Apply a light coat of engine oil to the O-ring of the crankshaft position sensor.

NOTICE:

If reusing the crankshaft position sensor, be sure to inspect the O-ring.

(b) Install the crankshaft position sensor to the timing chain cover sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

- If the crankshaft position sensor has been struck or dropped, replace it.

- Make sure that the O-ring is not cracked or moved out of place when installing the crankshaft position sensor.

(c) Connect the crankshaft position sensor connector.

2. INSPECT FOR OIL LEAK

3. INSTALL FRONT FENDER APRON SEAL RH

.gif)

Camshaft Position Sensor

Camshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT POSITION SENSOR (for Exhaust Side)

(a) Apply a light coat of engine oil to the O-ring of the cam ...

Ecm

Ecm

...

Other materials about Toyota Venza:

Abnormal Temperature Inside ID1 Tire (C2165/65-C2168/68)

DESCRIPTION

Each tire pressure warning valve and transmitter measures the tire internal temperature

as well as tire pressure, and transmits the information to the tire pressure warning

ECU along with the transmitter ID. If the measured temperature is out ...

Terminals Of Ecu

TERMINALS OF ECU

1. COMBINATION METER ASSEMBLY

(a) Measure the voltage and resistance according to the value(s) in the table

below.

Terminal No. (Symbol)

Wiring Color

Terminal Description

Condition

...

HD Radio Tuner Malfunction (B1551,B15A0,B15AD,B15B0,B15B3,B15B4,B15B7)

DESCRIPTION

These DTCs are stored when a malfunction occurs in the navigation receiver assembly.

DTC No.

DTC Detection Condition

Trouble Area

B1551

When any of the following conditions is met:

...

0.1593