Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT STARTER ASSEMBLY

NOTICE:

These tests must be performed within 3 to 5 seconds to avoid burning out the coil.

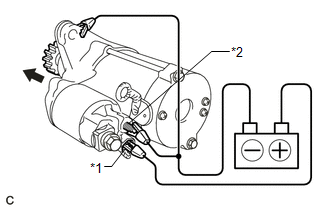

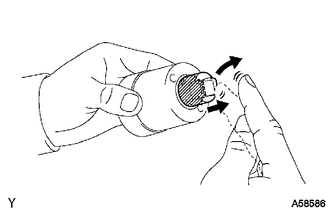

(a) Perform a pull-in test.

(1) Remove the nut and disconnect the lead wire from terminal C.

|

(2) Connect the battery to the magnetic switch as shown in the illustration. Check that the clutch pinion gear extends. Text in Illustration

If the clutch pinion gear does not move, replace the magnetic switch assembly. |

|

|

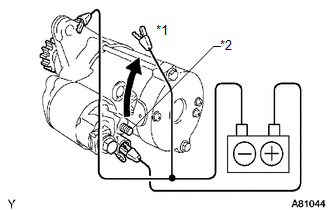

(b) Perform a hold-in test. (1) While maintaining the battery connections of the pull-in test above, disconnect the negative (-) lead from terminal C. Check that the pinion gear remains extended. Text in Illustration

If the clutch pinion gear returns inward, replace the magnetic switch assembly. |

|

|

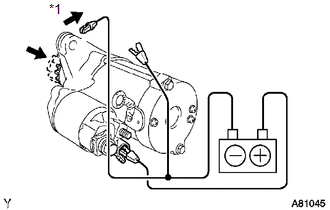

(c) Perform a clutch pinion gear return test. (1) Disconnect the negative (-) lead from the starter body. Check that the clutch pinion gear returns. If the clutch pinion gear does not return, replace the magnetic switch assembly. Text in Illustration

|

|

|

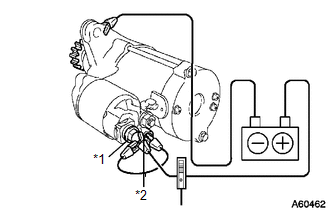

(d) Perform a no-load performance test. Text in Illustration

(1) Connect the lead wire to terminal C with the nut. Make sure that the lead is not grounded. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} (2) Clamp the starter in a vise. (3) Connect the battery and an ammeter to the starter as shown in the illustration. (4) Check that the starter rotates smoothly and steadily while the pinion gear is moving out. Then measure the current. Standard current: 90 A or less at 11.5 V If the result is not as specified, repair or replace the starter assembly. |

|

2. INSPECT MAGNETIC SWITCH ASSEMBLY

|

(a) Check the plunger. (1) Push in the plunger and check that it returns quickly to its original position. If necessary, replace the magnetic switch assembly. |

|

|

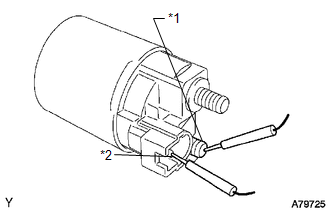

(b) Check if the pull-in coil has an open circuit. Text in Illustration

(1) Measure the resistance between terminals 50 and C. Standard resistance: Below 1 Ω If the result is not as specified, replace the magnetic switch assembly. |

|

|

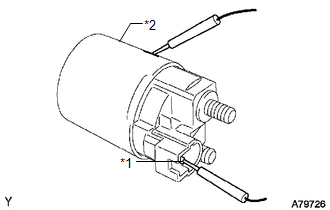

(c) Check if the hold-in coil has an open circuit. Text in Illustration

(1) Measure the resistance between terminal 50 and the switch body. Standard resistance: Below 2 Ω If the result is not as specified, replace the magnetic switch assembly. |

|

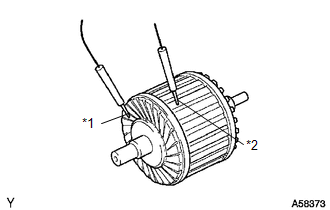

3. INSPECT STARTER ARMATURE ASSEMBLY

HINT:

If these is no continuity between any segments, replace the starter armature assembly.

(a) Check the commutator for contamination and burns on its surface.

If the surface is dirty or burnt, correct it with sandpaper (No. 400) or a lathe.

|

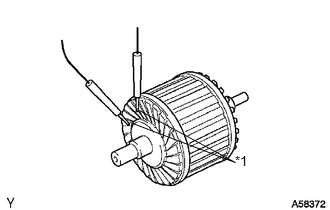

(b) Check if the commutator has an open circuit. Text in Illustration

(1) Measure the resistance between the segments of the commutator. Standard resistance: Below 1 Ω If the result is not as specified, replace the armature assembly. |

|

|

(c) Check if the commutator is grounded. Text in Illustration

(1) Measure the resistance between the commutator and armature coil core. Standard resistance: 10 kΩ or higher If the result is not as specified, replace the armature assembly. |

|

|

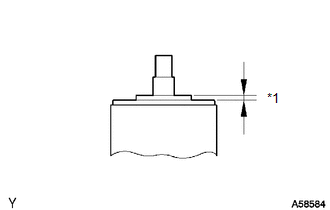

(d) Using a vernier caliper, measure the commutator length. Text in Illustration

Standard length: 3.1 to 3.8 mm (0.122 to 0.149 in.) Maximum length: 3.8 mm (0.149 in.) If the length is greater than the maximum, replace the starter armature assembly. |

|

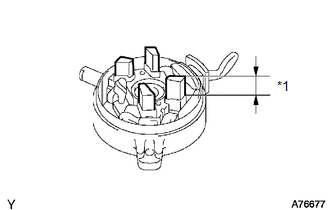

4. INSPECT STARTER COMMUTATOR END FRAME ASSEMBLY

|

(a) Using a vernier caliper, measure the brush length. Text in Illustration

Standard length: 4.0 to 9.0 mm (0.158 to 0.354 in.) Minimum length: 4.0 mm (0.158 in.) If the length is less than the minimum, replace the end frame assembly. |

|

|

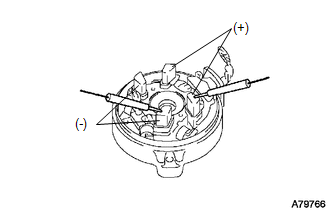

(b) Check the brush insulation. (1) Measure the resistance between the positive (+) and negative (-) brushes. Standard resistance: 10 kΩ or higher If the result is not as specified, replace the end frame assembly. |

|

5. INSPECT STARTER CLUTCH

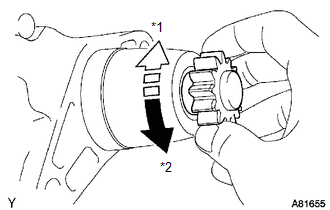

Text in Illustration

(a) Rotate the clutch pinion gear counterclockwise and check that it turns freely. Try to rotate the clutch pinion gear clockwise and check that it locks. If necessary, replace the starter drive housing assembly. |

|

Disassembly

Disassembly

DISASSEMBLY

PROCEDURE

1. REMOVE MAGNETIC SWITCH ASSEMBLY

(a) Remove the nut and disconnect the lead wire from the magnetic switch.

...

Reassembly

Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use high-temperature grease to lubricate the bearings, gears and return spring

when assembling the starter.

PROCEDURE

1. INSTALL PLANETARY GEAR

...

Other materials about Toyota Venza:

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Check For Intermittent Problems

CHECK FOR INTERMITTENT PROBLEMS

HINT:

Inspect the ECM using check mode. Intermittent problems are easier to detect

with the Techstream when the ECM is in check mode. In check mode, the ECM uses 1

trip detection logic, which is more sensitive to malfuncti ...

Power Back Door Warning System does not Operate

DESCRIPTION

When the power back door warning system does not operate, one of the following

may be malfunctioning: 1) power back door warning buzzer circuit, 2) wireless door

lock control system or 3) power back door ECU.

WIRING DIAGRAM

CAUTION / NOTIC ...

0.1548