Toyota Venza: Removal

REMOVAL

CAUTION / NOTICE / HINT

NOTICE:

If automatic transaxle assembly parts are replaced, refer to Parts Replacement

Compensation Table to determine if any additional operations are necessary (See

page .gif) ).

).

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

See the steps from "Recover Refrigerant From Refrigeration System" through "Remove

Engine Assembly with Transaxle" (See page .gif) ).

).

2. DISCONNECT FRONT CROSSMEMBER SUB-ASSEMBLY

.gif)

3. REMOVE STARTER ASSEMBLY

.gif)

4. REMOVE MANIFOLD STAY

.gif)

5. REMOVE TCM

.gif)

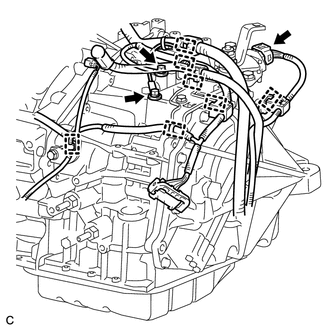

6. SEPARATE WIRE HARNESS

|

(a) Remove the 2 bolts and disconnect the 2 wire harnesses from the automatic transaxle assembly. |

|

(b) Separate the park/neutral position switch assembly connector and 7 wire harness clamps from the automatic transaxle assembly.

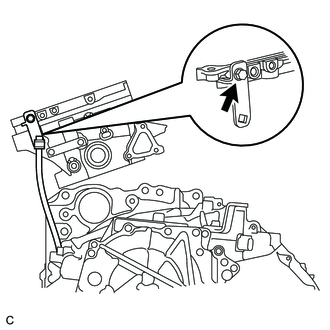

7. REMOVE FLEXIBLE HOSE BRACKET SUB-ASSEMBLY

|

(a) Remove the bolt and flexible hose bracket sub-assembly from the camshaft housing sub-assembly LH. |

|

(b) Remove the No. 1 breather plug (ATM) from the flexible hose bracket sub-assembly.

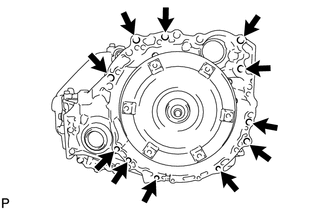

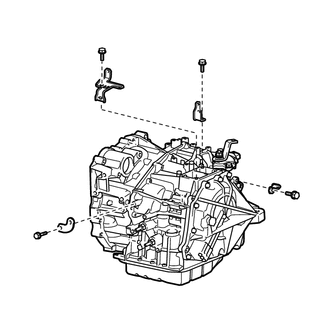

8. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

|

(a) Remove the 11 bolts and automatic transaxle assembly from the engine assembly. NOTICE: To prevent damage to the 2 knock pins, do not pry between the automatic transaxle assembly and engine assembly. |

|

9. REMOVE TORQUE CONVERTER ASSEMBLY

(a) Remove the torque converter assembly from the automatic transaxle assembly.

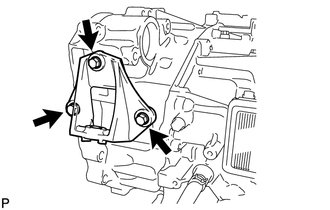

10. REMOVE FRONT ENGINE MOUNTING BRACKET

|

(a) Remove the 3 bolts and front engine mounting bracket from the automatic transaxle assembly. |

|

11. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the 4 bolts and 4 wire harness clamp brackets from the automatic transaxle assembly. |

|

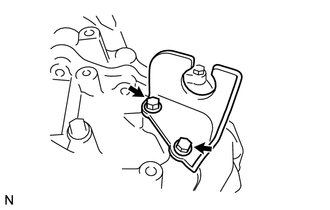

12. REMOVE NO. 1 TRANSMISSION CONTROL CABLE BRACKET

|

(a) Remove the 2 bolts and No. 1 transmission control cable bracket from the automatic transaxle assembly. |

|

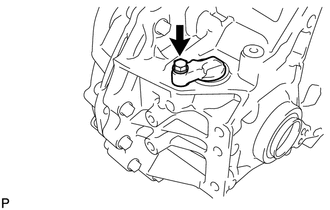

13. REMOVE SPEEDOMETER DRIVEN HOLE (ATM) COVER SUB-ASSEMBLY

|

(a) Remove the bolt and speedometer driven hole (ATM) cover sub-assembly from the automatic transaxle assembly. |

|

(b) Remove the O-ring from the speedometer driven hole (ATM) cover sub-assembly.

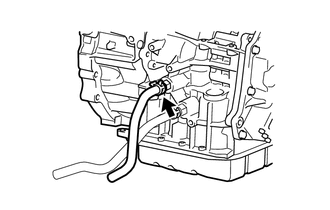

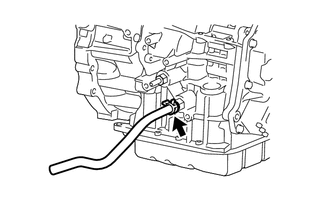

14. REMOVE NO. 1 OIL COOLER OUTLET HOSE

|

(a) Slide the clip and disconnect the No. 1 oil cooler outlet hose from the automatic transaxle assembly. |

|

15. REMOVE NO. 1 OIL COOLER INLET HOSE

|

(a) Slide the clip and disconnect the No. 1 oil cooler inlet hose from the automatic transaxle assembly. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY

2. INSTALL TORQUE CONVERTER ASSEMBLY

(a) Engage the splines of the input shaft and turbine runner.

...

Other materials about Toyota Venza:

Front Blower Motor

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL FRONT BLOWER MOTOR SUB-ASSEMBLY

(a) Install the front blower motor sub-assembly with the 3 screws.

(b) Con ...

Back Door Entry Unlock Function does not Operate

DESCRIPTION

If the entry back door open function does not operate but the back door entry

lock function operates, the communication between the vehicle and key is normal.

As a faulty part, the back door open switch circuit (from the back door opener switc ...

Fail-safe Chart

FAIL-SAFE CHART

HINT:

If the following conditions are detected while the cruise control is in operation,

the system clears the stored vehicle speed in the ECM and cancels the cruise control

operation.

Vehicle Condition

Auto Cancel ...

0.1177