Toyota Venza: Charge Warning Light Comes ON while Driving

PROCEDURE

|

1. |

CHECK LOCK FUNCTION OF CLUTCH PULLEY |

(a) Check the lock function with the pulley installed in the vehicle.

(1) Visually check that the rotor in the generator operates with the engine started.

(b) Check the lock function with the pulley removed from the vehicle.

(1) Remove the generator pulley cap.

|

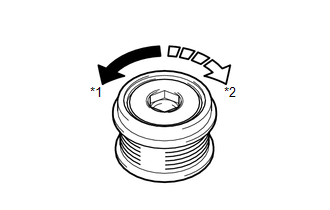

(2) Hold the generator rotor using SST, and turn the clutch pulley clockwise

to check that the outer ring locks (See page

Text in Illustration

OK: The outer ring locks. |

|

SST: 09820-63021

| NG | .gif) |

REPLACE CLUTCH PULLEY |

|

|

2. |

CHECK LOCK OF CLUTCH PULLEY |

(a) Start the engine and visually check for looseness of the clutch pulley.

OK:

The clutch pulley is not loose.

| OK | .gif) |

REPLACE GENERATOR ASSEMBLY |

| NG | .gif) |

TIGHTEN CLUTCH PULLEY TO THE SPECIFIED TORQUE |

Problem Symptoms Table

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in o ...

Noise Occurs from Generator while Engine is Running

Noise Occurs from Generator while Engine is Running

PROCEDURE

1.

CHECK LOOSENESS OF V-RIBBED BELT

(a) Check the tension of the belt by pushing it down with a finger.

OK:

The tension of the belt is enough.

NG ...

Other materials about Toyota Venza:

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Fail-safe Chart

FAIL-SAFE CHART

1. FAIL-SAFE FUNCTION

If the following malfunctions occur, the AWD control ECU will stop the

function of 4WD control system or partly change the function to control

the system.

If a malfunction occurs in the senso ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL OUTER REAR VIEW MIRROR ASSEMBLY

(a) Engage the 3 claws to install the outer rear view mirror assembly

as shown in the illustration.

(b) Install the 3 nuts.

Tor ...

0.1135

.gif) ).

).

.gif)