Toyota Venza: Front Sensor Communication Malfunction (C1AEC)

DESCRIPTION

This DTC is stored when there is an open or short circuit in the communication line between the front sensors and the ECU, or when there is a malfunction in a front sensor.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

C1AEC |

An open or short circuit in the communication line between the front sensors and ECU or a malfunction in a front sensor during initialization mode after the engine switch is turned on (IG). |

|

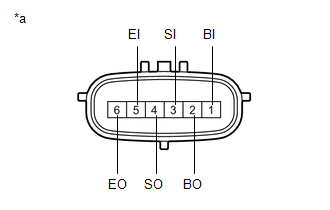

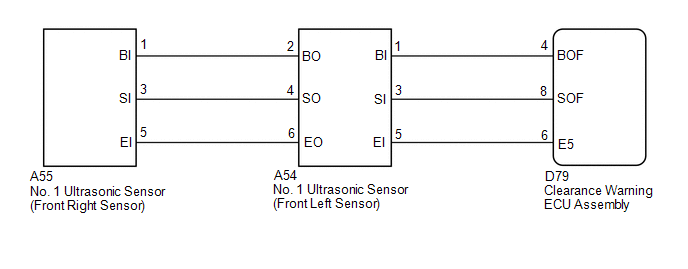

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK DTC OUTPUT (C1AEC) |

(a) Check for DTCs (See page .gif) ).

).

(b) Clear the DTCs (See page .gif) ).

).

(c) Recheck for DTCs (See page .gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC C1AEC is output |

A |

|

No DTCs are output |

B |

| B | .gif) |

USE SIMULATION METHOD TO CHECK |

|

|

2. |

CHECK HARNESS AND CONNECTOR (CLEARANCE WARNING ECU ASSEMBLY - FRONT LEFT SENSOR) |

(a) Disconnect the D79 clearance warning ECU assembly connector.

(b) Disconnect the A54 No. 1 ultrasonic sensor connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D79-4 (BOF) - A54-1 (BI) |

Always |

Below 1 Ω |

|

D79-8 (SOF) - A54-3 (SI) |

Always |

Below 1 Ω |

|

D79-6 (E5) - A54-5 (EI) |

Always |

Below 1 Ω |

|

D79-4 (BOF) - Body ground |

Always |

10 kΩ or higher |

|

D79-8 (SOF) - Body ground |

Always |

10 kΩ or higher |

|

D79-6 (E5) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (FRONT LEFT SENSOR - FRONT RIGHT SENSOR) |

(a) Disconnect the A55 No. 1 ultrasonic sensor connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A54-2 (BO) - A55-1 (BI) |

Always |

Below 1 Ω |

|

A54-4 (SO) - A55-3 (SI) |

Always |

Below 1 Ω |

|

A54-6 (EO) - A55-5 (EI) |

Always |

Below 1 Ω |

|

A54-2 (BO) - Body ground |

Always |

10 kΩ or higher |

|

A54-4 (SO) - Body ground |

Always |

10 kΩ or higher |

|

A54-6 (EO) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT NO. 1 ULTRASONIC SENSOR (FRONT LEFT SENSOR) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPLACE NO. 1 ULTRASONIC SENSOR (FRONT LEFT SENSOR) |

|

|

5. |

REPLACE NO. 1 ULTRASONIC SENSOR (FRONT LEFT SENSOR) |

.gif)

|

|

6. |

CHECK DTC OUTPUT (C1AEC) |

(a) Clear the DTCs (See page .gif) ).

).

(b) Check for DTCs (See page .gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC C1AEC is output |

A |

|

No DTCs are output |

B |

| B | .gif) |

END |

|

|

7. |

REPLACE NO. 1 ULTRASONIC SENSOR (FRONT RIGHT SENSOR) |

.gif)

|

|

8. |

CHECK DTC OUTPUT (C1AEC) |

(a) Clear the DTCs (See page .gif) ).

).

(b) Check for DTCs (See page .gif) ).

).

|

Result |

Proceed to |

|---|---|

|

DTC C1AEC is output |

A |

|

No DTCs are output |

B |

| A | .gif) |

REPLACE CLEARANCE WARNING ECU ASSEMBLY |

| B | .gif) |

END |

Lost Communication with ECM / PCM "A" (U0100-U0142,U0155)

Lost Communication with ECM / PCM "A" (U0100-U0142,U0155)

DESCRIPTION

These DTCs are stored when the clearance warning ECU assembly cannot receive

and recognize several signals via the CAN communication system.

DTC No.

DTC Detection ...

Rear Sensor Communication Malfunction (C1AED)

Rear Sensor Communication Malfunction (C1AED)

DESCRIPTION

This DTC is stored when there is an open or short circuit in the communication

line between the rear sensors and the ECU, or when there is a malfunction in a rear

sensor.

...

Other materials about Toyota Venza:

Washer Level Warning Switch

Components

COMPONENTS

ILLUSTRATION

Inspection

INSPECTION

PROCEDURE

1. INSPECT LEVEL WARNING SWITCH ASSEMBLY

HINT:

The following check should be performed with the windshield washer motor and

pump installed to the washer jar.

(a) Fill the washe ...

Mass Air Flow Circuit Range / Performance Problem (P0101)

DESCRIPTION

Refer to DTC P0102 (See page ).

DTC No.

DTC Detection Condition

Trouble Area

P0101

All of the following conditions are met (2 trip detection logic):

(a) The engine is running.

(b ...

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

0.152

.gif)