Toyota Venza: Inspection

INSPECTION

PROCEDURE

1. INSPECT INTAKE AIR CONTROL VALVE (for ACIS)

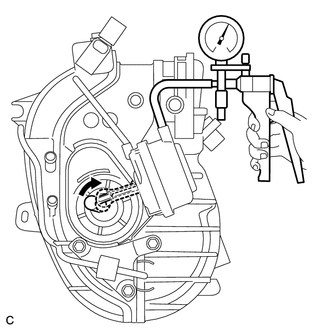

(a) Inspect the diaphragm.

|

(1) Using a vacuum pump, apply a vacuum of 60 kPa (450 mmHg, 17.7 in.Hg) or higher to the diaphragm chamber. Wait for 1 minute and check that the needle of the vacuum pump does not lower. If the result is not as specified, replace the intake manifold. |

|

(b) After applying vacuum in the step above, check that the actuator rod operates.

2. INSPECT VACUUM TANK AND CHECK VALVE

|

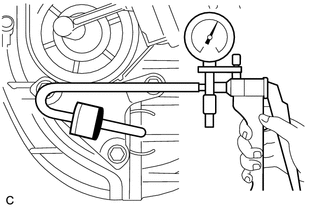

(a) Disconnect the vacuum hose from the check valve. |

|

(b) Using a vacuum pump, apply vacuum to the check valve. Wait for 1 minute and check that the needle of the vacuum pump does not lower.

If the result is not as specified, replace the check valve.

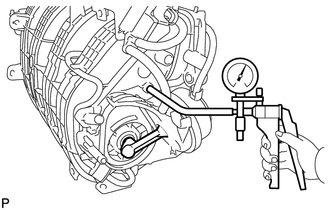

(c) Connect the vacuum hose to the check valve.

|

(d) Using a vacuum pump, apply a vacuum of 60 kPa (450 mmHg, 17.7 in.Hg) or higher to the vacuum tank. Wait for 1 minute and check that the needle of the vacuum pump does not lower. If the result is not as specified, replace the intake manifold. |

|

Removal

Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

(See page ).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

CAUTION:

When disconnecting the cable, some systems need to be initial ...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSTALL ENGINE MOUNTING DAMPER

(a) Install the engine mounting damper with the 3 bolts.

Torque:

9.0 N·m {92 kgf·cm, 80 in·lbf}

...

Other materials about Toyota Venza:

Moon roof

Use the overhead switches to open, close, and tilt the moon roof up and down.

- Opening and closing

1. Open

The moon roof stops slightly before the fully open position to reduce wind noise.

Move the switch backward again to fully open.

2. Close ( ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT WINDSHIELD WIPER MOTOR ASSEMBLY

(a) for RH Side

(1) Operate the windshield wiper motor assembly.

(2) Stop the windshield wiper motor assembly operation.

...

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

CAUTION:

Be sure to follow the correct removal and installation procedures of the rear

airbag sensor.

PROCEDURE

1. INSPECT REAR AIRBAG SENSOR (VEHICLE NOT INVOLVED IN COLLISION)

(a) Perform a diagnostic sys ...

0.1483