Toyota Venza: VC Output Circuit

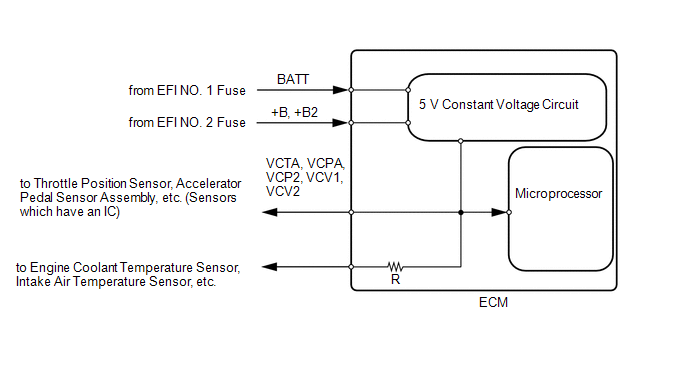

DESCRIPTION

The ECM constantly generates 5 V of power from battery voltage supplied to the +B (BATT) terminal to operate the microprocessor. The ECM also provides this power to the sensors through the VC output circuit.

When the VC circuit is short-circuited, the microprocessor in the ECM and sensors that are supplied with power through the VC circuit are inactivated because the power is not supplied from the VC circuit. Under this condition, the system does not start up and the MIL does not illuminate even if the system malfunctions.

HINT:

Under normal conditions, the MIL is illuminated when the ignition switch is turned to ON. The MIL turns off when the engine is started.

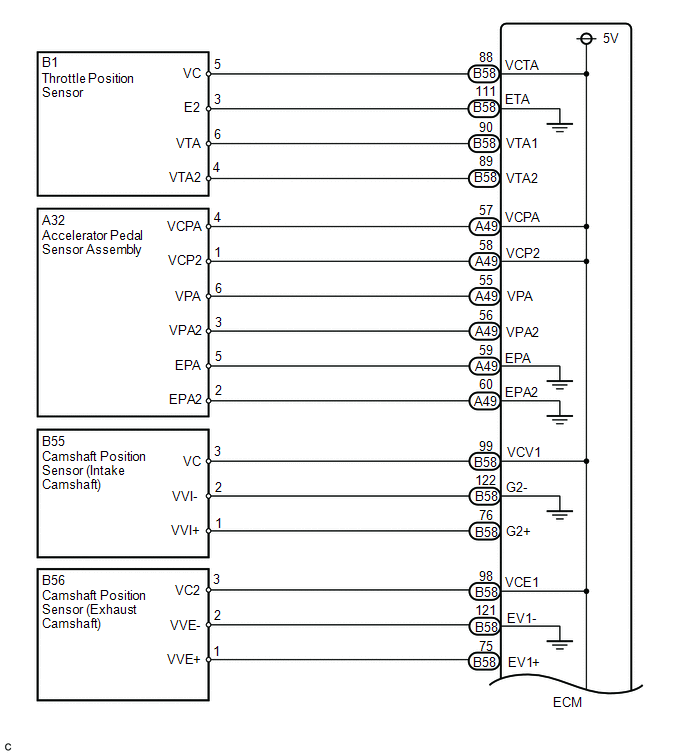

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK MIL |

(a) Check that the Malfunction Indicator Lamp (MIL) turns on when turning the ignition switch to ON.

OK:

MIL turns on.

| OK | .gif) |

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK COMMUNICATION BETWEEN TECHSTREAM AND ECM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B | .gif) |

GO TO MIL CIRCUIT |

|

|

3. |

CHECK MIL (THROTTLE POSITION SENSOR) |

(a) Disconnect the throttle body connector.

(b) Turn the ignition switch to ON.

(c) Check the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL does not illuminate |

A |

|

MIL illuminates |

B |

HINT:

Perform "Inspection After Repair" after replacing the throttle body (See page

.gif) ).

).

| B | .gif) |

REPLACE THROTTLE BODY |

|

|

4. |

CHECK MIL (ACCELERATOR PEDAL SENSOR ASSEMBLY) |

(a) Disconnect the accelerator pedal sensor assembly connector.

(b) Turn the ignition switch to ON.

(c) Check the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL does not illuminate |

A |

|

MIL illuminates |

B |

| B | .gif) |

REPLACE ACCELERATOR PEDAL SENSOR ASSEMBLY |

|

|

5. |

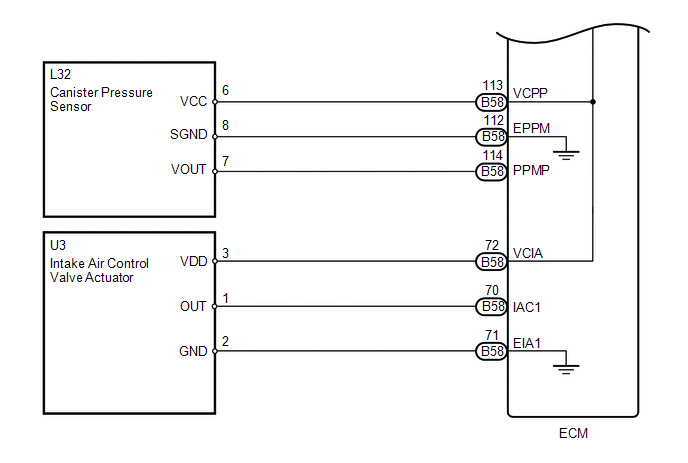

CHECK MIL (CANISTER PUMP MODULE) |

(a) Disconnect the canister pump module connector.

(b) Turn the ignition switch to ON.

(c) Check the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL does not illuminate |

A |

|

MIL illuminates |

B |

| B | .gif) |

REPLACE CHARCOAL CANISTER ASSEMBLY |

|

|

6. |

CHECK MIL (CAMSHAFT POSITION SENSOR (FOR INTAKE CAMSHAFT)) |

(a) Disconnect the camshaft position sensor (for intake camshaft) connector.

(b) Turn the ignition switch to ON.

(c) Check the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL does not illuminate |

A |

|

MIL illuminates |

B |

| B | .gif) |

REPLACE CAMSHAFT POSITION SENSOR |

|

|

7. |

CHECK MIL (CAMSHAFT POSITION SENSOR (FOR EXHAUST CAMSHAFT)) |

(a) Disconnect the camshaft position sensor (for exhaust camshaft) connector.

(b) Turn the ignition switch to ON.

(c) Check the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL does not illuminate |

A |

|

MIL illuminates |

B |

| B | .gif) |

REPLACE CAMSHAFT POSITION SENSOR |

|

|

8. |

CHECK MIL (INTAKE AIR CONTROL VALVE ACTUATOR) |

(a) Disconnect the intake air control valve actuator connector.

(b) Turn the ignition switch to ON.

(c) Check the MIL.

|

Result |

Proceed to |

|---|---|

|

MIL does not illuminate |

A |

|

MIL illuminates |

B |

| B | .gif) |

REPLACE INTAKE AIR CONTROL VALVE ACTUATOR |

|

|

9. |

CHECK HARNESS AND CONNECTOR (VC CIRCUIT) |

(a) Disconnect the throttle body connector.

(b) Disconnect the accelerator pedal sensor assembly connector.

(c) Disconnect the canister pump module connector.

(d) Disconnect the camshaft position sensor (for intake camshaft) connector.

(e) Disconnect the camshaft position sensor (for exhaust camshaft) connector.

(f) Disconnect the intake air control valve actuator connector.

(g) Disconnect the ECM connectors.

(h) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A49-57 (VCPA) - Body ground |

Always |

10 kΩ or higher |

|

A49-58 (VCP2) - Body ground |

Always |

10 kΩ or higher |

|

B58-72 (VCIA) - Body ground |

Always |

10 kΩ or higher |

|

B58-88 (VCTA) - Body ground |

Always |

10 kΩ or higher |

|

B58-98 (VCE1) - Body ground |

Always |

10 kΩ or higher |

|

B58-99 (VCV1) - Body ground |

Always |

10 kΩ or higher |

|

B58-113 (VCPP) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif) |

REPLACE ECM |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

ECM Power Source Circuit

ECM Power Source Circuit

DESCRIPTION

When the ignition switch is turned to ON, the battery voltage is applied to IGSW

of the ECM. The output signal from the MREL terminal of the ECM causes a current

to flow to the coil, ...

Fuel Pump Control Circuit

Fuel Pump Control Circuit

DESCRIPTION

1. w/o Smart Key System

When the engine is cranked, the starter relay drive signal output from the ignition

switch is input into the STA terminal of the ECM, and the NE signal generate ...

Other materials about Toyota Venza:

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly or camshaft timing exhaust gear assembly (See page

).

PROCEDURE

1. INSTALL NO. 2 CAMSHAF ...

Dtc Check / Clear

DTC CHECK / CLEAR

NOTICE:

When the diagnosis system is changed from normal mode to check mode or vice versa,

all DTCs and freeze frame data recorded in normal mode are cleared. Before changing

modes, always check and make a note of DTCs and freeze frame ...

Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART

If a trouble code is displayed during the DTC check, check the circuit listed

for the code in the table below (proceed to the page listed for that circuit).

HINT:

When DTC B1650/32 is detected as a result of troubleshooting f ...

0.1386

.gif)