Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONING UNIT

(See page .gif) )

)

2. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

3. REMOVE INLET NO. 2 AIR CLEANER

.gif)

4. REMOVE AIR CLEANER CAP WITH HOSE

.gif)

5. REMOVE AIR CLEANER CASE

.gif)

6. REMOVE FRONT NO. 3 EXHAUST PIPE SUB-ASSEMBLY

.gif)

7. SEPARATE MANIFOLD STAY

.gif)

8. REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY RH

.gif)

9. REMOVE EXHAUST MANIFOLD TO HEAD GASKET

.gif)

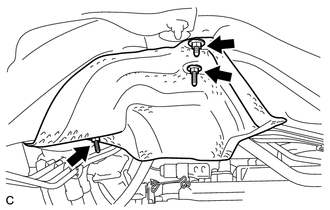

10. REMOVE FRONT NO. 1 FLOOR HEAT INSULATOR

|

(a) Remove the 3 nuts and front No. 1 floor heat insulator. |

|

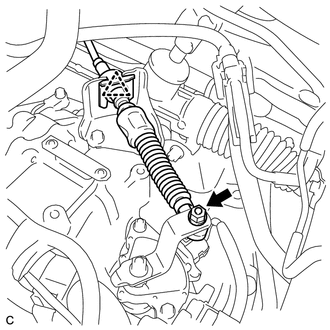

11. REMOVE TRANSMISSION CONTROL CABLE ASSEMBLY

|

(a) Remove the clip and disconnect the transmission control cable assembly from the No. 1 control cable bracket. |

|

(b) Remove the nut and transmission control cable assembly from the transmission control shaft lever.

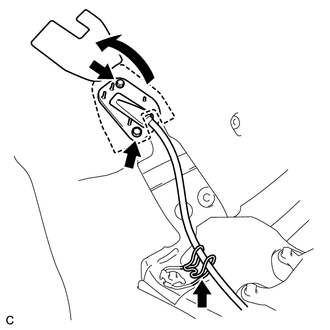

|

(c) Disconnect the transmission control cable assembly from the No. 2 transmission control cable bracket. |

|

(d) Turn back the carpet.

(e) Remove the 2 bolts and pull out the transmission control cable assembly from the body.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Adjustment

Adjustment

ADJUSTMENT

PROCEDURE

1. INSPECT SHIFT LEVER POSITION

(a) When moving the lever from P to R with the ignition switch ON and the brake

pedal depressed, make sure that the shift lever moves smoothly ...

Other materials about Toyota Venza:

Data List / Active Test

DATA LIST / ACTIVE TEST

1. DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches,

sensors, actuators and other items to be read without removing any parts. This non-intrusive

inspection can be very useful bec ...

Removal

REMOVAL

PROCEDURE

1. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/o Seat Heater System)

2. REMOVE UPPER CONSOLE PANEL SUB-ASSEMBLY (w/ Seat Heater System)

3. REMOVE NO. 2 CONSOLE BOX CARPET

4. REMOVE CONSOLE BOX ASSEMBLY

5. REMOVE AIR CONDITION ...

Disassembly

DISASSEMBLY

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page ).

2. REMOVE REAR DOOR INSIDE HANDLE BEZEL PLUG

(a) ...

0.126