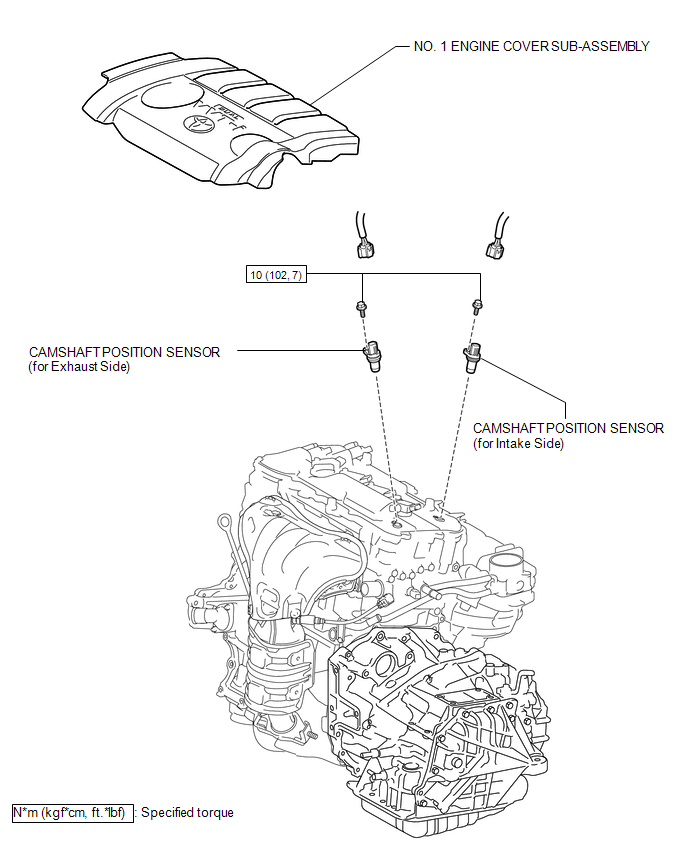

Toyota Venza: Camshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

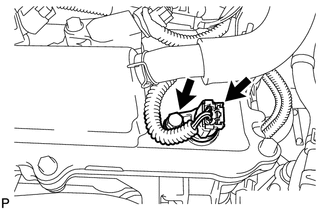

1. INSTALL CAMSHAFT POSITION SENSOR (for Exhaust Side)

(a) Apply a light coat of engine oil to the O-ring of the camshaft position sensor.

NOTICE:

If reusing the camshaft position sensor, be sure to inspect the O-ring.

(b) Install the camshaft position sensor to the cylinder head cover sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

- If the camshaft position sensor has been struck or dropped, replace it.

- Make sure that the O-ring is not cracked or moved out of place when installing the camshaft position sensor.

(c) Connect the camshaft position sensor connector.

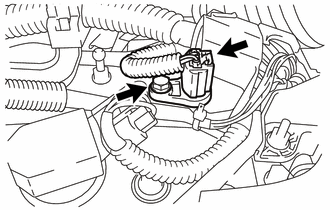

2. INSTALL CAMSHAFT POSITION SENSOR (for Intake Side)

(a) Apply a light coat of engine oil to the O-ring of the camshaft position sensor.

NOTICE:

If reusing the camshaft position sensor, be sure to inspect the O-ring.

(b) Install the camshaft position sensor with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

- If the camshaft position sensor has been struck or dropped, replace it.

- Make sure that the O-ring is not cracked or moved out of place when installing the camshaft position sensor.

(c) Connect the camshaft position sensor connector.

3. INSPECT FOR OIL LEAK

4. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

Removal

REMOVAL

PROCEDURE

1. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

2. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

3. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

(a) Disconnect the sensor connector.

(b) Remove the bolt and sensor.

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (for Exhaust Side)

(a) Apply a light coat of engine oil to a new O-ring, and install it

to the oil contro ...

Crankshaft Position Sensor

Crankshaft Position Sensor

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE FRONT FENDER APRON SEAL RH

2. REMOVE CRANKSHAFT POSITION SENSOR

(a) Disconnect the sensor connector.

(b) Remo ...

Other materials about Toyota Venza:

Main Body Ecu

Components

COMPONENTS

ILLUSTRATION

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER INSTRUMENT PANEL

HINT:

Refer to the procedure up to Remove Upper Instrument Panel Sub-assembly (See

page ).

2. REMOVE MAIN BODY ECU (DRIVER SIDE JUNCTION BLOCK ASSEM ...

Test Mode Procedure

TEST MODE PROCEDURE

1. ENTER TEST MODE (SIGNAL CHECK MODE)

(a) Turn the ignition switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Check that the tire pressure warning light comes on for 3 seconds and then

goes ...

Dtc Check / Clear

DTC CHECK / CLEAR

1. CHECK DTC

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Starting Control or Power Source

Control / Trouble Codes.

(e) Read t ...

0.1547