Toyota Venza: Removal

REMOVAL

PROCEDURE

1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable

is reconnected (See page .gif) ).

).

2. REMOVE FRONT WHEEL RH

3. REMOVE NO. 1 ENGINE UNDER COVER

4. SEPARATE FRONT FENDER LINER RH

5. REMOVE FRONT FENDER APRON SEAL RH

.gif)

6. REMOVE COOL AIR INTAKE DUCT SEAL

.gif)

7. REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

.gif)

8. REMOVE INLET AIR CLEANER ASSEMBLY

.gif)

9. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

|

(a) Disconnect the mass air flow meter connector and separate the wire harness clamp from the air cleaner cap. |

|

(b) Loosen the hose clamp and disconnect the air cleaner hose.

|

(c) Remove the 2 bolts and air cleaner cap sub-assembly. |

|

10. REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

.gif)

11. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

.gif)

12. REMOVE NO. 2 ENGINE MOUNTING STAY RH

.gif)

13. REMOVE ENGINE MOVING CONTROL ROD

.gif)

14. DISCONNECT VENTILATION HOSE ASSEMBLY

|

(a) Disconnect the ventilation hose from the cylinder head cover. |

|

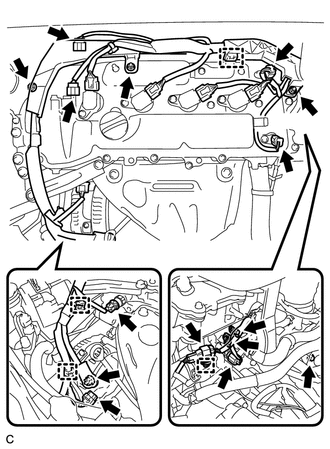

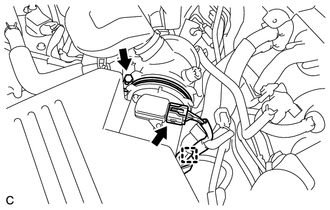

15. DISCONNECT ENGINE WIRE

|

(a) Disconnect the connectors and clamps, remove the bolts and nuts and disconnect the engine wire from the engine. |

|

16. REMOVE IGNITION COIL ASSEMBLY

.gif)

17. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

.gif)

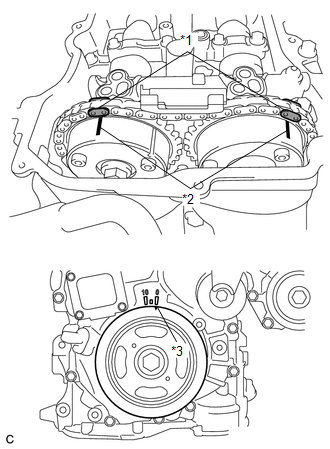

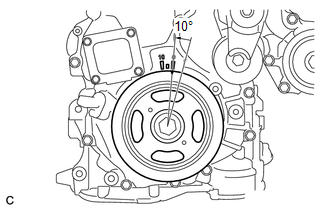

18. SET NO. 1 CYLINDER TO TDC/COMPRESSION

|

(a) Turn the crankshaft pulley until its timing notch (groove) and the timing mark "0" of the timing chain cover are aligned. Text in Illustration

|

|

(b) Check that each matchmark of the camshaft timing gear and camshaft timing exhaust gear are aligned with each matchmark located as shown in the illustration. If not, turn the crankshaft 1 revolution (360°) to align the timing marks as shown in the illustration.

(c) Place paint marks on the chain in alignment with the timing marks on the camshaft timing gear and camshaft timing exhaust gear.

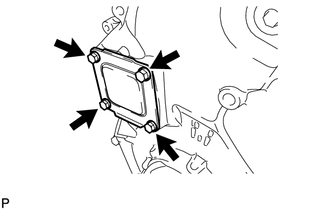

19. REMOVE TIMING CHAIN COVER PLATE

|

(a) Remove the 4 bolts, timing chain cover plate and gasket. |

|

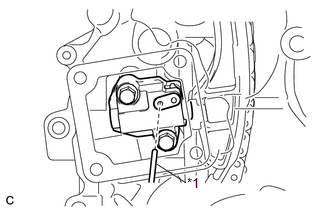

20. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

|

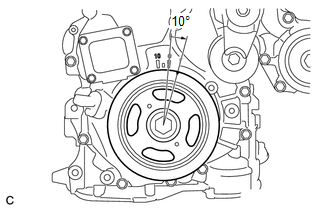

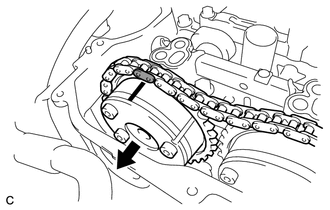

(a) Turn the crankshaft approximately 10° clockwise. |

|

|

(b) Turn the crankshaft approximately 10° counterclockwise. |

|

|

(c) Align the holes of the stopper plate and tensioner, and insert a pin into the stopper plate hole to lock the tensioner. Text in Illustration

|

|

|

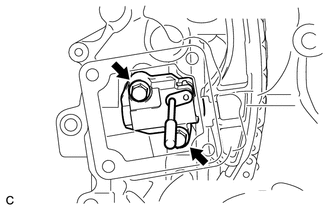

(d) Turn the crankshaft approximately 10° clockwise. |

|

|

(e) Remove the 2 bolts, chain tensioner and gasket. NOTICE: Make sure not to drop the gasket inside the timing chain cover. |

|

|

(f) Turn the crankshaft approximately 10° counterclockwise. |

|

21. REMOVE TIMING CHAIN GUIDE

.gif)

22. REMOVE TIMING CHAIN COVER TIGHT PLUG

.gif)

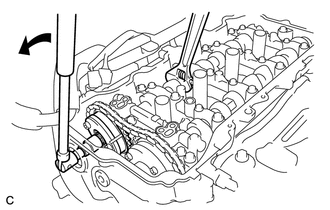

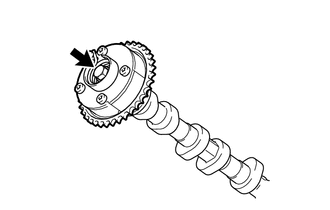

23. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

|

(a) Hold the hexagonal portion of the camshaft with a wrench and remove the bolt from the camshaft. NOTICE: Be careful not to damage the cylinder head or spark plug tube with the wrench. |

|

|

(b) Separate the camshaft timing gear assembly from the camshaft. |

|

|

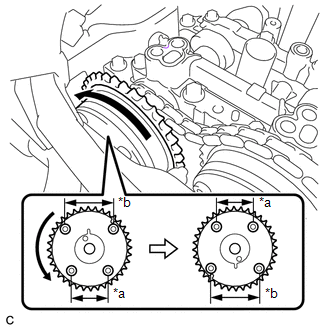

(c) Remove the timing chain from the camshaft timing gear assembly, and turn the camshaft timing gear assembly approximately 180°. Text in Illustration

|

|

|

(d) Remove the camshaft timing gear assembly. NOTICE: Do not disassemble the camshaft timing gear. |

|

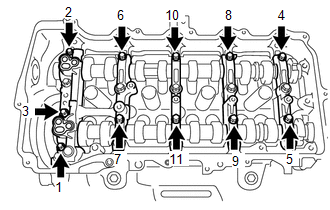

24. REMOVE CAMSHAFT BEARING CAP

|

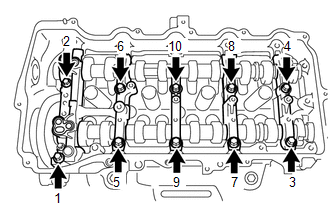

(a) Using several steps, remove the 11 bearing cap bolts in the sequence shown in the illustration. |

|

|

(b) Using several steps, remove the 10 bearing cap bolts in the sequence shown in the illustration. |

|

(c) Remove the 5 bearing caps.

HINT:

Arrange the removed parts in the correct order.

25. REMOVE CAMSHAFT

|

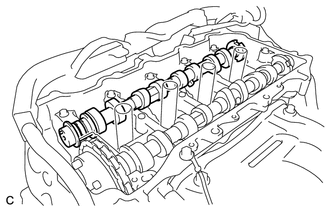

(a) Remove the camshaft from the camshaft housing. |

|

26. REMOVE NO. 2 CAMSHAFT

|

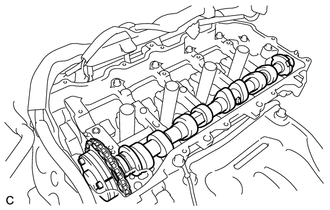

(a) Hold up the chain and remove the No. 2 camshaft from the camshaft housing. |

|

|

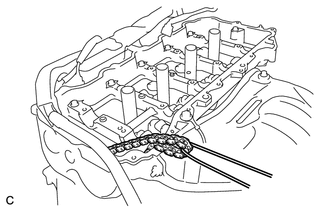

(b) Suspend the chain with a string or equivalent as shown in the illustration. NOTICE: Be careful not to drop the chain inside the timing chain cover. |

|

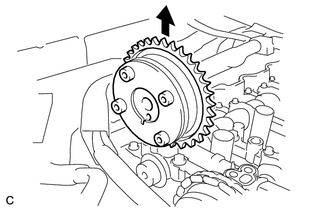

27. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

|

(a) Remove the flange bolt and camshaft timing exhaust gear assembly. NOTICE: Do not disassemble the camshaft timing exhaust gear. |

|

28. REMOVE OIL CONTROL VALVE FILTER

.gif)

29. REMOVE NO. 1 CAMSHAFT BEARING

.gif)

30. REMOVE NO. 2 CAMSHAFT BEARING

.gif)

Components

Components

COMPONENTS

ILLUSTRATION

ILLUSTRATION

...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the camshaft, No. 2 camshaft,

camshaft timing gear assembly or camshaft timing exhaust gear ...

Other materials about Toyota Venza:

Relay

On-vehicle Inspection

ON-VEHICLE INSPECTION

PROCEDURE

1. INSPECT HORN RELAY (ENGINE ROOM JUNCTION BLOCK ASSEMBLY)

(a) Remove the engine room junction block assembly from the engine room

relay block (See page ).

...

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms.

If multiple suspected areas are listed, the potential causes of the symptoms

are listed in order of probability in the "Suspected Area" ...

Removal

REMOVAL

CAUTION / NOTICE / HINT

HINT:

Use the same procedure for the RH side and LH side.

The procedure listed below is for the LH side.

PROCEDURE

1. PRECAUTION

CAUTION:

Be sure to read Precaution thoroughly before servicing (See page

...

0.1412

.png)

.png)