Toyota Venza: Installation

INSTALLATION

PROCEDURE

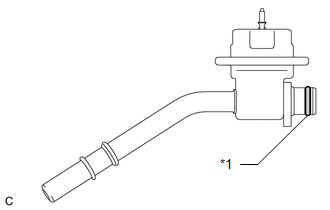

1. INSTALL FUEL PRESSURE PULSATION DAMPER ASSEMBLY

|

(a) Apply a light coat of gasoline or spindle oil to a new O-ring. Text in Illustration

|

|

(b) Install the O-ring to the fuel pressure pulsation damper assembly.

(c) Install the fuel pressure pulsation damper assembly with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

Make sure that the O-ring is not cracked or jammed when installing the damper.

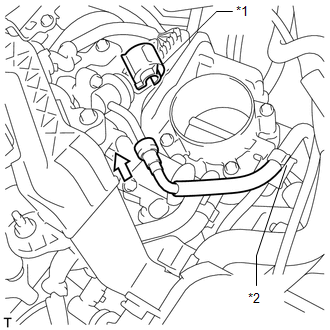

2. INSTALL FUEL TUBE SUB-ASSEMBLY

Text in Illustration

Text in Illustration

|

*1 |

No. 2 Fuel Pipe Clamp |

|

*2 |

Fuel Hose Clamp |

.png) |

Push |

(a) Connect the fuel tube.

(b) Push the fuel tube connector until it makes a "click" sound.

(c) Install a new No. 2 fuel pipe clamp.

(d) Push the tube connector into the pipe until the tube connector makes a "click" sound.

.png) Text in Illustration

Text in Illustration

|

*1 |

Fuel Pipe |

|

*2 |

Fuel Tube Connector |

|

*3 |

Nylon Tube |

|

*4 |

O-ring |

|

*5 |

Retainer |

.png) |

Push |

NOTICE:

- Before connecting the connector and fuel pipe, check that there is no damage or foreign matter on the connecting part of the fuel pipe.

- After connecting the fuel tube connector and fuel pipe, check that they are securely connected by trying to pull them apart.

(e) Install the No. 1 fuel pipe clamp.

(f) Install the fuel tube sub-assembly to the fuel hose clamp.

3. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

.gif)

4. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

.gif)

5. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

6. INSTALL OUTER COWL TOP PANEL

.gif)

7. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

(a) Install the windshield wiper motor and link assembly (See page

.gif) ).

).

8. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

9. INSPECT FOR FUEL LEAK

.gif)

Removal

Removal

REMOVAL

PROCEDURE

1. DISCHARGE FUEL SYSTEM PRESSURE

HINT:

See page

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized ...

Other materials about Toyota Venza:

Customize Parameters

CUSTOMIZE PARAMETERS

1. CUSTOMIZING FUNCTION WITH TECHSTREAM (REFERENCE)

HINT:

The following items can be customized.

NOTICE:

When the customer requests a change in a function, first make sure that

the function can be customized.

Record th ...

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT BRAKE BOOSTER ASSEMBLY

(a) Airtightness check

(1) Start the engine and stop it after 1 or 2 minutes. Slowly depress

the brake pedal several times.

HINT:

If the pedal can be depressed to the ...

Removal

REMOVAL

PROCEDURE

1. REMOVE REAR SEAT HEADREST ASSEMBLY

2. REMOVE REAR SEAT CENTER HEADREST ASSEMBLY

3. REMOVE REAR SEAT INNER TRACK BRACKET COVER

4. REMOVE REAR SEAT OUTER TRACK BRACKET COVER

5. DISCONNECT REAR SEAT RECLINING CONTROL CABLE S ...

0.1505