Toyota Venza: Removal

REMOVAL

PROCEDURE

1. REMOVE WHEEL ASSEMBLY

2. REMOVE TIRE PRESSURE WARNING VALVE AND TRANSMITTER

(a) Remove the tire valve cap.

NOTICE:

Keep the removed tire valve cap.

(b) Remove the valve core to release the air from the tire.

NOTICE:

Make sure that a sufficient amount of air has been released.

(c) Remove the nut and washer.

(d) Drop the tire pressure warning valve and transmitter with grommet into the tire.

HINT:

The grommet may remain attached to the rim.

|

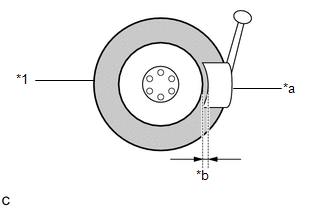

(e) Using a tire remover, remove the tire from the disc wheel. Text in Illustration

NOTICE:

|

|

(f) Take out the tire pressure warning valve and transmitter with grommet from the tire.

(g) Remove the grommet from the tire pressure warning valve and transmitter.

Components

Components

COMPONENTS

ILLUSTRATION

...

Installation

Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

Always use a new grommet and valve core when installing the tire pressure

warning valve and transmitter.

Check that the washer and nut a ...

Other materials about Toyota Venza:

Back Door cannot be Opened

DESCRIPTION

When the back door cannot be opened, one of the following may be malfunctioning:

1) power back door ECU (power back door motor unit)*1 or back door closer ECU (multiplex

network door ECU)*2, 2) back door lock assembly, 3) back door opener swit ...

Vehicle Specifications have not been Stored (B2451)

DESCRIPTION

The headlight leveling ECU assembly stores this DTC if the vehicle specifications

have not been stored in the ECU.

HINT:

The vehicle specifications are stored in the ECU at the factory.

DTC No.

DTC Detecting Condition

...

Mass Air Flow Meter

Components

COMPONENTS

ILLUSTRATION

On-vehicle Inspection

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

Perform the mass air flow meter inspection according to the procedure

below.

Only replace the mass air flow meter when t ...

0.1591