Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

If automatic transaxle assembly parts are replaced, refer to Parts Replacement

Compensation Table to determine if any additional operations are necessary (See

page .gif) ).

).

PROCEDURE

1. DISCHARGE FUEL PRESSURE

See page .gif)

2. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

3. SECURE STEERING WHEEL

.gif)

4. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

5. REMOVE FRONT WHEELS

6. REMOVE NO. 1 ENGINE UNDER COVER

7. REMOVE NO. 2 ENGINE UNDER COVER

8. REMOVE FRONT FENDER APRON RH

9. REMOVE FRONT FENDER APRON LH

10. DRAIN ENGINE COOLANT

.gif)

11. DRAIN AUTOMATIC TRANSAXLE FLUID

.gif)

12. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

13. REMOVE V-BANK COVER SUB-ASSEMBLY

.gif)

14. REMOVE INLET NO. 2 AIR CLEANER

.gif)

15. REMOVE AIR CLEANER CAP WITH HOSE

.gif)

16. REMOVE AIR CLEANER CASE

.gif)

17. REMOVE BATTERY

.gif)

18. REMOVE INLET NO. 1 AIR CLEANER

.gif)

19. REMOVE INTAKE AIR SURGE TANK ASSEMBLY

See page .gif)

20. REMOVE ECM

.gif)

21. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

.gif)

22. REMOVE TCM

.gif)

23. REMOVE STARTER ASSEMBLY

.gif)

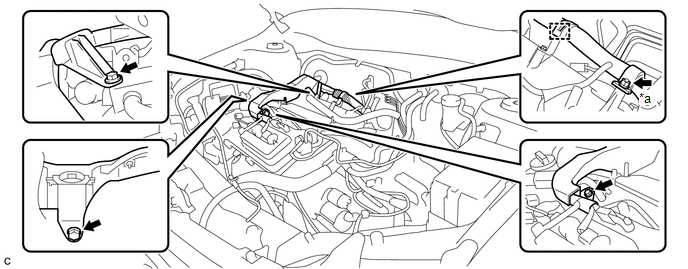

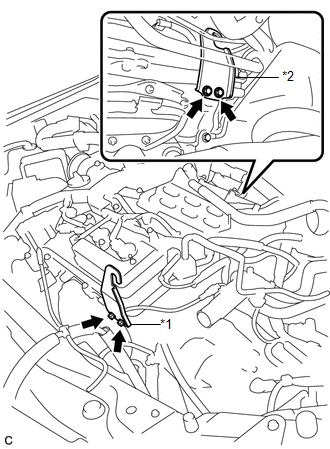

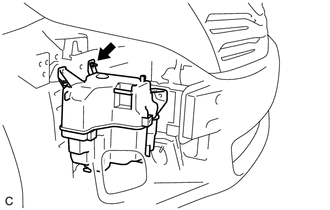

24. DISCONNECT WIRE HARNESS

|

(a) Remove the 2 bolts and disconnect the 2 wire harnesses from the automatic transaxle assembly. |

|

(b) Disconnect the park/neutral position switch assembly connector and 7 wire harness clamps from the automatic transaxle assembly.

|

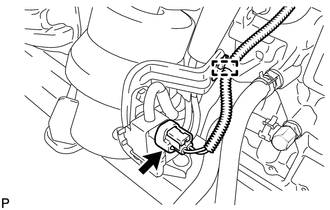

(c) Disconnect the clamp and connector. |

|

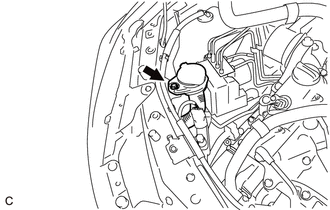

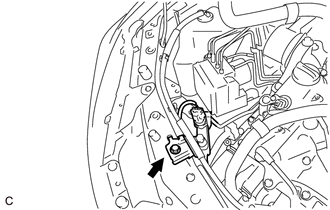

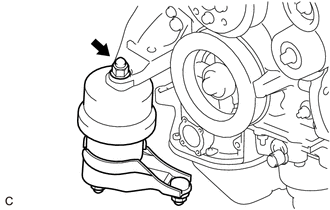

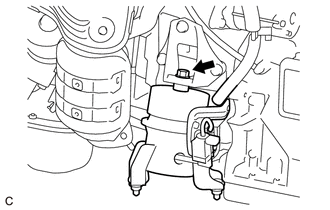

25. REMOVE FLEXIBLE HOSE BRACKET SUB-ASSEMBLY

|

(a) Disconnect the No. 1 breather plug (ATM) from the flexible hose bracket sub-assembly. |

|

(b) Remove the bolt and flexible hose bracket sub-assembly from the camshaft housing sub-assembly LH.

26. REMOVE FRONT EXHAUST PIPE ASSEMBLY

See page .gif)

27. REMOVE MANIFOLD STAY

.gif)

28. REMOVE FRONT DRIVE SHAFT ASSEMBLY

See page .gif)

29. REMOVE NO. 1 EXHAUST PIPE SUPPORT BRACKET

.gif)

30. REMOVE FLYWHEEL HOUSING UNDER COVER

.gif)

31. REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

.gif)

32. REMOVE FRONT FLOOR BRACE

.gif)

33. DISCONNECT NO. 1 RADIATOR HOSE

.gif)

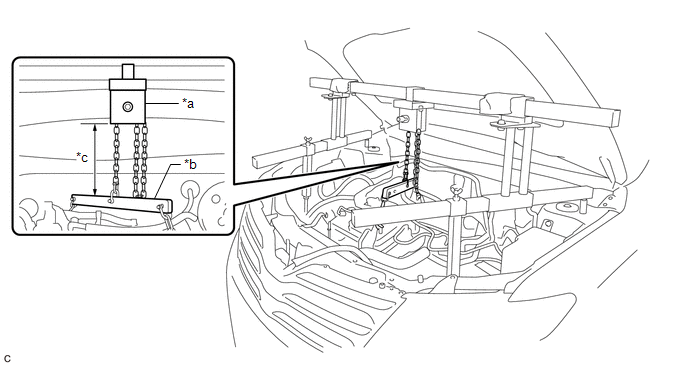

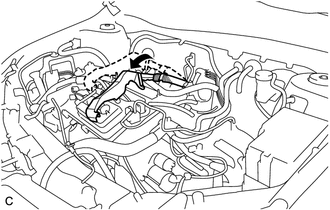

34. INSTALL ENGINE HANGERS

|

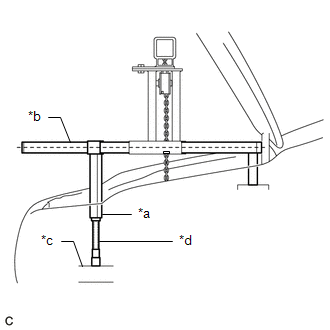

(a) Install the No. 1 and No. 2 engine hangers with the 4 bolts. Text in Illustration

Torque: 33 N·m {337 kgf·cm, 24 ft·lbf} Part No.:

|

|

35. INSTALL ENGINE SUPPORT BRIDGE

|

(a) Remove the bolt and tank cap sub-assembly. |

|

|

(b) Remove the bolt and disconnect the air conditioner tube and accessory assembly. |

|

(c) Disengage the clamp and remove the nut and 3 bolts from the engine wire.

Text in Illustration

Text in Illustration

|

*a |

Nut |

- |

- |

|

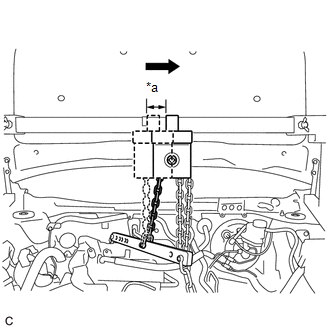

(d) Move the engine wire as shown in the illustration. NOTICE: Position the engine wire so that it will not interfere with the chains when the engine with automatic transaxle assembly is suspended. |

|

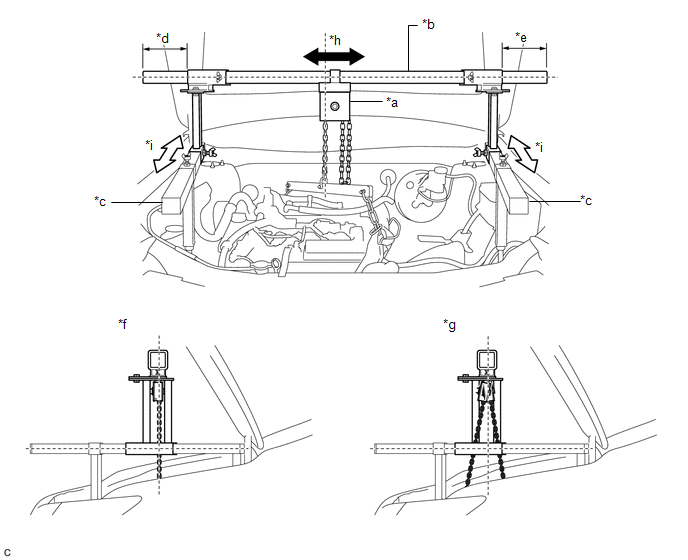

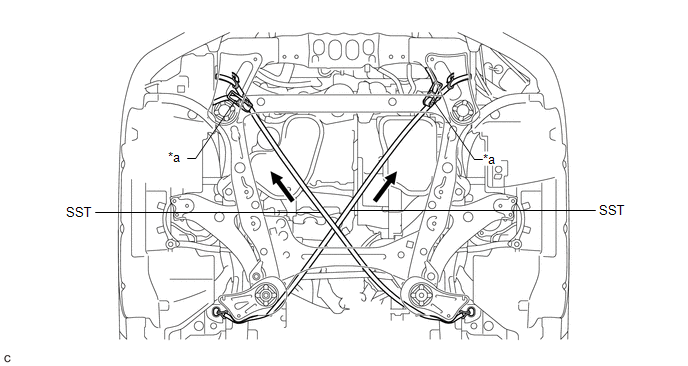

(e) Install SST to the vehicle body as shown in the illustration.

Text in Illustration

Text in Illustration

|

*a |

Support Shaft |

*b |

Side Member |

|

*c |

Cloth |

*d |

Front Side |

|

*e |

Correct |

*f |

Incorrect |

|

*g |

Front Suspension Nut |

- |

- |

SST: 09940-10020

CAUTION:

Make sure the fuse bolt is not deformed.

Text in Illustration

Text in Illustration

|

*a |

Fuse Bolt |

|

*b |

Correct |

|

*c |

Incorrect |

NOTICE:

- Prevent SST from contacting the vehicle body or windshield.

- To prevent damage to the engine hood, place pieces of cloth between the engine hood and SST.

- Lightly shake SST by hand to make sure it is securely installed while performing work.

- Set the support shafts on level surfaces.

|

(f) Turn the threaded portion of each support shaft to adjust its height and make the SST sub beams parallel to the ground. Text in Illustration

|

|

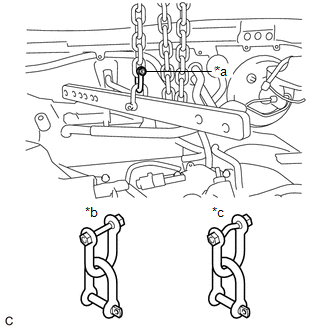

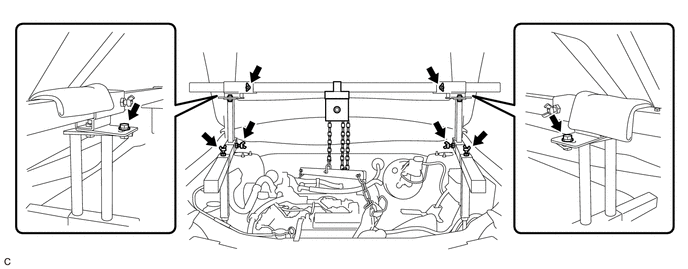

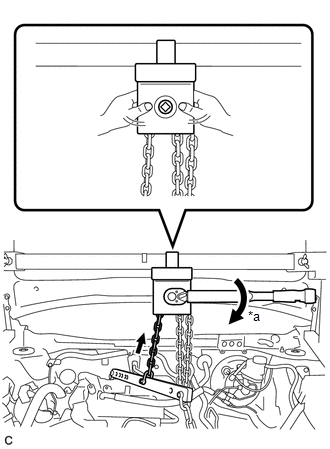

(g) Connect each chain to the division bar with the shackles at the position shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

No. 2 Engine Hanger |

*2 |

No. 1 Engine Hanger |

|

*a |

Division Bar |

*b |

Shackle |

(h) Connect the 4th link of the chain to the No. 1 engine hanger.

(i) Connect the 3rd link of the chain to the No. 2 engine hanger.

(j) Make sure the distance between the chain block assembly and division bar is 50 mm (1.97 in.) or more.

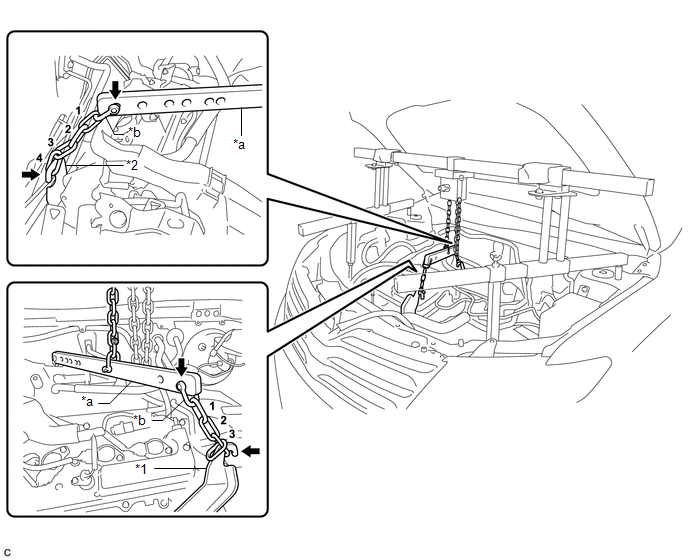

Text in Illustration

Text in Illustration

|

*a |

Chain Block Assembly |

*b |

Division Bar |

|

*c |

50 mm (1.97 in.) or more |

- |

- |

(k) Adjust the position of the chain block assembly so that the chain is perpendicular to the SST main beam and sub beams as shown in the illustration.

Text in Illustration

Text in Illustration

|

*a |

Chain Block Assembly |

*b |

Main Beam |

|

*c |

Sub Beam |

*d |

Dimension (A) |

|

*e |

Dimension (B) |

*f |

Correct |

|

*g |

Incorrect |

*h |

Right to Left Adjustment |

|

*i |

Front to Rear Adjustment |

- |

- |

CAUTION:

To prevent the engine with automatic transaxle assembly from falling, make sure that the dimension (A) and dimension (B) are equal.

(l) Tighten the 6 wing bolts and 2 bolts.

Torque:

for Bolt :

30 N·m {306 kgf·cm, 22 ft·lbf}

|

(m) Move the chain block assembly approximately 50 mm (1.97 in.) as shown in the illustration. Text in Illustration

|

|

|

(n) Tighten the chain block assembly until it cannot be moved any further by hand. Text in Illustration

NOTICE:

|

|

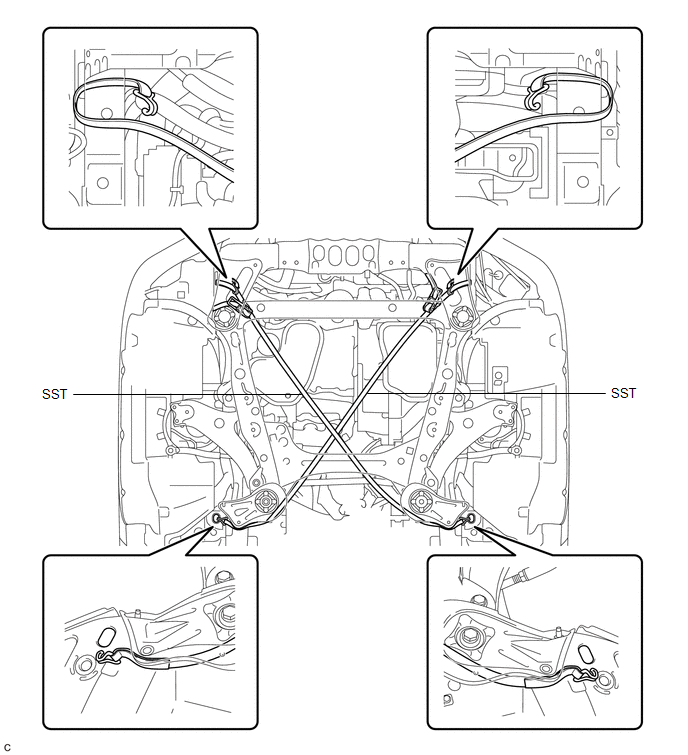

36. INSTALL BELT

|

(a) Remove the 2 bolts. |

|

|

(b) Loosen the nut and disconnect the windshield washer jar assembly from the vehicle body. NOTICE: Do not remove the nut. |

|

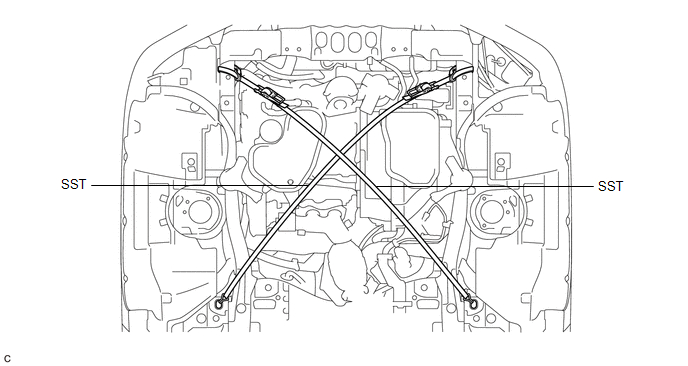

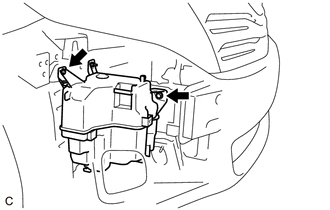

(c) Install SST to the vehicle body as shown in the illustration.

SST: 09727-00110

(d) Using the SST ratchet buckle, tighten the SST belt until there is no slack.

Text in Illustration

Text in Illustration

|

*a |

Ratchet Buckle |

- |

- |

37. REMOVE FRONT FRAME ASSEMBLY

See page .gif)

38. REMOVE ENGINE MOUNTING INSULATOR RH

|

(a) Remove the nut and engine mounting insulator RH from the engine mounting bracket RH. |

|

39. INSTALL SUPPORT BAR

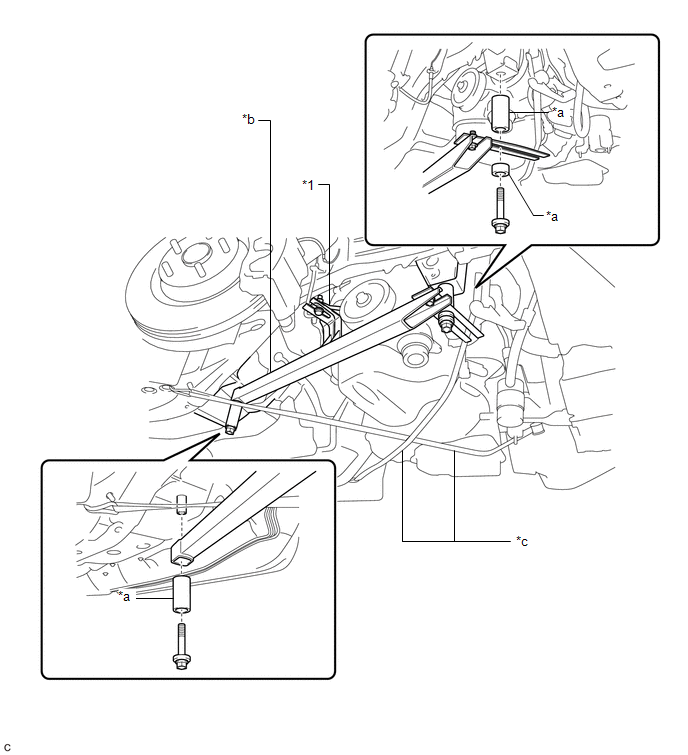

(a) Install the SST (support bar) to the vehicle body with the 2 bolts as shown in the illustration.

Text in Illustration

Text in Illustration

|

*1 |

Engine Mounting Bracket RH |

- |

- |

|

*a |

Spacer |

*b |

SST (Support Bar) |

|

*c |

SST (Belt) |

- |

- |

SST: 09944-10020

CAUTION:

To prevent the engine with automatic transaxle assembly from falling while servicing, do not remove SST (belt).

(b) Install the bolt to the engine mounting bracket RH.

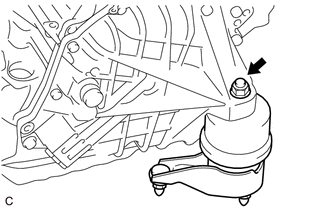

40. REMOVE FRONT ENGINE MOUNTING INSULATOR ASSEMBLY

|

(a) Remove the bolt and front engine mounting insulator assembly from the front engine mounting bracket. |

|

41. REMOVE ENGINE MOUNTING INSULATOR LH

|

(a) Remove the nut and engine mounting insulator LH from the automatic transaxle assembly. |

|

42. DISCONNECT OUTLET NO. 1 OIL COOLER HOSE

|

(a) Slide the clip and disconnect the outlet No. 1 oil cooler hose from the automatic transaxle assembly. |

|

43. DISCONNECT INLET NO. 1 OIL COOLER HOSE

|

(a) Slide the clip and disconnect the inlet No. 1 oil cooler hose from the automatic transaxle assembly. |

|

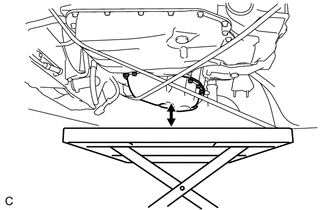

44. SUPPORT ENGINE ASSEMBLY

|

(a) Set an engine lifter. CAUTION: To prevent the engine with automatic transaxle assembly from falling while servicing, do not remove SST. NOTICE: Make sure that there is a clearance between the engine oil pan assembly and engine lifter. |

|

45. REMOVE BELT

(a) Remove SST from the vehicle body.

46. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

(a) Support the automatic transaxle assembly with a transmission jack.

NOTICE:

- In order to protect the automatic transaxle oil pan sub-assembly, place attachments on the transmission jack.

- Make sure that the attachments and automatic transaxle oil pan sub-assembly are centered on the transmission jack.

- To prevent the automatic transaxle oil pan sub-assembly from being deformed, do not place any attachments under the automatic transaxle oil pan sub-assembly.

|

(b) Remove the 11 bolts and automatic transaxle assembly from the engine assembly. NOTICE:

|

|

47. REMOVE TORQUE CONVERTER ASSEMBLY

(a) Remove the torque converter assembly from the automatic transaxle assembly.

48. REMOVE FRONT ENGINE MOUNTING BRACKET

|

(a) Remove the 3 bolts and front engine mounting bracket from the automatic transaxle assembly. |

|

49. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the 4 bolts and 4 wire harness clamp brackets from the automatic transaxle assembly. |

|

50. REMOVE NO. 1 TRANSMISSION CONTROL CABLE BRACKET

|

(a) Remove the 2 bolts and No. 1 transmission control cable bracket from the automatic transaxle assembly. |

|

51. REMOVE SPEEDOMETER DRIVEN HOLE (ATM) COVER SUB-ASSEMBLY

|

(a) Remove the bolt and speedometer driven hole (ATM) cover sub-assembly from the automatic transaxle assembly. |

|

(b) Remove the O-ring from the speedometer driven hole (ATM) cover sub-assembly.

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY

2. INSTALL TORQUE CONVERTER ASSEMBLY

(a) Engage the splines of the input shaft and turbine runner.

...

Other materials about Toyota Venza:

Door Courtesy Switch Circuit

DESCRIPTION

The main body ECU (driver side junction block assembly) detects the condition

of the door courtesy light switch.

WIRING DIAGRAM

PROCEDURE

1.

READ VALUE USING TECHSTREAM

(a) Connect the Techstream to the DLC3 ...

System Diagram

SYSTEM DIAGRAM

Communication Table

Transmitting ECU

Receiving ECU

Signal

Communication Method

Air Conditioning Control Assembly

Air Conditioning Amplifier Assembly

Rear windo ...

Installation

INSTALLATION

PROCEDURE

1. INSTALL REAR POWER POINT SOCKET COVER

(a) Engage the 2 claws to install the rear power point socket cover.

2. INSTALL REAR POWER POINT SOCKET ASSEMBLY

(a) Engag ...

0.1213

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)