Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DRAIN DIFFERENTIAL OIL

|

(a) Using a 10 mm hexagon wrench, remove the rear differential carrier cover plug and gasket. |

|

|

(b) Using a 10 mm hexagon wrench, remove the rear differential drain plug and gasket to drain the differential oil. |

|

2. REMOVE REAR WHEELS

3. REMOVE CENTER EXHAUST PIPE ASSEMBLY

(a) Remove the center exhaust pipe assembly.

HINT:

Refer to the instructions for Removal of the exhaust pipe (See page

.gif) for 2GR-FE,

for 2GR-FE, .gif)

for 1AR-FE).

4. REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

.gif)

5. SEPARATE REAR SPEED SENSOR LH

.gif)

6. SEPARATE REAR SPEED SENSOR RH

.gif)

7. REMOVE REAR AXLE SHAFT NUT LH

.gif)

8. REMOVE REAR AXLE SHAFT NUT RH

.gif)

9. SEPARATE NO. 3 PARKING BRAKE CABLE ASSEMBLY

.gif)

10. SEPARATE NO. 2 PARKING BRAKE CABLE ASSEMBLY

.gif)

11. REMOVE NO. 1 FLOOR UNDER COVER

.gif)

12. REMOVE REAR STRUT ROD ASSEMBLY LH

.gif)

13. REMOVE REAR STRUT ROD ASSEMBLY RH

.gif)

14. REMOVE REAR HEIGHT CONTROL SENSOR SUB-ASSEMBLY (w/ HID Headlight System)

.gif)

15. REMOVE REAR NO. 2 SUSPENSION ARM ASSEMBLY LH

.gif)

16. REMOVE REAR NO. 2 SUSPENSION ARM ASSEMBLY RH

.gif)

17. SEPARATE REAR NO. 1 SUSPENSION ARM ASSEMBLY LH

.gif)

18. SEPARATE REAR NO. 1 SUSPENSION ARM ASSEMBLY RH

.gif)

19. REMOVE REAR DRIVE SHAFT ASSEMBLY LH

.gif)

20. REMOVE REAR DRIVE SHAFT SNAP RING LH

.gif)

21. REMOVE REAR DRIVE SHAFT ASSEMBLY RH

.gif)

22. REMOVE REAR DRIVE SHAFT SNAP RING RH

.gif)

23. SEPARATE NO. 3 FLOOR WIRE (w/ HID Headlight System)

.gif)

24. SEPARATE FRAME WIRE

.gif)

25. REMOVE REAR SUSPENSION MEMBER

.gif)

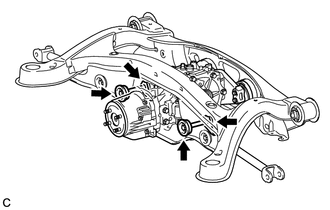

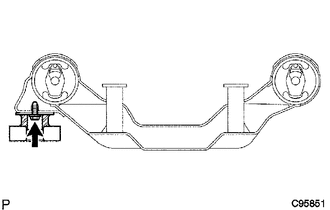

26. REMOVE REAR DIFFERENTIAL CARRIER ASSEMBLY WITH DIFFERENTIAL SUPPORT

|

(a) Remove the 2 bolts and 2 nuts. HINT: The nuts have tabs to prevent them from rotating. |

|

|

(b) Remove the 3 rear mounting bolts and rear differential carrier assembly with differential support from the rear suspension member assembly. |

|

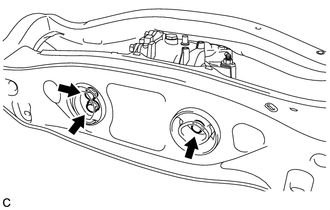

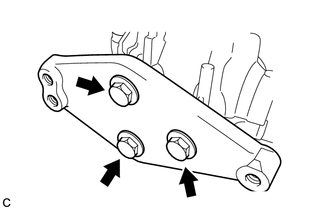

27. REMOVE DIFFERENTIAL SUPPORT

|

(a) Remove the 3 bolts and differential support. |

|

28. REMOVE REAR NO. 1 DIFFERENTIAL SUPPORT

|

(a) Remove the 2 bolts, 2 nuts and rear No. 1 differential support. HINT: The nuts have tabs to prevent them from rotating. |

|

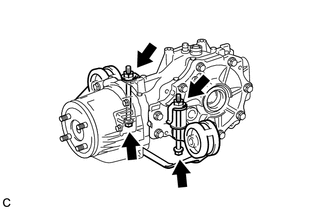

29. REMOVE REAR DIFFERENTIAL DYNAMIC DAMPER

HINT:

This step should be performed only when the rear differential dynamic damper is being replaced.

|

(a) Remove the bolt and rear differential dynamic damper. |

|

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

ILLUSTRATION

...

Disassembly

Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

HINT:

Use an overhaul stand as necessary.

PROCEDURE

1. REMOVE REAR DIFFERENTIAL FILLER PLUG

(a) Remove the rear differential filler plug and gasket ...

Other materials about Toyota Venza:

Transmission Wire(when Using The Engine Support Bridge)

Components

COMPONENTS

ILLUSTRATION

Installation

INSTALLATION

PROCEDURE

1. INSTALL TRANSMISSION WIRE

(a) Coat the O-ring with ATF.

(b) Coat the bolt with ATF.

(c) Install the transmission ...

Fuel Sender Open Detected (B1500)

DESCRIPTION

This DTC is output when the combination meter assembly detects a fuel sender

gauge malfunction via the direct line.

DTC No.

DTC Detection Condition

Trouble Area

B1500

When either of t ...

Hydraulic Test

HYDRAULIC TEST

1. PERFORM HYDRAULIC TEST

(a) Measure the line pressure.

CAUTION:

The line pressure test should always be carried out with at least 2 people. One

person should observe the condition of wheels and wheel chocks while the other is

perform ...

0.156

.png)

.png)